IoT-Based Machida Cultivation Method Implementation in Hydroponic System to Increase Melon Crop Productivity

on

Journal of Electrical, Electronics and Informatics, p-ISSN:2549-8304 e-ISSN:2622-0393

9

IoT-Based Machida Cultivation Method Implementation in Hydroponic System to Increase Melon Crop Productivity

Guntur Petrus Boy Knight1, Istas Pratomo Manalu2, and Sari Muthia Silalahi3

1Program Studi Teknik Elektro Institut Teknologi Del Kabupaten Toba, Sumatera Utara guntur.siboro@del.ac.id 2,3Program Studi Teknologi Komputer Institut Teknologi Del Kabupaten Toba, Sumatera Utara istas.manalu@del.ac.id, sari.silalahi@del.ac.id

Abstract National consumption of fruits in Indonesia is expected to increase. The reasons for this are the awareness of Indonesian about the health effect of fruits consumption and the demographic bonus that will increase Indonesian economic output which in turn increase the consumption of fruits in the long run. Without the increase in fruits production, the price of fruits will increase as a consequence of supply and demand imbalance. In this research we tried to increase the productivity of Melon crops as a study case. Traditional cultivation of melon usually produces 1-2 melons per crop. The purpose of this research is to increase the productivity of Melon crops to at least 8 melons per crop using method such as IoT, Hydroponic system, and Greenhouse. Despite several drawbacks from the initial research design, the result of the research successfully increased the productivity of melon crop as stated in the research purpose.

Index Terms— Greenhouse, Hydroponic, IoT, Machida Cultivation Method, Melon Crop, Raspberry Pi.

In the near future, fruits consumption in Indonesia will increase. There are 2 main reasons for this, the first reason is due to increased awareness among Indonesian about the health effect of food consumptions. The second reason is due to demographic bonus that our country will get, which in turn will increase the economic output of Indonesia. Without the increase in fruits production, the price of fruits will increase because of supply and demand imbalance. This can be prevented if the fruits production also increases to match the increase demand of fruits. One way to increase fruits production is to increase the crops productivity.

This research will use Melon as study case. Conventional Melon cultivation productivity is 1-3 melon per crops. This research aims to increase the productivity to at least 8 melons per crops.

This document is a template for Microsoft Word versions 6.0 or later. If you are reading a paper or PDF version of

this document, please download the electronic file from the Open Journal System (OJS) the Institute for Research and Community Services Udayana University (IRCS UNUD) Journal Website at ojs.unud.ac.id so you can use it to prepare your manuscript.

When you open the template, select “Page Layout” from the “View” menu in the menu bar

which allows you to see the footnotes. Then, type over sections of the template or cut and paste from another document. Do not change the font sizes or line spacing to squeeze more text into a limited number of pages. Use italics for emphasis; do not underline. To insert images in Word, position the cursor at the insertion point and either use Insert | Picture | From File or copy the image to the Windows clipboard and then Edit | Paste Special | Picture (with “float over text” unchecked).

A. Melon

Melon is categorized as a high nutritious fruits. It

contains 78 calorie, 28 mg natrium, 593 mg kalium, 4 mg calcium, 10 mg iron, 25 gr carbohydrate, 2 gr fiber, 21 gr sugar, and 90 mg vitamin C. It also contain anticoagulant (adenosine) that stops blood cells coagulation which caused stroke and heart disease [1]

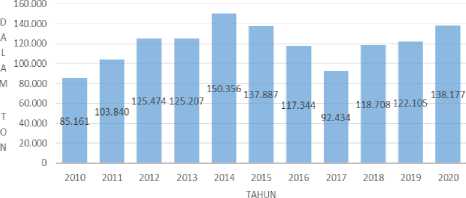

PRODUKSI BUAH MELON NASIONAL

-

Figure 1. Annual Production of Melon in Indonesia

As a commodity, melon attracts comparably high attention in Indonesia [2]. National production of melon crops can be seen in Figure 1. This figure shows that melon production has fluctuated. Peak production happened in 2014, and then drop annually until started to rise again from 2017 to 2020 [3]. Melon is not native to Indonesia, nevertheless it will produce fruit as long as the environment is conducive [4]. The conditions for melon cultivation are:

-

1. It needs 10-12 hour sunshine daily.

-

2. The environment temperature for it is 16-30 Celsius.

-

3. The humidity for it is 45%-66%

-

4. PH range for it is 5,5-6,5

Melon cultivation using hydroponic system need to have AB Mix requirement as such [5]:

-

1. When a melon crop has 4 leaves, hydroponic nutrient need to be at ± 400 ppm.

-

2. Until melon crops reach 2 weeks of age, nutrient need to be at ± 800 ppm.

-

3. After 2 weeks of age until flower appear, nutrient need to be at ± 1000 ppm.

-

4. When flower appear on the crop nutrient need to be at ± 1200 ppm.

-

5. When fruit appears on the crop nutrient need to be at ± 1500 ppm.

-

6. When net appears on the surface of the fruit, nutrient need to be at ± 1800 ppm.

Other concerns regarding melon crop cultivation is its vulnerability to pests and diseases. Once a melon get a pest or disease, it will be hard to cure. This research used greenhouse to prevent melon from getting pest or disease.

-

B. Machida Cultivation Method

In 2009 the Machida Chamber of Commerce and Industry adopted the Machida cultivation method. This method is made based on various techniques that have existed before. Using this method, melon plants, which generally produce 1-3 fruits per plant, can produce up to 60 fruits per crop [6]. The sugar content produced by the fruit exceeds 15%.

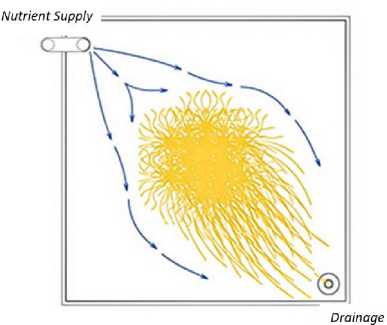

In a conventional hydroponic system, nutrient water

flows through the plant roots from the source, flows through the roots, and then flows through the roots of the next plant. In this case, due to the density of plant roots, nutrient water flows away from plant roots (due to high resistance). As a result, not all roots have access to nutrient water. Thus there will be roots that rot, and make the plant susceptible to disease.

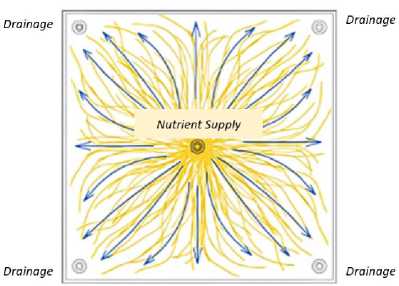

In the Machida cultivation method, the container for the crop is a square. The source of nutrient water is placed in the same position as the center of the plant roots (at the center point of the square), while holes are made in the four corners of the square where nutrient water can drain. Water will move from the center point in all directions, until it reaches the water drain hole. This causes plant roots to grow radially in all directions, thereby reducing root density. Thus, the nutrient water must pass through all the roots and the root density will be uniform throughout the root container [6]. Visually the difference between the flow of nutrient water in conventional hydroponics and Machida can be seen in Figure 2.

Figure 2. Nutrient Supply flow in conventional hydroponic system

Figure 3. Nutrient supply flow in machida method.

-

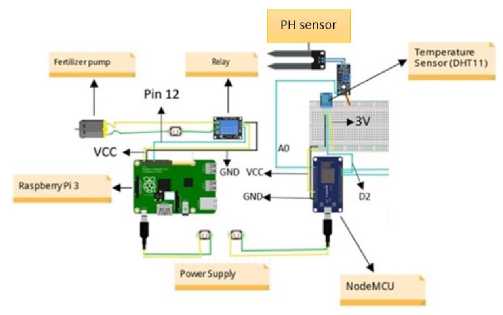

C. Internet of Things (IoT)

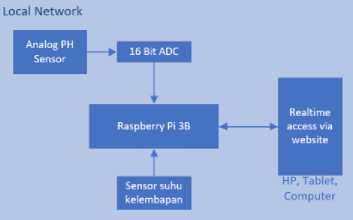

In this study, IoT will be used to monitor variables related to melon cultivation [4] so that the cultivation of melon crops become easier [7]. Those variables are temperature, humidity, and PH (see figure 4 for schematic diagram). TDS (Totally Dissolved Solid) sensor which is used to read how many of the AB Mix nutrient dissolved in hydroponic solution is not included in the IoT system. The reason is because the TDS sensor that available in the

market has the maximum detection of 1000 ppm. This specification cannot be used in this study because the nutrient dissolved for melon cultivation is above 1000 ppm. So this study used TDS meter device which is readily available in the market to read the TDS in the hydroponic solution.

Figure 4. IoT monitoring diagram schematic

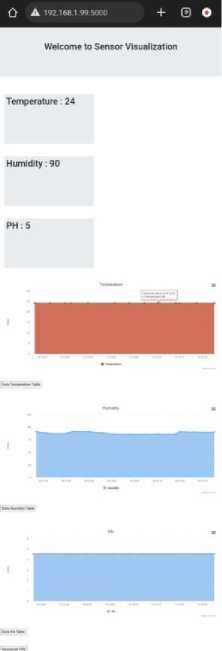

This study also used raspberry pi as a storage device for sensor reading and give flask web app service inside raspberry pi local server so that the data from sensor can be accessed through web application in real-time (see figure 5).

Figure 5.The IoT monitoring system

-

D. Hydroponic System.

Hydroponics is a technique of cultivating plants by using water as a medium for providing fertilizer to meet the nutritional needs of plants. Based on [9] hydroponic cultivation integrated with greenhouses is the best choice in terms of using inputs (nutrition, electricity, etc.) and increasing crop production. The nutritional needs of plants is usually met by dissolving AB Mix fertilizer into water in hydroponic system. This nutrient will be added to the water in the hydroponic system.

-

E. Greenhouse

Greenhouse is a place to control various plant cultivation activities to achieve the target of good conditions for plant growth. Close system make greenhouse a suitable place to avoid bad weather, disease and pest disturbances, as well as to create microclimate [8]. Because of these advantages Greenhouses are usually used in tandem with hydroponic system for crops cultivation.

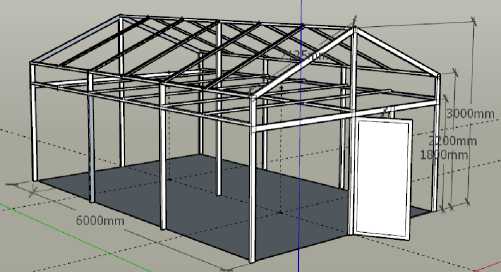

vines. The design implementation can be seen in Figure 6, while the implementation of the greenhouse in real world can be seen in Figure 7.

Figure 6. Greenhouse design.

Figure 7. Greenhouse Implementation

-

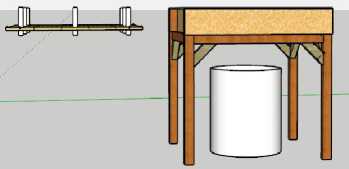

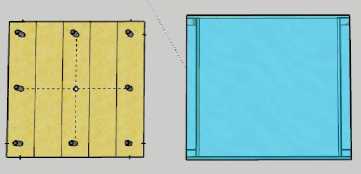

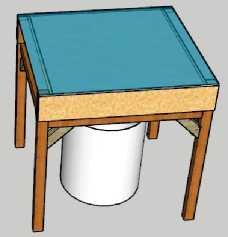

B. Design and Implementation of Crop Container

The container used as a place to grow melon plants is a cube container with a length, width and height of 1x1x0.2 meter cubic. This container will be filled with 15 cm high melon nutrient water. The detailed design of this cube is as follows (see figure 8):

-

1. The container gets its water supply from a 50 watt pump located in the bucker below the container.

-

2. The bottom of the container has 8 pipes through which water drains (left of figure 8 and figure 9).

-

3. The height of each pipe from the bottom of the container is 15 cm. This ensures that the water level in the container is 15 cm.

-

4. The water that comes out of each pipe will be forwarded to the bucket below the cube container.

-

A. Desain and Implementation of Greenhouse

The built greenhouse has a length, width and height of 4x6x3 meter cubic with a height of 2.2 meters for the melon

-

Figure 8. Container look from side view.

Figure 9. Container look from top view

Figure 10. Design of Melon Container

Figure 11. Implementation of Melon Container.

During the implementation process, the melon plant container underwent a slight modification. The imprecision between the size of the hole in the container made for the pipes and the size of the pipe at the bottom of the container, results in a change in the entry point for nutrient water into the melon plant container, namely from the top of the container. This is to prevent water from seeping in as it did the first time the pipes were buried at the bottom of the container. The implementation results of the melon container can be seen in Figure 11.

-

C. IoT System Implementation.

The implementation of the IoT system in this study was installed using a local network. The use of a local network here is intended so that if later this system is used by melon farmers, they do not need to pay routine fees to subscribe to cloud services so they can access data from their sensor readings. Simply by installing a switch and connecting the raspberry pi with the switch, all electronic equipment (cell phones, computers, and tablets) can access sensor data by accessing it on the raspberry pi via the website. This scheme can be seen in Figure 12.

Figure 12. Implementation of IoT System

This research used flask, a python-based micro web framework, for real-time data display without the need to use a database. All data that the sensor sends to Raspberry is stored in a file that can be accessed at a later date.

-

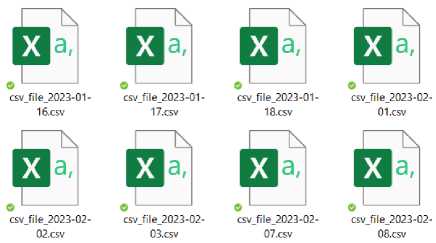

D. Data Collection and Presentation.

By using flask the research team can store complete data into files and also display data from sensors in real time. Historical data storage is stored in the form of files. Historical data storage is done every 1 hour. The justification for this is because the changes that occur will not be extreme. Then, to facilitate data access historically, data storage in files is divided per day. So that the data in 1 file is the result of storage on the same day or date. The file collection format that stores sensor data is csv. Figure 13 shows some of the files that have been collected.

Figure 13. Daily data collected from sensor

In this research, the website is design to be more friendly when viewed using a cellphone. This is for easier access, as cell phones are more likely to be within reach than other electronic devices. Figure 14 shows a screenshot of the website display to view sensor data in real time.

Figure 14. Realtime sensor reading viewed through cellphone web app.

-

A. Sensor reading.

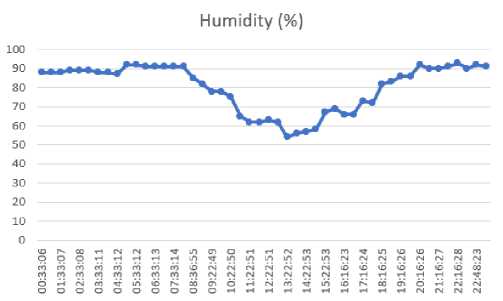

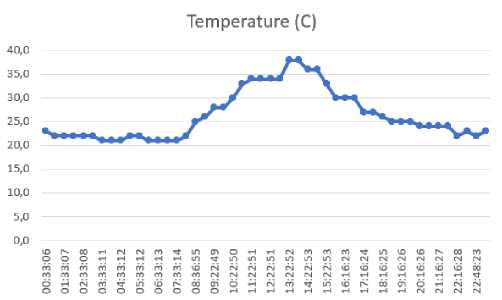

There are 3 sensors linked to the IoT systems. Temperature sensor (figure 15), Humidity Sensor (figure 16), and PH sensor (figure 17). The temperature inside the greenhouse rise in the morning and reach its peak around 13.20 WIB. Then the temperature descended and reached lowest at night. Unlike the temperature, the humidity inside the greenhouse reach its peak at night and reached its lowest point at afternoon, at the peak

Figure 16. Humidity variation in one day.

The temperature of the greenhouse is not optimal for melon crops. The ideal temperature is 16-30 degree Celsius, while the reading from figure 15 showed that the upper limit temperature was breached at midday. This reading is after the greenhouse door was opened during the day and closed during the night, less the temperature will be higher during the day (average temperature at the peak of the day during closed doors in the greenhouse was 42 degree Celsius).

The humidity inside the greenhouse will reach its peak during the high temperature. The effect of high humidity is an ever more heat felt by temperature sensor. At early morning the inside interior of the greenhouse would be full of water droplet as condensation happened during the night. The remedy for this also by opening the greenhouse door during the day, and close the door during night.

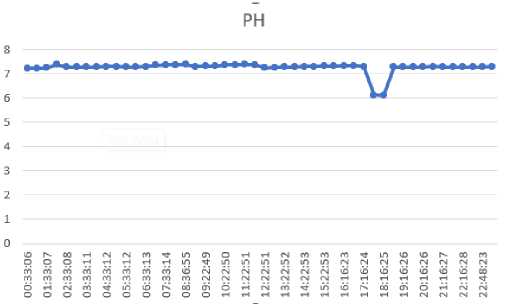

Looking at the PH of the nutrient water in the hydroponic system in figure 18 might be misleading without proper explanation. This is because most of the time the PH sensor was not dipped into the nutrient water but hanged in the air as shown in figure 19. The PH sensor specification stated that it must never be dipped the whole time into the nutrient water, less the sensor would be broken. So figure 18 means that the reading of PH was done at 18.00-18.30 WIB, but at other time PH sensor did not read anything but air.

temperature.

Figure 15. Temperature variation in one day.

Figure 17. PH measurement in one day.

Figure 18. PH sensor default position was hanging in the air.

-

B. Fruit of melon crop.

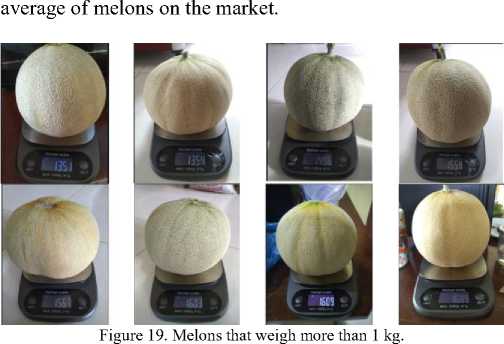

At the age of 2 months until death (approximately 3.5 months), there were 19 melon fruits that experienced growth. Of these 17 melons, 8 melons (figure 19) were harvested and had a mass of more than 1 kg (please see table 1 for details on the mass of each melon). While the other 9 fruits had a mass smaller than 1 kg at harvest. The level of sweetness produced by these 8 fruits is above the

Table 1. Weight detail of the 8 melon

|

Melon Fruit |

mass |

|

1 |

1,35 kg |

|

2 |

1,35 kg |

|

3 |

1,50 kg |

|

4 |

1,56 kg |

|

5 |

1,57 kg |

|

6 |

1,60 kg |

|

7 |

1,60 kg |

|

8 |

1,69 kg |

-

C. Leaves of melon crop

There growth of melon crops was uninhibited in any way during its lifetime. Figure 29-31 gave a glimpsed how the crops propagated in the greenhouse (at 1,5 months old).

Figure 20. Side view of melon crop

Figure 21. Upper view of melon crop

Figure 22. Below view of melon crop

When the melon crop are approximately 3 months old, the leaves on the plants begin to ripen. The ripening of the leaves of this plant occurs progressively, until eventually all the leaves of the plant were ripped (figure 23). Researchers have not been able to find the cause, whether it is caused by pests or melon crop had naturally reached the end of its natural life span (~3.5 months).

Figure 23. The ripening of the leaves of melon crop

-

D. Roots of melon crop

On the roots of melon crop moss was growing. The presence of moss makes the ability of roots to absorb nutrients hampered. The cause its existence is caused by the cover of the melon container which has not been able to block 100% of sunlight from reaching the hydroponic solution in the container. Figure 24 below gives an illustration of how much moss is found on the roots of melon plants.

Figure 24. Moss was growing on the root (colored green)

productivity of melon crop from 1-3 melon per crop to 8 per crop. All the 8 melons have mass greater than 1 kg and a level of sweetness above the average on the market. The creation of an IoT system for melons cannot run perfectly, because one of the main sensors, namely the TDS sensor, does not meet specifications. EC sensor is a candidate that basically equivalent to TDS sensor but at another price level. There are still room for improvement to ever increase the productivity of melon crop. First is to make sure moss won’t ever grow on the root of the melon. Second is to create a mechanism to control the temperature inside the greenhouse. Third is to create control system so that all variable that needed for the optimal growth of melon crop will always be satisfied.

Acknowledgment

This research was funded by the grant from LPPM IT Del in 2021/2022 fiscal year.

References

-

[1] Lester, G. (1997). Melon (Cucumis melo L.) fruit nutritional quality and health functionality. HortTechnology, 7(3), 222-227.

-

[2] Bangun, A. P. (2004). Menangkal penyakit dengan jus buah dan sayuran. AgroMedia. Jakarta.

-

[3] Badan Pusat Statistik. 2022. Produksi Tanaman Buah-buahan.

https://www.bps.go.id/indicator/55/62/1/produksi-tanaman-buah-buahan.html [31Maret 2022]

-

[4] Hwang, Y. H., Cho, K. H., Song, G. W., Shin, W. K., & Jeong, B. R. (1998). Effect of pinching and fruit setting, and planting density on fruit quality and yield of muskmelon cultured by deep flow technique. J Bio Fac Env, 7, 219-225.

-

[5] Tanam dan Panen Melon Hidroponik.Farmee.

https://farmee.id/tanam-dan-panen-melon-hidroponik/ [ 31 maret 2022]

-

[6] Machida Silk Melon [Internet]. Machida: The Machida Chamber of Commerce and Industry; 2023 [reviewed 2023 March 30; cited 2023 April 04]. Available from: http://www.machida-melon.jp/introduction-en/.

-

[7] Nasution, N., Rizal, M., Setiawan, D., & Hasan, M. A. (2020). IoT Dalam Agrobisnis Studi Kasus: Tanaman Selada Dalam Green House. IT Journal Research and Development, 4(2).

-

[8] Alahudin, M. (2013). Kondisi termal bangunan greenhouse dan screenhouse pada Fakultas Pertanian Universitas Musamus Merauke. Jurnal Ilmiah Mustek Anim Ha, 2(1).

V. Conclusion

This research has been successfully increase the productivity of melon plants. This method has been able to achieve the research purpose, which is increasing

Discussion and feedback