The Development of Prototype Data Delivery System Based on LoRa and Mesh Topology

on

JURNAL ILMIAH MERPATI VOL. 10, NO. 1 APRIL 2022

p-ISSN: 2252-3006

e-ISSN: 2685-2411

The Development of Prototype Data Delivery System Based on LoRa and Mesh Topology

Dewa Gede Kesuma Yogaa1, I Made Agus Dwi Suarjayaa2, I Putu Agus Eka Pratamaa3 aInformation Technology Department, Faculty of Engineering, Udayana University, e-mail: 1dode.yoga98@gmail.com, 2agussuarjaya@it.unud.ac.id, 3eka.pratama@unud.ac.id

Abstrak

Penelitian ini bertujuan untuk membangun pengembangan prototipe pada sistem pengiriman data menggunakan protokol komunikasi LoRa dengan menerapkan topologi mesh pada wilayah yang sulit dijangkau, dimana perangkat IoT pertama memiliki peran sebagai gateway antara perangkat IoT dengan server. Kemudian perangkat IoT kedua memiliki peran sebagai gateway antara perangkat IoT dan dalam penelitian ini menggunakan suatu aplikasi WEB interface yang dioperasikan oleh user untuk mengontrol dan monitoring kondisi perangkat. Penelitian ini menggunakan mikrokontroler NodeMCU ESP8266 yang digunakan pada perangkat IoT pertama, kemudian dalam penelitian ini juga menggunakan mikrokontroler Arduino UNO yang digunakan pada setiap perangkat IoT yang ditujukan untuk melakukan proses pengiriman data antar perangkat IoT. Kemudian penggunaan modul LoRa pada penelitian ini digunakan sebagai media komunikasi antara perangkat IoT, dan penggunaan sensor suhu DS18B20 digunakan sebagai parameter pengiriman data. Berdasarkan ujicoba yang telah dilakukan didapatkan hasil prototipe sistem bekerja dengan baik sesuai dengan fitur yang tersedia.

Kata kunci: Arduino Uno, IoT, NodeMCU.

Abstract

This study aims to build a prototype development on a data delivery system using the LoRa communication protocol by applying a mesh topology in hard-to-reach areas, where the first IoT device has a role as a gateway between IoT devices and servers. Then the second IoT device has a role as a gateway between IoT devices and in this study uses a WEB interface application that is operated by the user to control and monitor the condition of the device. This study uses the NodeMCU ESP8266 microcontroller which is used on the first IoT device, then in this study also uses the Arduino UNO microcontroller which is used on every IoT device which is intended to carry out the process of sending data between IoT devices. Then the use of the LoRa module in this study is used as a communication medium between IoT devices, and the use of the DS18B20 temperature sensor is used as a data transmission parameter. Based on the trials that have been carried out, the results of the prototype system work well according to the available features.

Keywords: Arduino Uno, IoT, NodeMCU.

Nowadays, there are various advances in all areas of life to make it easier for humans to carry out their activities, one of the advances that really helps make human life easier is technological progress. As we already know, the progress and development of this technology plays a very important role in the daily activities of mankind, as a relevant example is the progress in the field of communication technology. Communication technology is widely applied in various fields such as education, military, and industry [1]. Communication technology is known as a process of sending messages between one point to another that is useful for obtaining or exchanging information regardless of the distance, in addition, this communication technology is also often used on industrial 4.0 devices [2].

The development of the industrial world today is known as the industrial 4.0 concept, this concept has the characteristics of technology that integrates with society, especially with the

human body such as sensors, robotics, 3D printing, the internet, to virtual and physical systems that can communicate with each other. Communication technology has a very big role in the development of industry 4.0, because to increase productivity, efficiency, and decision analysis, real time monitoring is needed. In addition, communication technology in the industrial world is used as a means of remote control, with the use of communication technology it can make the devices used to be connected to each other so that these devices run automatically with the control system and are more efficient, thus making human work easier and more efficient. especially in the industrial sector [3].

The internet is used as a means of communication, namely between devices and devices, devices with humans, and humans with humans. Internet of Things or often called IoT is part of the development of technology in the field of communication which is widely used in industry 4.0, this technology is an integrated part of the future internet that can be used as a dynamic global network infrastructure with its own configuration capabilities based on communication standards and protocols. IoT operates where physical and virtual objects have physical identities and attributes, and are perfectly integrated into information networks [4]. However, the obstacle that often occurs in the implementation of communication between devices is the distance between the devices themselves, the communication distance between devices is quite short, which makes an industry need a large enough budget just to purchase equipment so that the devices used are within a radius.

With these problems, a solution arises in order to be able to carry out a communication with a long enough distance and be able to minimize the cost budget in building a network infrastructure. IoT (Internet of Thing) technology is the answer to these problems because in its application, IoT technology is able to communicate over long distances by utilizing radio waves as an intermediary. In addition, this study uses the LoRa module as a medium for this communication. LoRa is a term that refers to a new communication technology which is a breakthrough from LPWAN technology (low power wide area network), in the use of this technology, it is able to communicate over long distances and only requires few resources. With the LoRa technology, it is hoped that it can correct the shortcomings of the existing data transmission system in the previous technology, because the previous technology had quite a lot of shortcomings, such as its reach that was not far enough and also required a lot of resources or wasted resources [5].

In this study, using the WEB interface application found on a computer or laptop that can be used by users to control and monitor the condition of electronic devices located at a long distance. Where the location of the first IoT device that serves as a gateway between IoT devices and the server is within the reach of the internet network and this first IoT device is equipped with a NodeMCU ESP8266 microcontroller which is able to connect IoT devices to the server, using the internet network as a connecting medium. The use of the Arduino UNO microcontroller in this study was implemented on an IoT device that functions to carry out the process of sending data between IoT devices and is equipped with a supporting component of the DS18B20 temperature sensor which is used as a data transmission parameter. As a note, each IoT device is paired with a LoRa module which is useful for carrying out the communication process between IoT devices.

Based on a brief explanation of the background above, this research will explain the process of "Development of Prototype Data Delivery System Based on LoRa and Mesh Topology". This study focuses on LoRa technology and mesh topology, where LoRa as a communication system is used to support a process of sending data between IoT devices, and mesh topology is used as a method of sending data between IoT devices. This study uses a mesh topology method in communicating or sending data which will function when one of the IoT devices is damaged or not functioning properly, the data transmission process will continue. When compared to other topologies, the mesh topology is a more efficient topology, because if a problem occurs such as damage to one of the IoT devices, the other devices will still be able to transmit data.

Research method is a basic aspect in the execution of a research. The research methodology contains the stages or descriptions of making research.

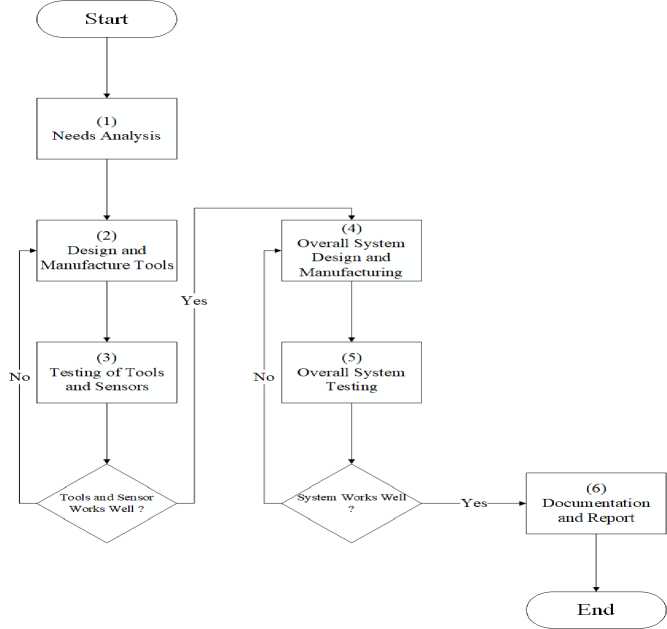

Figure 1. Research Method

Figure 1 can be interpreted as the stages of the research method used in making the research. The implementation of the research phase consists of six stages, namely needs analysis, tool design and manufacture, overall system design and manufacture, overall system testing, and system documentation that has been made in the form of reports. The following are detailed details of each stage of the research methodology.

First is needs analysis, this is an activity carried out to carry out the analysis needed and used to complete research. The analysis serves to get an overview of the research carried out, as well as theories relevant to the system to be made. Theories are sourced from journals, books, and datasheet documents. Second is design and manufacture of tools, is the stage where the hardware design process is carried out to support the work of the system to be made and then the manufacturing process is carried out. The design of the device and the manufacture of hardware aims to ensure that the hardware requirements needed are in accordance with the research to be carried out. Third is testing of tools and sensors, is the stage where the testing process of the tools that will be used to support the work of the system that will be made is carried out. Tool testing aims to find out how the performance of the tools and sensors is which if any malfunctions of the tools and sensors are found, the stages will return to the design and manufacture of the tools. Fourth is Overall System Design and Manufacturing, is the design stage of the system workflow that is made so that the workflow of the system to be made can be appropriate in order to solve problems in research in accordance with the research topic raised. After obtaining the system workflow design, the process of making a system consisting of various services and applications supporting the system is carried out with a programming language base that uses C, C++, PHP, and PL SQL. The last is Documentation and Report, are made at the end of the section after the overall system testing process is declared successful and can solve problems according to the topics raised. Reporting is intended to provide documentation of the results of the system that has been created and can be used by parties who need the report as a reference for system development or as research support material.

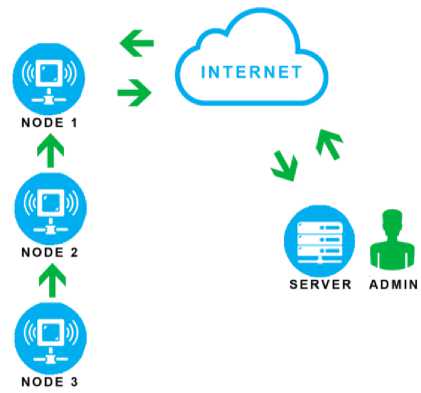

The development of a prototype data delivery system based on LoRa and mesh topology can be interpreted as a system that includes hardware and software that can lead to a system that can run manually or automatically and is more efficient. The admin can control the temperature centrally and precisely on the basis of the web application because the relationship between the sensor and the server coordinates or communicates with each other. An illustration of the development of a prototype data transmission system using the LoRa communication protocol by applying a mesh topology can be seen in the figure 2.

Figure 2. General Description System

Figure 2 can be interpreted as a general description of the system in which each sensor is interconnected and coordinated by the server. The server has a role to know the temperature of all sensors received, Then Admin can easily monitor the temperature of each sensor installed.

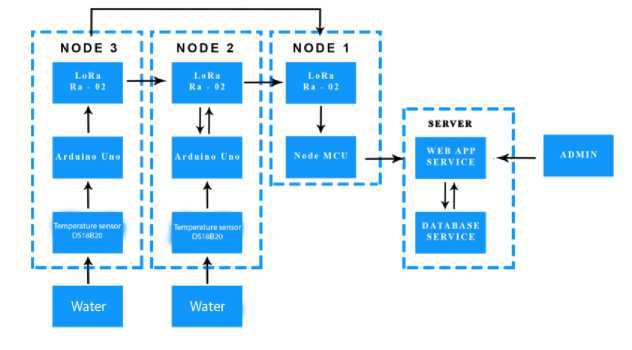

To clarify each component and service used to support the work process of developing a prototype data delivery system based on LoRa and mesh topology, this study needs a system block diagram. This can be illustrated using an image related to the block diagram which can be seen in the figure 3.

Figure 3. System Block Diagram

Figure 3 is a picture of a system block diagram, the picture above means that the tool block consists of a DS18B20 temperature sensor which has functions to read the water temperature. Then the microcontroller has the task of processing sensor data, both Arduino Uno and NodeMCU. In this case, LoRa serves as a communication bridge between devices. The first

tool communicates with the server using the NodeMCU device which serves as a communication bridge between the IoT devices and the server.

The Server block consists of various services that run such as a database service that serves as a temperature data store, then a web-based service that serves as a web application service provider as well as retrieves data from the NodeMCU and bring it into the database service.

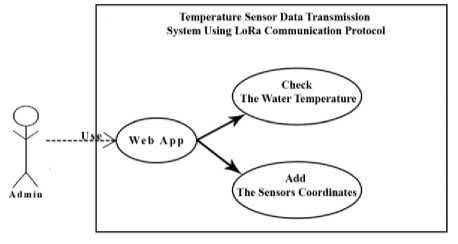

A model used in describing a system into several parts that can be arranged and represent a criterion of a system theoretically and efficiently to system observers is the definition of system modeling. There is a system modeling from the development of a prototype data delivery system based on LoRa and mesh topology using UseCase descriptions and Table Data Structures.

Figure 4. Use Case Sistem

The factor that plays a role in the system is admin, the admin factor gets the role to use the functionality provided by the system. The table data structure is shown in Table 1.

Table 1. Temperature Table Data Dictionary

|

No. |

Field Name Type Range Key Description |

|

1 2 3 4 5 |

Id_suhu Int 20 primary Temperature ID data_suhu varchar 255 Temperature data waktu timestamp Time koordinat_x varchar 255 Coordinates x koordinat_y varchar 255 Coordinates y |

Table 1. shows the data dictionary from the temperature table. The temperature table is used to store the obtained temperature data and also the data from the coordinates of each sensor.

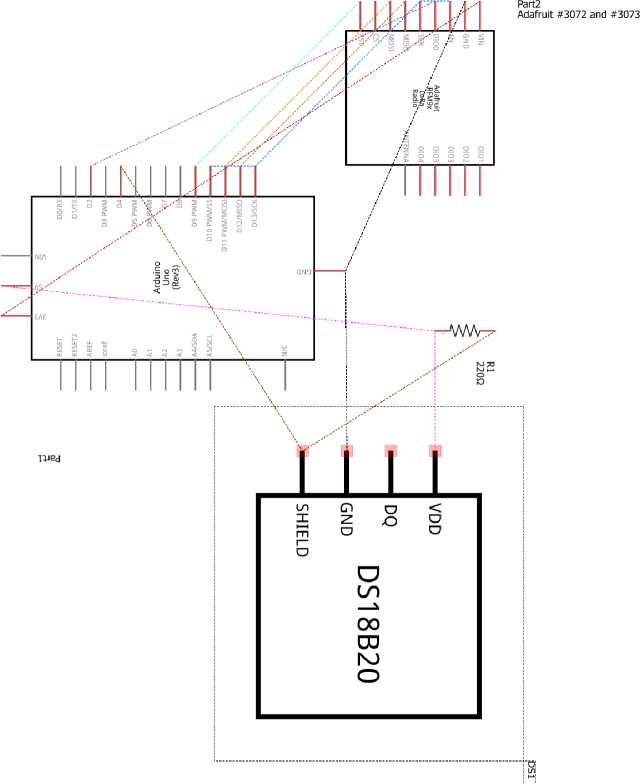

A schematic circuit is an electronic circuit that describes a series of electronic components with electronic symbols. The connection of each electronic component is depicted by connection lines in a circuit. The schematic series used in temperature measurement tools or IoT hardware in the development of a prototype data delivery system based on LoRa and mesh topology can be seen in the figure 5.

Figure 5. Schematic Circuit of Temperature Gauge

-

Figure 5 is a schematic diagram of a temperature measuring device, which consists of several displays that support its performance and are combined to form a single unit.

The ideas and concepts in this study come from literature reviews in the form of scientific journals, research reports, some books that related to this study.

Mesh topology is a network concept that cre a connection between devices that will be interconnected directly on a network. In a mesh topology, each device can only communicate with each other if they are in the same network, in general this topology is intentionally built on a network with a not too large scale, but requires communication between devices in a faster time [6]. Mesh topology is the most complex topology and is most often used by internet access service providers (ISPs / Internet Service Providers) because the Mesh Topology can keep damage or disturbances that occur on one computer will not affect other computers or the network as a whole [7].

Internet of Thing can be defined as a technology concept where each device can communicate or transfer the data without requiring any assistance or action from humans by simply going through communication media such as the internet or can be simplified to be like humans who no longer need to control the IoT device directly, but it is enough to control or remotely control IoT devices [8]. This is very useful for human life nowadays, where the users

can connect various tools such as machines or other objects, simply use a network and sensors to get the various data needed, resulting in the machine being able to obtain new information that is obtained independently just by applying Internet of Thing technology [8].

Various types of hardware and sensors that are integrated with each other has an important role in the development of the IoT system to create a unified IoT device system [9]. In general, IoT device systems use sensor devices to read and get information from an object. The information that has been obtained is then processed by a system that has been installed on the data processing device [8]. A computer or laptop can be used as a data processing device. The type used is the Arduino Uno type microcontroller and nodeMCU. Arduino Uno is used to processing data, while nodeMCU is used to connect IoT devices to the internet network.

LoRa is a new wireless communication technology. This communication technology can be used on objects that are deemed necessary to communicate with other objects. LoRa only requires low power sources such as batteries as the main supply to operate properly [10]. LoRa implementation on these objects is very easy because it does not require complex installation. This makes it easier for everyone who wants to create an IoT-based system [11].

LoRa network topology is generally in the form of star-of-stars, where the gateway acts as a bridge connecting LoRa IoT devices with the central network. The gateway is connected to the internet using an IP connection, while LoRa IoT devices communicate with each other using a single-hop wireless communication method. In general, LoRa IoT devices communicate in two directions, but if needed, these IoT devices can also broadcast to all nearby IoT devices. This capability allows the LoRa network to be configured according to the system requirements to be built [11].

The one used to support this study is LoRa Ra-02 with the Semtech SX1278 chip. Ra-02 is one of the LoRa devices created by AIThinker, with sensitivity values up to -148 dBm and power output up to +20 dBm and the maximum bandwidth that LoRa can get is around 5.5Kbps [12].

Database is a system designed to organize, store and get all the data needed easily at the same time. Sets of data that are organized for one or more uses in digital form are part of the Database [13]. Digital databases are organized using a Database Management System (DBMS), which can function as a repository of database contents, permitting the creation and maintenance of data as well as retrieval or other access. MySQL, SQL Server, Ms. Access, Oracle, and PostgreSQL are some of the existing databases, namely [14].

MySQL is a SQL database management system that is Open Source and the most famous in this era. MySQL database system also supports several features such as multithreaded, multiuser, and SQL database management system (DBMS). The purpose of this database is to make a database system that is fast, reliable and easy to use [15].

This section contains a discussion and analysis of the results describing the implementation of the system, testing the system and analyzing the level of success of the system whether the system can run properly or not.

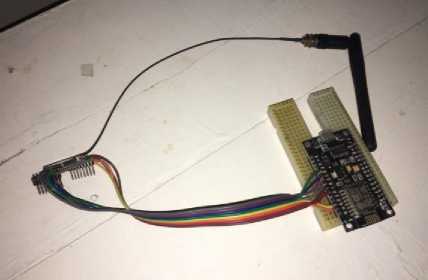

The realization of the design results from the development of a prototype data delivery system based on LoRa and mesh topology is shown in Figures 6 to 8.

Figure 6. Third IoT device

Figure 7. Second IoT device

Figure 8. First IoT device

Figure 6 to figure 8 are the hardware design realization from the development of a prototype data delivery system based on LoRa and mesh topology.

Tests in the data delivery system are carried out between the third IoT device, the second IoT device and the first IoT device. The IoT device reads the temperature conditions that exist in the system then is sent gradually from the third IoT device to the second IoT device and then received by the first IoT device and sends the data into the database server to be stored, so that admins can monitor the temperature on each IoT device. The table 2 shown the results of testing data transmission on IoT devices.

Table 2. The function of IoT devices

|

No |

Device |

Description |

Result |

|

1 |

Third IoT device |

The function is to check the temperature at the deployment location and send data to the second IoT device |

Succeed |

|

2 |

Second IoT device |

The function is to check the |

Succeed |

placement temperature, receive

temperature data from the third IoT device and then send the data to the first IoT

-

3 First IoT device The function is to receives the data Succeed

from the second IoT device and sends the data to the database

server

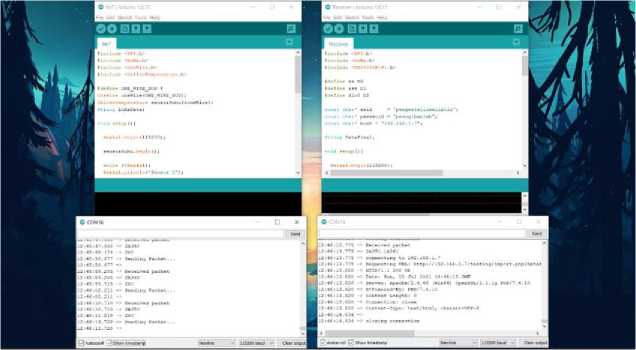

Tabel 2 is the result of testing every existing IoT device and successfully carrying out the process of sending data between IoT devices, each IoT device carrying out its respective functions to read the temperature value and send the temperature value to the IoT master device then proceed to delivery to the server. The figure 9 shown the results of testing data transmission on the third IoT device.

© COMU

I Send I

20:42:25.940 -> Sensor 1 a

20:42:27.445 -> 29

20:42:38.974 -> 29

20:42:50.518 -> 29

20:43:02.023 -> 29

20:43:13.530 -> 29

20:43:25.070 -> 30

20:43:36.581 -> 29

20:43:48.071 -> 30

20:43:59.580 -> 29

20:44:11.131 -> 30

20:44:22.626 -> 29

20:44:34.168 -> 29

20:44:45.689 -> 29 v

I I Autoscroll 0 Showtimestamp Newline ⅛∣ 115200 baud ^ Clearoutput

Figure 9. Results of Data Delivery on the Third IoT Device

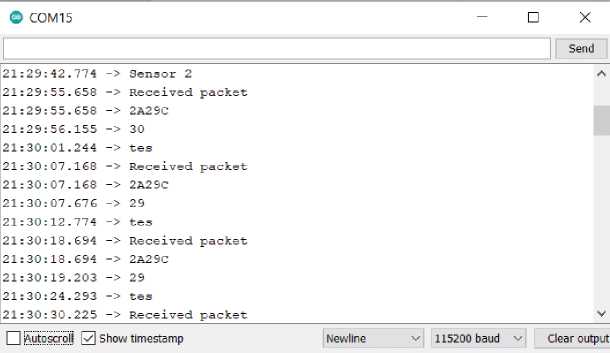

Figure 9 is the result of the command to check the temperature at the location of the tool and the process of sending data on the third IoT device. It is known that the data obtained is 29 degrees Celsius and then the data is sent again to the second IoT device. The figure 10 shown the results of testing data transmission on the second IoT.

Figure 10. The results of Data Delivery on Second IoT Device

Figure 10 is the result of the command to receive data from the third IoT device on the second IoT device, then the second IoT device also checks the temperature at the device location and continues the process of sending data on the first IoT device. It is known that the data obtained on the IoT device is worth 2A29C from the third IoT device and 29C from the second IoT device itself, then the data is sent to the first IoT device. The figure 11 shown the results of testing data delivery on the first IoT device.

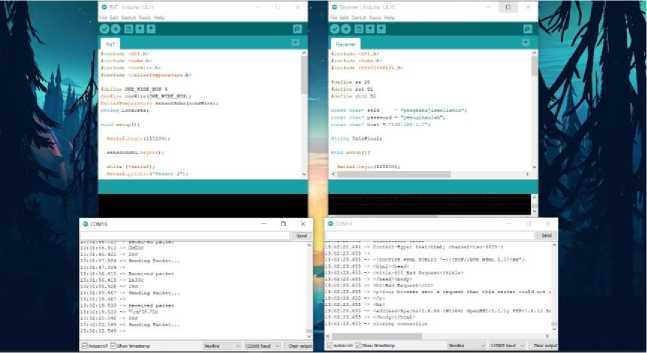

© C0M5

21:30:21.791 —> Received packet

21:30:21.791 -> 2A29C.1A29C

21:30:21.791 —> Requesting URL: http://192.168.1.7∕testing∕import.php?DataFinal=2A29C.1A29C

21:30:21.791 -> HTTP/1.1 200 OK

21:30:21.791 -> Date: Sun, 25 Apr 2021 13:30:21 GMT

21:30:21.791 —> Server: Apache/2.4.46 (Win64) OpenSSL/1.1.Ig PHP/7.4.10

21:30:21.837 -> X-Powered-By: PHP/7.4.10

21:30:21.837 —> Content-Length: 2

21:30:21.837 —> Connection: close

21:30:21.837 —> Content-Type: text/html; Charset=UTF-8

21:30:22.810 ->

21:30:22.810 -> yy

21:30:22.810 —> closing connection

Figure 11. The results of Receiving Data on the First IoT Device

Figure 11 is the result of the command to receive data on the first IoT device where the data is unified data from the third IoT device and the second IoT device which is sent and then received by the first IoT device. It is known that the data obtained is worth 2A29C.1A29C, then the data is sent to the database server device. The results of the signal strength in the process of sending data in RSSI calculations can be seen in the figure 12.

© COVIS

14:16:14.602 -> 28C

0 Autoscroll 0 Show timestamp

I Newline ^ j 1115200 baud ^ ∣ ∣ Clear output

Figure 12. RSSI Signal

Figure 12 shows the results of the signal strength obtained with values in the range -70dBm with a count of RSSI.

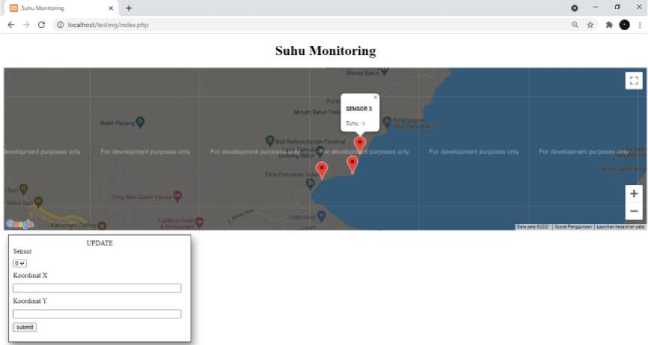

Implementation on the development of a prototype data delivery system based on LoRa and mesh topology. The following results from the implementation of the system can be seen in the figure 13.

Figure 13. Implementation Results

Figure 13 is the result of the implementation of the development of a prototype data delivery system based on LoRa and mesh topology.

Testing the tool with a given distance range and without being given an obstacle in sending data which aims to measure how far the tool is able to transmit data without an obstacle. The results of the study can be seen in the figure 14 to 15.

Figure 14. IoT Device Test Locations Without Obstacle

Figure 15. Tool Test Results With Distance Range and Without Obstacle

Figure 14 shows the location of the IoT device test with a distance of 250 meters shown by a yellow line, a distance of 500 meters is shown by a green line and a distance of 1 kilometer is shown in a red line and in Figure 15 shows the results that testing tools with a distance range given, namely 250 Meters, 500 Meters and 1 Kilo Meters were successfully carried out provided there were no obstacles that were passed during data transmission between IoT devices.

Testing the tool with a given distance range and given obstacles in sending data which aims to measure how far the tool is able to transmit data in the presence of obstacles in sending data. The results of the study can be seen in the figue 16 to 17.

Figure 16. IoT Device Test Locations With Obstacle

Figure 17. Tool Test Results With Distance And Obstacle Range

Figure 16 shows the results that testing the tool with a given distance range of 250 Meters, 500 Meters and 1 Kilo Meters by being given an obstacle every time you send data, where the results obtained only reach a maximum distance of 500 Meters if it exceeds that the delivery process fails as shown. shown in figure 17.

From the discussion and testing that has been done, there are four conclusions can be drawn. The first is the results of testing sensors with a distance range of 250 Meters, 500 Meters, and 1 Kilometers without many obstacles in the form of buildings or dense trees resulting in disturbances in sending data in the data transmission process, the results show that IoT devices run smoothly in the data transmission process. The second is the results of sensor testing with a distance range of 250 Meters, 500 Meters and 1 Kilo Meters with many obstacles in the form of buildings or dense trees resulting in disturbances in sending data, IoT devices are

only able to transmit data perfectly at a maximum distance of 500 Meters. The third is the results of the signal strength obtained from LoRa Ra-02 used in this study obtained an average of -70dBm with RSSI calculations. The fourth is the overall performance of the designed system is appropriate and running well based on testing every feature contained in the system, and the last conclusion is by implementing the development of a prototype data delivery system using the LoRa communication protocol by applying a mesh topology it can help in areas that are not covered by wifi or internet networks.

References

-

[1] Abdullah, 2019. Fenomena Digital Era Revolusi Industri 4.0. Jurnal Dimensi DKV,

-

Volume 4, pp. 47-58.

-

[2] Mirdanies, 2019. Data Transmission Method on a Room Condition. LONTAR

KOMPUTER, Volume 10, pp. 169-180.

-

[3] Wicaksono, 2019. Media Pembelajaran IoT Menggunakan ESP8266 Pada Mata Kuliah

Komunikasi Data Dan Interface, Yogyakarta: Lumbung Pustaka Universitas Negeri Yogyakarta.

-

[4] Bobby, 2021. Studi Kinerja Komunikasi Data Low Power Wide Area Network (LPWAN)

Menggunakan LoRaWAN Pada Daerah Hijau Universitas Andalas, Padang: Universitas Andalas.

-

[5] Triwidyastuti, 2019. Performance Analysis of Point-to-Point LoRa End. LONTAR

KOMPUTER, Volume 10, pp. 140-149.

-

[6] Eril, 2020. Pengertian Topologi Mesh Serta Kelebihan dan Kekurangannya. [Online]

Available at: https://qwords.com/blog/pengertian-topologimesh-serta-kelebihan-dan-

kekurangannya/ [Accessed 17 Mei 2021].

-

[7] Fabiokounang, 2017. Topologi Mesh pada Jaringan Komputer. [Online] Available at:

https://fabiokounang11.blogspot.com/2017/06/topologi-meshpada-jaringankomputer.html#:~:text=Topologi%20Mesh%20merupakan%2 0topologi%20yang,komputer%20lain%20atau%20jaringan% 20secara [Accessed 17 Mei 2021].

-

[8] Dharma, Piarsa & Suarjaya, 2018. Kontrol Kunci Pintu Rumah Menggunakan

Raspberry Pi. MERPATI, 6(3).

-

[9] Putra, Piarsa & Wibawa, 2018. Sistem Pendeteksi Kebakaran Menggunakan

Raspberry. MERPATI, Volume 6, pp. 167-173.

-

[10] Aswint Raj, 2019. Interfacing SX1278 (Ra-02) LoRa Module with Arduino. [Online] Available at: https://circuitdigest.com/microcontroller-projects/arduino-lora-sx1278-

interfacing-tutorial

-

[11] Aroeboesman, Ichsan & Primananda, 2019. Analisis Kinerja LoRa SX1278 Menggunakan Topologi Star Berdasarkan. Jurnal Pengembangan Teknologi Informasi dan Ilmu Komputer, Volume 3.

-

[12] Roberto, et al., 2021. Analisis Radio Transcaiver Pada Lampu Jalan Dengan Sistem

Modul RA-02, Pontianak: Roberto.

-

[13] Pursana, 2014 . Sistem Informasi Koperasi Modul Simpanan Berbasis. MERPATI,

-

Volume 2, pp. 67-78.

-

[14] Ramadhan & Mukhaiyar, 2020. Penggunaan Database Mysql dengan Interface. JTEIN:

-

Jurnal Teknik Elektro Indonesia, 1(2).

-

[15] Saputra, A., 2012. Manajemen Basis Data MySQL Pada Situs FTP, Bandung: Jurnal

Lapan.

T he Development of Prototype Data Delivery System Based on LoRa and Mesh Topology 58

(Dewa Gede Kesuma Yoga)

Discussion and feedback