The Development of Solar PV Car to Reduce Carbon Emissions from Transport Sector

on

Journal of Electrical, Electronics and Informatics, p-ISSN: 2549–8304 e-ISSN: 2622–0393

10

The Development of Solar PV Car to Reduce Carbon Emissions from the Transport Sector

M.F. Arieffadillah1, I.N.S. Kumara2, Y. Divayana3

-

1,2,3 Department of Electrical Engineering, Faculty of Engineering, Udayana University, Bali, Indonesia satya.kumara@unud.ac.id

Abstract – Global warming is contributed by human activities in many sectors. The sector that contributes significantly to generating carbon emissions is the transportation sector. An effort to reduce carbon emissions is by utilizing PV panels on the vehicle’s body surface. This paper reviews the development of vehicle-mounted PV panels around the world. The review covers technical specifications, manufacturer, and function of the PV panel on the vehicle. The objective is to get insight into the current development of vehicles with PV panels. The information presented in this paper is expected to provide updates for stakeholders in the field of renewable energy and land transportation in Indonesia. Also, this information can be used as a reference for further research on vehicles with PV panels both in Indonesia or elsewhere that are developing future environmentally-friendly vehicles. The result is a database consists of 948 vehicle which has solar PV around the body of the vehicle. 936 vehicles or about 99% were made for solar car race and only 1% for commercial and prototype. The solar PV system serves as a main or auxiliary power supply of the vehicle depending on whether they are hybrid or fully electric cars.

Index Terms – Emissions, Greenhouse Gases, Global Warming, Solar PV Roof, Vehicle Rooftop PV, Transportation.

Global warming is a phenomenon faced by people all over the world. This is a phenomenon where the sun's heat entering the earth cannot be reflected out because there is a layer of carbon gas blocking it. Collectively, this phenomenon is created by a variety of factors, the largest of which is carbon gas emissions. According to National Geographic, the level of carbon gas emissions in 2018 reached 411 ppm (parts per million), the highest monthly average emissions ever recorded of all time. Indonesia is ranked 10th out of the 20 biggest carbon-emitting countries worldwide [1].

Many solutions have been offered to fight global warming, one of which is the carbon tax. The carbon tax is a fee charged to the burning of carbon-based fuels to reduce and ultimately eliminate the use of fossil fuels that destroy the earth's climate. This has been implemented in various countries such as the UK, Canada, Australia, Sweden, and others and has produced results. In 2018, carbon emissions in the UK matched their emissions in 1890. Sweden applied a carbon tax since 1990, and from 1990 to 2005, emissions were reduced by 10.9 percent or 0.29 metric tons of CO2 per capita on average annually [2].

The Indonesian government has a target in reducing carbon emissions, one of which is to reduce the use of fossil fuels. In the 2015-2050 General Plan of National Energy or REUN, the government sets a reduction in the percentage of fossil energy from 82.5% in 2019 to 62.2% by 2050. This could be achieved through several policies, including reducing fossil energy exports gradually and achieving maximum use of renewable energy. Renewable

energies discussed in RUEN include geothermal, hydropower, mini-hydro and micro-hydro, bioenergy, solar power, wind, and also the currents, waves, and differences in sea layer temperature. The renewable energies that are now being intensively developed are the solar PV [3].

The solar power plant is usually installed on the ground with a ground mounting system or on the rooftop of buildings. However, other alternatives need to be developed considering that the ground mount system requires a large ground area hence a large sum of costs for land acquisition.

One alternative for solar PV applications is to utilize the body surface of the vehicle. Vehicles or transportation facilities are a potential sector for solar power development because according to data from the National Statistics Agency, in 2018 there were 146,858,759 vehicles in Indonesia. This large number of vehicles and their continuation to grow is in direct proportion to the need for large amounts of fuel, so the carbon emissions of conventional transportation are large and growing year by year.

Anticipating this phenomenon, many automotive companies have developed vehicles that utilize PV panels both as a vehicle propulsion power source and as an additional supply for the vehicle's electrical system to reduce emissions. For example, in South Korea, the automotive company Hyundai developed a vehicle called the Sonata Hybrid which has a solar panel on the roof that can charge the battery up to 60% if used 6 hours per day. This solar panel is claimed to have enough power to supply the car to run 1300 km a year [4]. Meanwhile, the

Netherlands has developed a vehicle known as Lightyear One which its roof and hood are equipped with PV panels. Lightyear One can charge the battery to a power equivalent to 570 km distance in 1 hour and also has a battery capacity that can cover a maximum distance of 725 kilometers [5].

This paper reviews the progress of the use of PV panels on vehicle surfaces around the world. The review covers the technical specifications, manufacturer, and function /utilization of the PV panel. Data is obtained through online surveys from vendor publications, manufacturers, scientific publications, and other online sources. The objective of the study is to obtain the current status of the development of vehicles with PV panels around the world. The information generated can be used as a reference for research on solar power as well as information for stakeholders of renewable energy and land transportation sectors in Indonesia.

Solar PV is a technology that utilizes the photovoltaic effect on semiconductors that converts sunlight into electrical energy. The photovoltaic effect is the ability of a material to release electrons when the material is exposed to light. The solar PV system mainly consists of 3 components, namely PV panels, charge controllers, and batteries. PV cells are the component to generate electricity from the sunlight. The combination of several PV cells forms a larger device called PV panels. The charger controller is a device to adjust the voltage or current when charging the battery to suit the specifications of the battery. This is necessary to optimize battery work and maximize battery life. Batteries are devices to store electrical power.

The application of solar PV systems in vehicles can be grouped into two. Solar PV systems that function as onboard charging systems, and solar PV systems which are used in hybrid vehicles. The two types of PV utilization are described in the following subsection.

A. Solar PV as On-Board Charging System

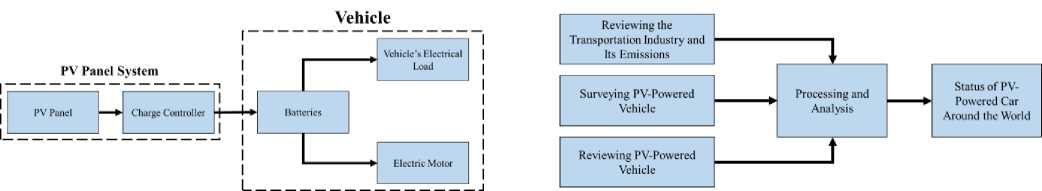

Figure 1 shows the schematic of Solar PV as an onboard charging system.

Fig. 1 Schematic Of The PV Panels As An On-Board Charging System

In system A, the solar PV is used as a backup/support of the power system in the vehicle. This system is used in electric vehicles or vehicles that as whole use electricity as the main driving force. In this system, the vehicle uses an electric motor that is supplied with power by batteries. The batteries can be charged using on-grid electricity and also utilizes the PV panel for charging.

B. Solar PV in Hybrid Vehicle

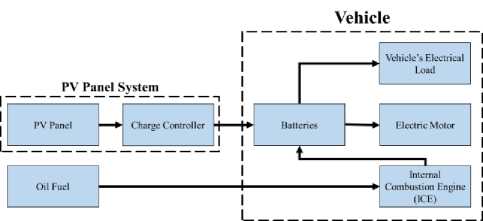

Figure 2 shows the schematic of the solar PV system in a hybrid vehicle.

In system B, the PV panel is used as a backup/ assistance of the power system in a vehicle. This system is

used in vehicles that use a hybrid system which means that it can use electricity or oil fuel as the main power source for driving force. In this system, the PV panel is used as an aid/backup for the charging system which can be used to support the electrical system as well as to drive the vehicle itself. In a hybrid system, the vehicle alternately uses a gasoline engine and an electric motor according to the user needs and availability of resources. On light vehicles work, such as when the engine is idling or at low speed, the vehicle will use an electric motor as a driving force, but on the heavy vehicle work such as driving at high speed, the vehicle will use a gasoline engine. Also, an electric motor can help when additional energy is needed, such as on an uphill road or overtaking [6]. This system is also expected to reduce the load on the engine, thereby reducing the use of fuel oil. In the long term, this system will help reduce the emissions generated by these vehicles.

Fig. 2 Schematic Of The PV Panel System In Hybrid Vehicle

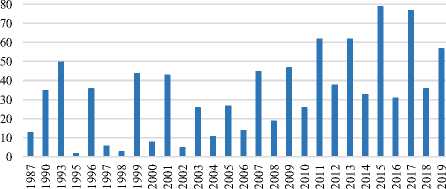

The data used in this paper includes the technical specifications for the vehicle and the onboard PV panel, the manufacturer, and the function/utilization of the PV panel. Data is obtained through manufacturer publications, scientific publications, and e-commerce pages around the world. Scientific publications are obtained using the Google Scholar search/ index engine, IEEE Xplorer, IndonesiaOneSearch, Academia, Mendeley, Researchgate, and others. For solar race vehicles, the data is obtained from the webpage of the solar car competitions. Figure 3 shows the general schematic of the workflow of the review.

Fig. 3 General Research Schematic

The first stage of the research is reviewing the status quo of the transportation industry and its emission. The data collected are then used to look at how a PV-powered vehicle can help to reduce carbon emission and how important it is for the future of environmentally-friendly vehicle technology. The next stage is surveying PV-powered vehicles around the world. In the stage, the research surveyed the development of PV-powered vehicles around the world. The vehicles surveyed are of various purposes, spanning from commercial, prototype to racing purposes. The next stage is reviewing the PV-powered vehicle. In this stage, the research looked at the

number of vehicles being developed each year, the manufacturer, the technology development, the components, and others based on the data that has been collected. The data will then be grouped according to several criteria to be analyzed. Later, the results of the analysis will show how the current status of PV-powered vehicles in the world, how the development trend is, and what can be concluded from this research. The analysis results obtained in this study are expected to be used as a reference for research on vehicle rooftop PV utilization.

This article attempts to review the development of vehicles with solar PV roofs around the world. By no means the review is exhaustive. Our survey of vehicles is developed into a database consist of 948 unit vehicles with solar PV roof developed by institutions around the world. The vehicles were produced in various models and by many countries. The database of vehicles that use solar power is arranged in a table containing the technical specifications of these vehicles. This database is available and can be obtained by contacting the author.

The data that has been collected is divided into several categories to see in detail how the technology development of vehicles with rooftop PV around the world. The discussion will be divided into 2, namely vehicles with rooftop PV panel which are produced commercially/prototypes and vehicles with rooftop PV which are produced for racing purposes (solar racecar).

-

A. Development of PV-Powered Car

The solar car race is a competition of vehicles with PV panel installed that is held at certain time intervals by assessing various aspects such as speed, endurance, energy consumption and production, and others. There are many solar car races in the world, the biggest and most famous is the World Solar Challenge. The World Solar Challenge was held every 2 years starting from 1987, where each team had to cover a distance of 3000 km from Darwin to Adelaide, Australia [9]. World Solar Challenge has 3 classes that can be followed by participants, namely Challenger, Cruiser, and Adventure with different objectives for each class. The Cruiser class focuses on the speed of the vehicle, the Challenger class focuses on the endurance, production, and energy consumption of the vehicle, while the Adventure class is more devoted to the development of PV-powered vehicles because vehicles in the previous series can be included in this class again, and this class does not compete. Apart from the World Solar Challenge, there are also several prestigious solar car competitions such as the American Solar Challenge, the Formula Sun Grand Prix, the South African Sasol Solar Challenge, and The Solar Car Challenge. These competitions are very influential on the development of PV technology in vehicles because in this competition there are quality standards that must be met and improved every year so that the researchers from various countries around the world are always looking for ways to improve the quality of the PV technology for their each of their vehicles. Table 1 shows the details of the competition above:

Table 1

Solar Car Race Around The World

|

No. |

Solar Car Race |

Starting Year |

Current Status |

|

1 |

World Solar |

1987 |

Active |

|

Challenge American Solar | |||

|

2 |

1990 |

Active | |

|

Challenge The Solar Car | |||

|

3 |

1995 |

Active | |

|

Challenge | |||

|

4 |

Formula Sun Grand |

2000 |

Active |

|

Prix | |||

|

5 |

South African Sasol |

2008 |

Active |

|

Solar Challenge |

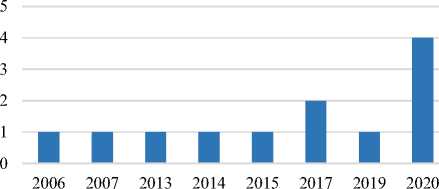

Figure 4 is a graph of the number of solar race cars in the world from 1987 (early development year) to 2019 obtained from the official website of the solar car competitions, namely the World Solar Challenge, American Solar Challenge, Formula Sun Grand Prix, South African Sasol Solar Challenge, and The Solar Car Challenge:

Number of Solar PV Roof Racing Car in the World

Fig. 4 Graph of the Number of PV-Powered Racing Car in the World

Figure 4 shows the development of PV-powered racing vehicles was fluctuating. From 1987 to 1999, the World Solar Challenge was held every 3 years but after that (1999 - 2019) it was held every 2 years. In the graph, it can be seen that during that time, the development of PV-powered vehicles in the year the World Solar Challenge was held was higher than in other years. The other races are held at varying intervals. Examples are The Solar Car Challenge which is held every year starting from 1995 and competitions that are held every 2 years such as the South African Sasol Solar Challenge from 2008, the American Solar Challenge from 1990, and the Formula Sun Grand Prix starting from 2000. But for the American Solar Challenge and the Formula Sun Grand Prix, the data collected starts from the year of 2010 [9] – [13].

The largest number of vehicles was in 2015 with a total of 79 vehicles, and the smallest number was 2 vehicles in 1995 with a total of 936 vehicles. The number of vehicles each year is influenced by the presence or absence of a solar car competition, especially the biggest race, the World Solar Challenge. As can be seen in the graph, the year in which the World Solar Challenge was held has a soaring trend compared to other years while other years, it is filled with other competitions such as the American Solar Challenge, the Formula Sun Grand Prix, and the South African Sasol Solar Challenge. The Solar Car Challenge competition always intersects with other competitions because it is held every year. Figure 5 shows

the development chart for PV-powered vehicles for commercial purposes and prototypes:

Number of PV-Powered Commercial and Prototype Car Around the World

Fig. 5 Number of PV-Powered Commercial and Prototype Car Around the World

Based on Figure 5, it can be seen that the development of PV-powered commercial and prototype cars is not so significant because the development of PV technology is still quite costly. The most rapid development occurred in 2020, where there were 4 vehicles with PV-panel being developed, namely Lightyear One made by Lightyear from Netherlands, Karma Revero GT Hybrid produced by Karma Automotive from the United States, 2020 Sonata HEV produced by Hyundai from South Korea, and The Sion made by Sono Motors from Germany. Whereas in the previous year, the development was quite stagnant with only 1 or 2 cars being developed per year and most of them were still in the prototype stage. The total number of vehicles recorded was 12 from 2006 to 2020. There are several examples of commercial cars that have been produced or are in the process of being developed. These vehicles are also designed not only to promote aesthetics but also to function properly. The vehicles are designed to look modern while also having a good aerodynamic level so that it also reduces the load when the vehicles are running. Some of the PV-powered vehicles produced in 2020 is shown in Figure 6.

Karma Revero GT

Lightyear One

The Sion

Fig. 6 PV-Powered Vehicles Developed in 2020

Hyundai Sonata Hybrid

Based on Figure 6, it can be seen that there are some similarities in the installation position of the PV panel. Karma Revero GT, Lightyear One, The Sion, and Hyundai Sonata Hybrid all have solar PV panels installed on top of their roof. The roof is the best place for PV panel installation because it is the highest part of the vehicle. It is intended to minimize shading and optimize the absorption of the sun on the vehicle. However, in some vehicles, the PV panel is not only installed on the roof. For

example, Lightyear One also has PV panels on the hood and The Sion has PV panels in almost all parts of its body surface such as the hood, doors, and other parts of the vehicle. The utilization of non-roof parts is intended to maximize solar energy capture.

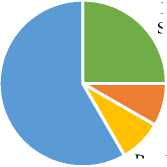

Figure 7 illustrates the distribution of PV-powered vehicles for racing purposes compared to commercial and prototype PV-powered vehicles. From 948 vehicles, 936 of them, or 99% are developed for racing purposes, while 12 vehicles or 1% are developed for commercial and prototype. The number of commercial vehicles and prototypes is far less than those for the race due to the design and development process of commercial cars that must meet various standards such as safety and emissions. Also, the costly development process will directly affect the selling price of the vehicle. This factor is important to take into account in the design to produce vehicles that are not only of good quality but also have a fairly affordable price.

Comparation between PV-Powered Cars for Racing Purposes and Commercial/Prototype Purposes

Racing Commercial /

99% Prototype

1%

Fig. 7 Graph of Comparison Between PV-Powered Cars for Racing Purposes and Commercial/Prototype Purposes

-

B. PV-Powered Vehicle Manufacturing Institution

PV-powered vehicles whether built for commercial, prototypes, or racing purposes are developed by various institutions around the world. Based on the data collected, educational institutions are the majority of institutions that develop PV-powered vehicles. Of the total 948 vehicles, 881 or 93% were made by educational institutions such as universities and high school. Figure 8 shows the comparison of PV-powered vehicle developers.

PV-Powered Vehicle Manufacturers Around the World

Educational

Institution 93%

Automotive Company 3%

Others

4%

Fig. 8 Graph of PV-Powered Vehicles

The reason for the domination of educational institutions as the largest contributor of PV-powered vehicles is perhaps because the majority of participants in all of the solar car races in the world are educational institutions. The United States also has The Solar Car Challenge, which is a special solar car race for high schools across America, so that more and more PV-powered

vehicles are produced. Educational institutions also contribute to the development of the prototype and commercial PV-powered vehicles, where 3 out of 12 vehicles, or 25% are produced by 2 educational institutions, namely Solar Mobil Manipal from India and Hochschule Bochum from Germany. Companies such as Honda, Kyocera, Nissan Motors, and others also participated in the solar car race in the early years of the World Solar Challenge, from 1987 to 1996.

For commercial and prototype PV-powered vehicles, automotive companies dominate the sector, where 8 of the 12 vehicles, or 67% are produced by 7 companies such as Venturi Automobiles from Monaco, Hitech Electric from Brazil, Squad Mobility and Lightyear from the Netherlands, Karma Automotives from the United States, and Hyundai from South Korea, as well as Sono Motors

from Germany. Table 2, shows the data of PV-powered vehicles for commercial and prototype purposes [4] [5] [14] – [21]. Some of the data in Table 2 is missing due to limited data in the public domains. This is probably due to the vehicles that are still under development, so the data has not been released publicly. Overall, automotive companies produced 29 of a total of 948 PV-powered vehicles worldwide or 3%. The third category in Figure 8, namely 'others', is vehicles produced by regional representatives, individuals, or non-profit organizations which produce 37 of the total 948 PV-powered vehicles worldwide or 4%. In the commercial vehicle department, this category only consists of 1 out of a total of 12 vehicles or 8%. This vehicle is called P-MOB Electric Cars and is produced by the European Commission consisting of researchers from Germany, Italy, Spain, and the UK [17].

|

Table 2 PV-Powered Vehicle For Commercial/Prototype | |

|

No. Vehicle Name |

PV PV Dimension Weight Passenger ICE ( mintrv Power ( .∩n∩cιtv Country Power Capacity (m) (kg) (people) (kW) (kWh) (cc) |

Karma Revero GT

|

Monaco 3,8 x 1,8 x 1,2 280 2 - - - Monaco - 390 3 - - - Europe - 600 2 - - - India - - 2 1 - - Germany - - 2 - - - Brazil 2 x 1,4 x 1,6 430 2 - - - India - - 4 1 - - Netherland 2 x 1 x 1,6 - 2 - - - United 5 x 2,1 x 1,3 2449 4 0,2 - 1500 States |

|

10 2020 Sonata HEV |

SKeolarteaan 4,9 x 1,8 x 1,4 1610 4 - - 1999 |

|

11 Lightyear One 12 The Sion |

Netherland 5 x 1,9 x 1,4 1300 5 - 6 - Germany 4,1 x 1,8 x 1,7 1400 6 - - - |

-

C. PV-Powered Vehicle Manufacturing Countries

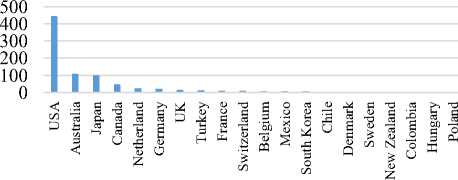

The technology of PV-powered vehicle for racing, commercial, and prototypes purposes are developed in all parts of the world. From the recorded data, 37 countries are participating in the development of PV-powered vehicles. The 37 countries that participate in the development of PV-powered vehicles are divided into 2 groups, namely countries that are members of the Organization for Economic Co-operation and Development (OECD) and outside the OECD. The OECD is an organization attended by 37 developed countries, which aims to become a forum for countries to stimulate trade as well as formulates policies that foster prosperity, equality, opportunity, and well-being for all [22]. Meanwhile, non-OECD is a country that is not part of the OECD organization by 2020. The separation into 2 groups aims to take a deeper look at the development of PV-powered vehicles in developed and developing countries because of their different growth rates. Figure 9 shows the development of PV-powered vehicles in countries that are members of the OECD.

Based on Figure 9, it can be seen that the United States is the largest contributor to the development of PV-powered vehicles. Of the total 948 vehicles to date, the United States produced 444 vehicles or 46.8%. This is because the United States has a lot of consistent solar car races every year. The United States has at least 3 large-

scale competitions, namely the American Solar Challenge, the Formula Sun Grand Prix, and The Solar Car Challenge. The target participants are also comprehensive and tiered, for example, The Solar Car Challenge is a special competition for participants from the high school level. Meanwhile, the Formula Sun Grand Prix is a competition to warm up and qualify for the American Solar Challenge the following year. The increasing number of competitions increases the sample number of the development of PV-powered vehicles so that the United States has a much higher number than other countries.

Number of PV-Powered Vehicles in OECD Countries

Fig. 9 Graph of PV-Powered Cars Development in OECD Countries

In the second place, there is Australia with a total of 109 vehicles or 11.5%. Australia is also one of the centers for the development of PV-powered vehicles and also hosts the world's largest solar car race, the World Solar Challenge. In third place, there is Japan with a total of 101 vehicles at 10.6%.

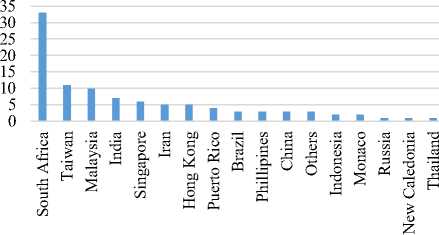

Meanwhile, there are also many PV-powered vehicles made by manufacturers/institutions outside the OECD participating countries. Figure 10 shows the development of PV-powered vehicles in non-OECD countries.

Based on Figure 10, it can be seen that South Africa is the country with the largest development of PV-powered cars in all non-OECD countries. This is because South Africa also organizes its solar car race, namely the South African Sasol Solar Challenge which has been held every 2 years since 2008. This competition is attended by academics from all over the world but from year to year, the majority of participants that take part in the South African Sasol Solar Challenge are educational institutions from South Africa itself. This factor directly impacts the rapid development of PV-powered vehicles in South Africa.

Number of PV-Powered Vehicles in NonOECD Countries

Fig. 10 Graph of PV-Powered Cars Development in Non-OECD

Countries

-

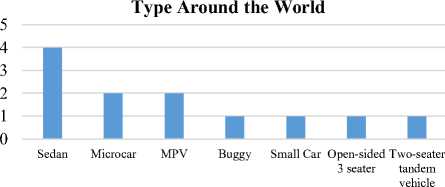

D. PV-Powered Vehicle Development Based on Vehicle’s

Types

Chapters D to H will focus only on the development of PV-powered vehicles and technology in prototype and commercial vehicles. The types of PV-powered vehicles being developed around the world are presented in Figure 11.

Commercial/Prototype PV-Powered Vehicle

Fig. 11 Graph of PV-Powered Vehicle Development Based on Vehicle Types

the already popular type around the world like sedans and MPVs. The microcar is the smallest type of car that uses 3 or 4 wheels with an engine below 700 cc capacity. A small/sub-compact car is a car that has a length of about 4 meters. The last 2 types in the graph are cars that are custom made as prototypes where the open-sided three-seater is a 3-seater car without doors and the two-seater tandem vehicle is a 2-seater car with a vertical passenger position.

Based on Figure 11, it can be seen that the majority of commercial vehicles and prototypes produced are sedans with a total of 4 out of 12 vehicles or 33% of the total sample. This is due to several advantages possessed by sedan type cars for the development of PV-powered vehicle technology, namely the sedan car has a light mass because it does not contain many passengers but on the other hand, it also has sufficient area to be used as a place for solar PV. For example, Lightyear One, from the Dutch brand Lightyear, uses not only the roof but also the hood with a total area of up to 5 m2. Also, the sedan type car has a more aerodynamic design so that it helps to lighten the load on the vehicle. Each type of microcar and multipurpose vehicle (MPV) has 2 vehicles that have been developed, while the buggy, small car, and prototype car types, such as open-sided three-seater and tandem 2-seater vehicles (two-seater tandem) each have 1 developed vehicle.

-

E. Prototype and Commercial PV-Powered Cars

Commercial vehicles are vehicles that are sold to the general public, while the prototype is made as a means of research and development. Data on the development of PV-powered vehicles based on these purposes of the vehicle is presented in Figure 12.

8

6

4

2

0

PV-Powered Car Purposes

Prototype

Commercial

Fig. 12 Graph of PV-Powered Vehicles Development Based on Vehicle Purposes

Based on Figure 12, it can be seen that both the prototype and commercial types of vehicles have the same number of 6 vehicles. All commercial vehicles were produced by the company, while 2 out of 6 prototype vehicles or 34% of the total prototype vehicles were made by educational institutions. This shows that to produce commercial vehicles requires a large amount of investment so that the commercialization of PV-powered vehicles can only be done by automotive companies. Apart from the large commercialization costs, the prototypes made by this educational institution are also an extension of the research and participation of each agency in the solar car race. These agencies are Solar Mobil Manipal from India and Hochschule Bochum from Germany.

There are several types of vehicles that are less commonly used by the public displayed in the graph beside

-

F. PV-Powered Vehicle Development Based on Batteries

The battery is an important component of a vehicle. The quality of energy storage is very dependent on the quality of the battery. Therefore, battery technology was developed intensively, in line with the development of electric vehicle technology itself.

From the vehicle data collected, it can be seen that the trend of battery capacity continues to increase from year to year. At the beginning of the development of PV-powered vehicles, in 2006 and 2007 Venturi Automobiles, a manufacturer from Monaco, released 2 vehicle variants, namely Venturi Astrolab and Venturi Eclectic, each of which has a battery capacity of 7 kWh. However, in the following years, developed vehicles always increased their battery capacity. For example, in 2017 SolarMobil Manipal from India released the SolarMobil Series-1 with a battery capacity of 19 kWh. In 2020, there are 3 different manufacturers, namely Karma Automotive, Lightyear, and Sono Motors, which released PV-powered vehicles. Karma Automotive Karma Revero GT has a capacity of 28 kWh, Sono Motors' the Sion has a capacity of 35 kWh and Lightyear's Lightyear One has the largest capacity of 60 kWh.

This increase in battery capacity was developed for several needs. The most important requirement is to increase battery autonomy. Battery autonomy is the length of time a battery can supply a certain load value. Greater battery autonomy means the durability of electric vehicles used will be better and longer. Also, a larger capacity is needed because the development of a vehicle also means the development of the features of the vehicle. The addition of features is certainly directly proportional to the increased energy needs as well. One example of a feature that supports the need for large battery capacity is The Sion's bidirectional charging feature from Sono Motors. This feature allows The Sion not only to take energy from a source but also to supply it out when needed. Figure 13 is a graph showing the types of batteries used in commercial and prototype PV mini-grid vehicles.

PV-Powered Car Batteries

Data not listed. 50%

Lithium Ion 50%

Fig. 13 Graph of PV-Powered Vehicle Batteries

Based on the type of battery used, 50% of all commercial and prototype PV-powered cars use lithium-ion batteries. Lithium-ion was chosen because it has many advantages, including a lighter battery than other batteries in the same capacity class, high energy density, and a fairly long lifecycle (500 - 1000 cycles) [23] [24].

-

G. PV-Powered Vehicle Development Based on Electric

Motors

In an electric vehicle, the motor is the main driver of the vehicle. Therefore, the electric motor is a component

that continues to be developed and optimized for its use. This trend is also evident in the development of commercial and prototype PV-powered vehicles. Figure 14 is a graph depicting the types of electric motors used in PV-powered vehicles.

From the data collected, it can be seen that the motor development in the PV-powered vehicle is moving towards the use of synchronous motors with permanent magnets. This use of permanent magnets is because the motors with permanent magnets will cost less in maintenance. After all, there is no need for regular replacement of motor brushes. The absence of brushes on the motor also increases the work efficiency of the motor due to the reduction in losses of commutation brushes.

PV-Powered Car Electric Motors

Data not listed 59%

Asynchronous Motor 8%

Permanent Magnet Synchronous Motor 25%

Fig. 14 Graph of PV-Powered Vehicle Electric Motors

Brushed DC Motor

8%

Synchronous motors are chosen because of several advantages. One of the advantages of synchronous motors is that the motor can work at a constant speed even though the load changes [25]. This is necessary for vehicle design because the vehicle must maintain its quality of work even though it is used on different road conditions. Also, according to the study, when synchronous motors are compared to other types of motors (synchronous reluctant motors), synchronous motors have better efficiency. With the same load value, the current value to the active power required by asynchronous motor is smaller so that less energy is needed.

Many of the PV-powered vehicles being developed also use regenerative braking. Regenerative braking allows a motor to act temporarily as a generator during braking so that energy is not wasted in the form of heat but is flowed back to the power supply. This feature minimizes energy losses so that energy is used more efficiently and extends battery life as a power supply.

-

H. PV-Powered Vehicle Development Based on PV Panels

The use of PV panels in commercial electric vehicles is a relatively new technology so that not many manufacturers have developed vehicles with this technology. Figure 15 is a graph depicting the types of PV modules used in PV-powered vehicles.

PV-Powered Cars PV Modules

Data not listed 25%

Polycrystalline 17%

Monocrystalline 58%

Fig. 15 Graph of PV-Powered Vehicle PV Modules

Referring to the collected data, the majority of PV-powered vehicles are designed using solar panels made from monocrystalline silicon. Monocrystalline silicon solar panels are solar panels that are made using one type of silicon crystal. This type of solar panel is higher in price than other types of panels, but monocrystalline panels are used because they have the highest level of efficiency compared to other types. This is due to the single silicon crystals on the monocrystalline panel. In theory, for this high efficiency, the electrons would have to move freely as in pure silicon. Monocrystalline is a derivative of pure silicon that is melted and re-crystallized to be made into more affordable PV-grade silicon but with the highest efficiency levels of 16-17% [26].

This level of efficiency has also been proven in several studies, one of which was carried out by Aysegül Tasçioglu et al in 2016, where the study compared energy generation between monocrystalline and polycrystalline PV panels in Bursa Province, Turkey. As a result, monocrystalline recorded an average daily efficiency value of 6.65% compared to 5.38% efficiency of polycrystalline. High efficiency is needed in the design of a PV-powered vehicle, considering that the limited area of the vehicle that can be installed with PV panels. Table 3 shows the data table on the area of vehicles rooftop PV panel and the vehicle dimensions.

Table 3

Area Of PV Panel

|

Name |

Dimension (m) |

Area of PV Panel (m2) |

|

2020 Sonata HEV |

4,9 x 1,8 x 1,4 |

2,8 |

|

Lightyear One |

5 x 1,9 x 1,4 |

5 |

|

The Sion |

4,1 x 1,8 x 1,7 |

7,5 |

The area of PV panels used in each commercial PV-powered vehicle and prototype is also different, however, the more modern the vehicle is, the more extensive the manufacturer will develop the PV panel. For example, The Sion owned by Sono Motors has PV panels that are spread all over the body of the vehicle with a total area of up to 7.5 m2. In ideal weather, The Sion is claimed to be able to generate 1.2 kW of energy in a day or equivalent to the energy for a distance of 34 km [15]. Lightyear One owned by Lightyear has PV panels installed on the roof and hood of the vehicle with a total area of 5 m2. In optimal conditions, the solar PV is claimed to be able to generate energy to travel 15 km in 1 hour [5]. Seeing this trend, the direction of developing PV panels in the future is how to optimize the area of the existing PV panels as well as finding ways to design how this area can be increased

without reducing the performance and aesthetics of the vehicle because the more optimal use of PV panels in vehicles, the closer the world is to environmentally friendly vehicles with performance as good as or even better than conventional vehicles.

-

I. PV-Powered Vehicle Development Based on Vehicle Prices

The more advanced the development of technology, including the PV-powered vehicle, the more competitive the price will be in the development process. In Table 4, the commercially released PV-powered vehicle price data has been compiled. This data is taken from the websites and publications of each manufacturer. Table 4 shows the price data for commercial PV-powered vehicles in tabular form.

Based on Table 3, it can be seen that the price of commercial PV-powered vehicles is quite high. This is due to the development of electric vehicle technology which is still relatively high in price. Lightyear One is the vehicle with the highest price because this vehicle has various features with a long research process (from 2016). The Lightyear One feature is driving with 4 individual motors on each wheel to minimize engine loss, PV panels which are claimed to increase the mileage by 12 km/hour, the fast-charging process which is claimed to be able to charge energy for a distance of 570 km in one hour, and others. While the vehicle with the lowest price is the Squad Solar City Car, which is a microcar with a capacity of only 2 people. This low price is due to the lack of features and capabilities of the vehicle that are not like the class of vehicles above it.

Table 4

PV-Powered Vehicle Prices

|

Name |

Prices (USD) |

|

Karma Revero GT Hybrid |

146.600 |

|

2020 Sonata HEV |

27.750 |

|

Lightyear One |

170.000 |

|

The Sion |

25.500 |

|

e.CoTech 2 |

14.404 |

|

Squad Solar City Car |

5506 |

-

J. Solar PV Car Effects on Carbon Emission

The contribution of the electric car to carbon emission is caused by the fact that it does not consume oil-based fuel, hence no tailpipe emissions. It can be seen that in Indonesia exclusively, the transportation sector contributes to high greenhouse gas emissions with a total of 28% of the total emissions produced [7]. From the total transportation emission value, as much as 85% was emitted by vehicles on the road [8]. This is due to the increase in the number of motorized vehicle ownership from year to year without being followed by a shift to vehicles that are more environmentally friendly and one of the efforts that need to be taken to reduce these emissions is to develop electric transportation modes. In this subsection, the article would attempt to hypothetically calculate how much carbon emission can be reduced by switching into electric cars. The article would calculate the emission with the assumption of the car with the best fuel economy. As of 2020, the non-hybrid car with the best fuel economy is the Mitsubishi Mirage with 16,5 km/l of gasoline [27]. Energy consumption can be calculated with Formula 1 [28].

EC1 = EC2 × Heating Value (1)

Energy consumption (EC1) is stated in Terra Joule (TJ), energy consumption (EC2) is stated in liter and heating value is stated in TJ/l. On annual average people drive as far as 21687 km [29]. Gasoline’s heating value is 33×10-6 TJ/l [28] and its emission factor is 72.600 kg/TJ [30]. With that information, we can calculate the energy consumption with Formula 1.

EC1 = 1314 × 33 × 10-6 EC1 = 0,043 TJ

Mathematically, carbon emission can be calculated with Formula 2 [28].

Emission = Energy Consumption × Emission Factor (2)

Emission is stated in kg/year, energy consumption is stated in TJ/year and emission factor is stated in kg/TJ. So, the total emission produced by one Mitsubishi Mirage a year can be calculated with Formula 2.

Emission = 0,043 × 72600 Emission = 3.121 kg/year

With an electric car, the amount of emissions can be reduced or completely removed if charged from renewable sources. But the power is sourced from the grid. With the addition of solar PV, the amount of energy generated while driving under the sun will offset energy taken from the grid for EV or reduce the fuel for the hybrid vehicle. Lightyear claims that Lightyear One’s solar PV can generate power equivalent to 133 days of driving if the car is being driven for 20.000 km a year. This is achievable because of the 5 m2 solar PV installed in Lightyear One can generate power equivalent to 15 km for an hour under the sun [5]. The Sion from Sono Motors claims that their 7,5 m2 solar PV can generate power as much as 34 km a day or 5.800 km a year [15]. Figure 16 shows the comparison of carbon emission between conventional, hybrid, and electric cars. The cars used in the comparison are the cars with the best fuel economy from each type of car.

Carbon Emission Level

4000

3000

2000

1000

0

Conventional Hybrid (Toyota Electric Vehicle

(Mitsubishi Corolla Hybrid) (The Sion)

Mirage)

Fig. 16 Comparison of Carbon Emission Level Between Conventional, Hybrid and Electric Cars

Based on Figure 16, it can be seen electrical power, both in hybrid and electrical vehicle, reduce the carbon emission significantly. The conventional car is the Mitsubishi Mirage with a fuel economy of 16,5 km/l, the hybrid car is the Toyota Corolla Hybrid with a fuel economy of 22 km/l [36] while the electric vehicle is The Sion. Using equations 1 and 2, Mitsubishi Mirage produces 3121 kg/year of emission, while Toyota Corolla Hybrid produces 2351 kg/year of emission. The Sion produces zero tailpipe emission because it requires only electricity as a power source. While producing zero-emission, PV-

powered vehicles can generate power from its on-board solar PV system hence reducing grid charging.

K. The Benefit of Vehicle Rooftop PV Panel

Based on the discussion above, there are several benefits of using PV panels in electric or hybrid vehicles, including:

-

1) As an environmentally friendly and renewable energy source. With the installation of PV panels, the transportation sector, which is one of the largest emitters, can reduce emissions from the use of fuel oil.

-

2) As a source of free energy to reduce fuel use. The PV panel technology in vehicles allows the vehicle to run without having to be charged using on-grid electricity and only utilizing the sun which can be used at no cost. PV panels also do not require oil changes/other fuel products so that they can also contribute to reducing fuel consumption.

-

3) As a cost saver. With the installation of solar PV, electricity costs needed for the charging process from on-grid electricity can be reduced. The cost required for the maintenance of PV panels is also relatively small.

-

4) As a source of energy that can be obtained anywhere. By installing a PV panel on the vehicle, the vehicle can get energy anywhere as long as the vehicle is exposed to the sun apart from the on-grid electricity.

L. PV-Powered Vehicle in Indonesia

Indonesia has abundant solar resources. According to RUEN, Indonesia as a whole has the potential for solar resources reaching 4.8 kWh/m²/day or equivalent to 112 thousand GWp. Until now, the utilization is still very small compared to its enormous potential, whereas of 2020 the accumulative installed capacity is only 152.44 MWp [31]. This utilization is still small considering that Indonesia is a country that is exposed by sunlight throughout the year. With that enormous potential, further, development is needed regarding its utilization, one of which is through the transportation sector.

Indonesia has participated in the development of PV-powered cars. Indonesia through the Sepuluh Nopember Institute of Technology Surabaya sent two representatives to the 2013 and 2015 World Solar Challenge, by sending vehicles known as Sapu Angin Surya (SA-S) and Widya Wahana V (WW-V). Sapu Angin Surya was sent as a representative for the challenger class which focuses on speed and managed to cover a distance of up to 748 km [32]. Widya Wahana V was sent as a representative in the cruiser class that focuses on endurance and energy production and was ranked 10 [33]. Figure 17 shows pictures of Sapu Angin Surya (SA-S) and Widya Wahana V (WW-V):

Sapu Angin Surya (SA-S)

Fig. 17 PV-Powered Car Produced by ITS

Widya Wahana V (WW-V)

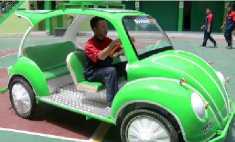

Apart from universities, enthusiasm for PV-powered vehicles was also shown by people from various backgrounds. For example, at SMK Ma'Arif 1 Wates, Kulon Progo, Yogyakarta Special Region, there are cars with PV panels that have been developed by students from several disciplines. The car has 1 solar module with a charging process that takes 16 hours to use enough for 4.5 hours [34]. Also, in Banyumas, Central Java, students from SMK 1 Ma'Arif NU 1 Sampiuh developed a car with a PV panel called Molisma. This car can go up to 25 km at a speed of 30-40 km/hour with the charging process using a PV panel which takes 7 hours [35]. Figure 18 shows the pictures of the electric cars produced by the said SMK:

SMK Ma’Arif 1 Electric Car

Fig. 18 PV-Powered Car Produced by SMK

Molisma

In the future, the research and development need to be stimulated so that in the field of electric vehicles and especially in the context of implementing renewable energy can be better and more sustainable. With the enthusiasm that comes from various backgrounds and support from stakeholders, Indonesia could work together to pursue the application of PV technology and electric vehicles. From the discussion above, it can be seen that the development of PV-powered vehicles in the world is largely due to competition, so to accelerate the development of PV-powered vehicles in Indonesia or in countries interested in developing PV-powered vehicles, it is necessary to hold competitions related to PV-powered cars within educational institutions, industry, and the general public.

This paper has reviewed the development of solar power plant applications in vehicles/land transportation. Statistically, it was found that PV-powered vehicles were still few in number and the existing models were dominated by race vehicles. However, since the last few years, prototypes for passenger cars have been developed. In terms of body design, this PV-powered passenger car is no different from a conventional car with the advantage of being more environmentally friendly. These vehicles continue to be developed so they can be produced with good performance similar to a conventional vehicle or higher.

References

-

[1] National Geographic. (2019). Carbon Dioxide Levels Are at a Record High. Here's What You Need To Know. Retrieved 17 March 2020, from

https://www.nationalgeographic.com/environment/global-warming/greenhouse-gases/.

-

[2] Julyus J. Andersson. (2019). Carbon Taxes and CO2 Emissions: Sweden as a Case Study. American Economic Journal: Economic Policy 2019, 11(4): 1–30 https://doi.org/10.1257/pol.20170144.

-

[3] Kementerian Energi dan Sumber Daya Mineral Republik Indonesia. (2015). Dokumen Rencana Strategis Kementerian Energi Dan Sumber Daya Mineral Tahun 2015 – 2019. ESDM.

-

[4] Hyundai. (2019). 2020 Sonata Hybrid. Retrieved 17 March 2020, from https://www.hyundaiusa.com/us/en/vehicles/sonata-hybrid.

-

[5] Lightyear. (2019). Lightyear One. Retrieved 17 March 2020, from

https://lightyear.one/lightyear-one/.

-

[6] The United States Environmental Protection Agency. (2016). How do Hybrids Work? Retrieved 23 March 2020, from https://www.fueleconomy.gov/feg/hybridtech.shtml.

-

[7] Climate Transparency. (2019). Brown to Green 2019: Indonesia Country Profile (pp. 1–20). Climate Transparency. https://www.climatetransparency.org/wpcontent/uploads/2019/11/ B2G_2019Indonesia.pdf

-

[8] Setiawan, I., Indarto, I., & Aan, D. (2019). Reducing CO2

Emissions from Land Transport Sector in Indonesia: Case Study Automobiles Sector. Journal of Physics: Conference Series, 1167, 012008. https://doi.org/10.1088/1742-6596/1167/1/012008.

-

[9] World Solar Challenge. (1987 – 2019). Past Winners. Retrieved 17 July 2020, from https://www.worldsolarchallenge.org/.

-

[10] American Solar Challenge. (1990 – 2018). Past Winners. Retrieved 17 July 2020, from https://www.americansolarchallenge.org/.

-

[11] Formula Sun Grand Prix. (2000 – 2019). Past Winners. Retrieved 17 July 2020, from https://www.americansolarchallenge.org/.

-

[12] South Africa Sasol Solar Challenge (2008 – 2018). Past Winners. Retrieved 17 July 2020, from https://www.solarchallenge.org.za/.

-

[13] Solar Car Challenge. (1995 – 2019). Past Winners. Retrieved 17 July 2020, from https://www.solarcarchallenge.org/challenge/

-

[14] Karma Automotives (2019). Karma Revero GT. Retrieved 17 March 2020, https://www.karmaautomotive.com/reverogt.

-

[15] Sono Motors (2019). The Sion. Retrieved 17 March 2020, from https://sonomotors.com/en/sion/.

-

[16] Venturi Automotive. (2006). Concept Car. Retrieved 17 March 2020, from https://www.venturi.com/en/concept-car /

-

[17] New Atlas. (2013). P-MOB Electric Car Travels 20 Km on Solar Power Alone. Retrieved 17 March 2020, from https://newatlas.com/p-mob-solar-electric-car/28691/.

-

[18] Solar Mobil Manipal. (2011). Completed Projects. Retrieved 17 March 2020, from https://www.solarmobilmanipal.in/.

-

[19] Hochschule Bochum. (2015). SolarBuggy OpenWorld. Retrieved 17 March 2020 http://solarbuggy.hs-bochum.de/historie/open-world/

-

[20] Hitech Electric. (2017). e.coTech Datasheet. Hitech Electric.

-

[21] Squad Mobility. (2019). Squad Solar Car. Retrieved 17 July 2020, from https://squadmobility.com/

-

[22] The Organization for Economic Co-operation and Development (OECD). Who We are. Retrieved 17 July 2020, from http://www.oecd.org/about/.

-

[23] Muhammad Thowil Afif, Ilham Ayu Putri Pratiwi. (2015). Analisis Perbandingan Baterai Lithium-Ion, Lithium-Polymer, Lead Acid dan Nickel-Metal Hydride pada Penggunaan Mobil Listrik – Review. Jurnal Rekayasa Mesin Vol.6, No.2 Tahun 2015: 95-99 ISSN 2477-6041.

-

[24] Elizabeth Putri Permatasari, Mega Permata Rindi, Agus Purwanto. (2017). Pembuatan Katoda Baterai Lithium Ion Iron Phospate (LiFePO4) dengan Metode Solid State Reaction. EQUILIBRIUM Volume 16 No.1 Januari 2017 Online at

http://equilibrium.ft.uns.ac.id.

-

[25] Bambang Sugiyantoro, F. Danang Wijaya, Fajar Wijayanto. (2015). Perbandingan Unjuk Kerja Motor Reluktan Sinkron dan Motor Sinkron. Departemen Teknik Elektro dan Teknologi Informasi, FT UGM. ISSN: 2085-6350 Yogyakarta, 15 September 2015 CITEE 2015.

-

[26] Steven Hegedus, Antonio Luque. (2011). Achievements and Challenges of Solar Electricity from Photovoltaics. Wiley.

-

[27] Cars and Drivers. (2019). 10 Non-Hybrid, Non-Electric Cars with the Highest MPG in 2019 - 2020. Retrieved on 30 August 2020, from https://www.caranddriver.com/features/g15382442/best-gas-mileage-nonhybrid-cars-gasoline-nonelectric/?slide=19.

-

[28] Kementerian Lingkungan Hidup. (2012). Metodologi Penghitungan Tingkat Emisi Gas Rumah Kaca. KLHK.

-

[29] Federal Highway Administration. (2018). Average Annual Miles per Driver. Retrieved on 30 August 2020, from https://www.fhwa.dot.gov/ohim/onh00/bar8.htm.

-

[30] Kementerian Energi dan Sumber Daya Mineral Republik Indonesia. (2017). Kajian Penggunaan Faktor Emisi Lokal (Tier 2) dalam Inventarisasi GRK Sektor Energi. Jakarta: Pusat Data dan Teknologi Informasi ESDM. ESDM.

-

[31] Kementerian Energi dan Sumber Daya Mineral Republik Indonesia. (2020). Menengok Ladang Panel Surya Terbesar di Indonesia. Retrieved at 20 August 2020, from

http://ebtke.esdm.go.id/post/2020/03/13/2508/menengok.ladang.pa nel.surya.terbesar.di.indonesia#:~:text=%22Seluruh%20Indonesia %2C%20kapasitas%20terpasang%20mencapai,sisanya%20PLTS %20on%20the%20ground..

-

[32] Tempo. (2013). Sapu Angin Surya Menjajal Gurun Australia. Retrieved 19 August 2020, from https://koran.tempo.co/read/ilmu-dan-teknologi/325539/sapu-angin-surya-menjajal-gurun-australia?.

-

[33] Institut Teknologi Sepuluh Nopember. (2015). Widaya Wahana V. Retrieved 19 August 2020, from http://sko.its.ac.id/widya-wahana-v/.

-

[34] Radar Jogja. (2019). SMK Ma’arif Wates 1 Ciptakan Mobil Listrik Tenaga Surya. Retrieved at 22 August 2020, from https://radarjogja.jawapos.com/2019/12/13/smk-maarif-temon-1-ciptakan-mobil-listrik-tenaga-surya/.

-

[35] Kompas. (2019). Siswa SMK di Banyumas Ciptakan Mobil Listrik Tenaga Surya, Melaju hingga 40 Km Per Jam. Retrieved at 22, August 2020, from

https://regional.kompas.com/read/2019/09/03/06553391/siswa-smk-di-banyumas-ciptakan-mobil-listrik-tenaga-surya-melaju-hingga-40?page=all.

-

[36] The United States Environmental Protection Agency. (2020). Most Efficient Cars by EPA Size Class (Excluding Electric Vehicles). Retrieved 02 September 2020, from

Discussion and feedback