Culinary Innovation: Crackers Innovation Using Jatiluwih Red Rice Tea Dregs

on

E-Journal of Tourism Vol.10. No.2. (2023): 175-183

Culinary Innovation: Crackers Innovation Using Jatiluwih Red Rice Tea Dregs

Billy Tanius1*, Heru Pramudia1, Budi Riyanto2

-

1 Culinary Arts Program, Politeknik Internasional Bali 2 Podomoro University

*Corresponding Author: billy.tanius@pib.ac.id

DOI: https://doi.org/10.24922/eot.v10i2.103455

Article Info

Submitted:

June 28th 2023

Accepted:

September 20th 2023

Published:

September 30th 2023

Abstract

This study aimed to develop processed cracker products made from brown rice flour dregs. This research was experimental research. Based on the experimental results, brown rice tea dregs can be developed into three types of crackers that have different colors, aromas, tastes, textures & crispness, and shapes. Crackers were produced using the same method but with the addition of different ingredients; crackers A used wheat flour, crackers B used tapioca flour, and crackers C used brown rice flour. The organoleptic test involved 62 respondents who were asked to provide an assessment of the crackers produced. Based on the organoleptic test, it can be seen that in terms of texture and crunchiness, people liked crackers C the most, in terms of taste the people also liked crackers C the most, in terms of color the people liked the color of crackers B the most, in terms of smell the people liked the aroma of crackers C the most, and in terms of form, the community liked cracker B the most.

Keywords: brown rice; culinary; innovation; Jatiluwih.

INTRODUCTION

Background

Currently, Indonesian people are starting to switch to other sources of carbohydrates which have a more complete nutritional content than white rice or white rice. Indonesia is a country that produces a substitute for white rice or white rice, namely brown rice. Brown rice has a fiber level of 1.6%, while white rice has a fiber level of 0.56% (Hernawan & Meylani, 2016). In addition, brown rice bran has also been shown to contain natural oils and essential fats (Antika et al., 2018). The nutritional content of brown rice which is better than white rice causes brown rice to be

recommended for consumption by diabetics.

Although brown rice has high fiber and nutrient content, it is not very popular among community. Based on preliminary observations, people do not like brown rice because of the taste and price. The firmer taste and texture of brown rice is different from the softer taste and texture of white rice. That is why people not to like brown rice. In addition, brown rice is also sold at a higher price than the selling price of white rice. Reporting from www.harga.web.id the cheapest brown rice price is Rp. 18,000/ kg while the price of white rice per kilogram is Rp. 12,500. The price factor is a consideration for the

community in deciding household rice consumption (Dewi & Hayati, 2021).

Putra (2014) stated that Bali is an organic brown rice producing area, precisely in the Jatiluwih area. Jatiluwih brown rice is produced from the Oryza Sativa Barac Canana Jatiluwih rice variety which is grown organically without any chemical elements. Not using pesticides and the color, smell and taste of brown rice are very distinctive and different, making this brown rice a priority product. Jatiluwih rice has a relatively long maintenance period of around 145 days. At that time, farmers planted hybrid rice to secondary crops. After being harvested, Jatiluwih brown rice is usually stored in the rice barn. This rice is used for personal consumption, to stock up on seeds for the next planting season, and to sell.

Apart from being consumed in the household and sold, brown rice around Jatiluwih is also processed into other products. One of them is the processing of brown rice into tea (Noviyanti & Bhega-wati, 2019). The rice tea product that is produced is one of the priority products and souvenir products from the Jatiluwih area. Brown rice in Jatiluwih is also used as a cake ingredient, namely Lak-Lak, but this cake only lasts less than six hours. Since the cakes cannot be stored for longer time, the Lak-lak cake cannot be brought by visitors and cannot be stored for a long time.

Seeing the huge potential of brown rice to be processed into other excellent products, the researchers wanted to develop a processed product in the form of crackers made from rice tea dregs which were served when there were visitors in Jatiluwih. Crackers are one of the complementary foods and snacks that are familiar in the daily lives of Indonesian people. In addition, crackers can be stored for a longer period, especially raw or unprocessed crackers so visitors can buy and bring brown rice crackers to their region or country of origin. Residents around Jati-luwih can also process these crackers later http://ojs.unud.ac.id/index.php/eot

as a side dish for the main meal. The use of brown rice tea dregs is intended to optimize red rice tea dregs which still contains fiber and nutrients so that the dregs generated from brown rice tea can be minimized.

Based on the description of research background, generally the objective of this research was creating innovative products using Jatiluwih brown rice dregs to give added value to Jatiluwih brown rice. Moreover, the specific objectives of this research are as follows: (a) Developing innovative Jatiluwih brown rice crackers using Jatiluwih brown rice dregs; (b) Analyzing the level of community’s favorite due to the crackers produced in the research by doing organoleptic test.

LITERATURE REVIEW

This research was based on two major theories, namely the theory of cracker processing and the Culinary Product Development Model by Harrington (2004). The theory of cracker processing consists of diversification of crackers and the process of making crackers while the Culinary Product Development Model by Harrington (2004) explains procedures for carrying out or developing innovations in the culinary world.

Crackers (Crackers) are snacks made from tapioca flour dough mixed with seasonings such as shrimp or fish. Kerupuk are made by steaming the dough before it is cut into thin pieces, dried in the sun, and fried in plenty of cooking oil. Crackers have a crunchy texture and are often used as a complement to various foods. The composition of the cracker ingredients and their processing will greatly affect the quality of the crackers, where the composition of these ingredients also affects the development of the crackers. In general, the raw material used is tapioca flour, while the additional ingredients can be fish or shrimp, eggs or milk, salt, sugar, water, and seasonings consisting of shallots, garlic, coriander and so on (Herman, 2005). Crackers are defined as a type of dry food 176 e-ISSN 2407-392X. p-ISSN 2541-0857

made from ingredients that contain high levels of starch. In the process of making crackers, the starch must undergo a gelatinization process due to the addition of water and the heating treatment of the dough that is formed. The dough is made by mixing the main ingredients and the additional ingredients which are stirred until a tough and homogeneous dough is obtained (Wi-jandi et al., in Santoso, 2008). According to Rohhaendi (2009), crackers are a type of dry food that contains high levels of starch because they are generally made from tapioca. Crackers known to the public can be divided into two types, namely crackers with protein and crackers without protein. Furthermore, Purwanti (2011) diversified crackers from the approach of basic ingredients, price, taste, shape, and additional basic ingredients.

-

a. Diversification of crackers in terms of the type of basic ingredients

There are two materials used in the manufacture of crackers, namely raw materials, and additional materials. The ingredients used in making crackers include tapioca flour, wheat flour and rice. These materials can function as raw materials or additional materials, depending on the manufacturing technique. Additional ingredients can come from animals or plants. Examples of animal crackers: prawn crackers, mackerel crackers, milk crackers, cheese crackers. Examples of vegetable crackers: soybean crackers, wheat crackers, tapioca crackers of various shapes and colors.

-

b. Diversification of crackers in terms of taste

The various flavors of these crackers have motivated cracker manufacturers to create new types of crackers. If there are crackers with new shapes and flavors, consumers tend to try them. If it tastes good and suits the consumer's tongue, we can be sure they will be interested in buying it again.

-

c. Diversification of crackers in terms of price

The price of crackers in the community varies. These varying prices are influenced by the materials used, the packaging and the location where the crackers are sold.

-

d. Diversification of crackers in terms of shape

Crackers as a snack are widely known to the public, often found in the market in various forms. such as square, rectangular, round oval, semi-circle, star, gut, resembling shells, conch, and roses.

-

e. Diversify crackers with other ingredients

Crackers are generally processed using a variety of other ingredients besides the main ingredient. Other ingredients that are often used in making crackers are tapioca flour, wheat flour, brown rice flour, and other types of flour.

Making crackers through a series of processes. Maureen, Surjoseputro, and Epriliati (2016) mention seven stages of making crackers. These stages are as follows.

-

a. Dough making b. Printing c. steaming d. Cooling e. Cutting f. Drying

Research on the processing of brown rice into several processed products has been carried out by several researchers. The use of brown rice, especially the processing of brown rice bran in tempeh sausage, was carried out by Kusumastuti & Ayustaningwarno (2013). In that study, brown rice bran was added to tempe sausage. The purpose of this study was to determine the effect of adding brown rice bran on nutritional content, antioxidant activity and preference for tempe sausage. The study was conducted using an e-ISSN 2407-392X. p-ISSN 2541-0857

experimental method with a completely randomized design with one factor, namely the difference in the percentage of brown rice bran added to tempeh sausage. The percentage of adding brown rice bran was 0%, 2%, 5%, and 10%. Statistical analysis used a one-way ANOVA test followed by the Tukey test. The results showed that the greater the percentage of adding brown rice bran, the levels of protein, fat, carbohydrates, fiber and antioxidant activity of tempeh sausages increased. The highest levels of protein, fat, carbohydrates, fiber and antioxidant activity of tempeh sausage were found in tempeh sausage with the addition of 10% bran. However, the greater the percentage of brown rice bran added, the panelists tended to dislike tempeh sausage.

Ardhianditto, Anandito, Parnanto, & Rahmawati (2013) also conducted a study entitled Study of the Characteristics of Instant Baby Porridge Made from Yellow Millet Flour (Panicum sp) and Red Rice Flour (Orysa nivara) with Natural Ambon Banana Flavor (Musa X paradisiaca L) as ASI Complementary Food (MP-ASI). The purpose of this research was to study sensory properties with parameters of aroma, color, taste, texture and overall and to study physicochemical properties (proximate, antioxidant, color, water absorption, bulk density and solubility). Sensory test results were analyzed by one way ANOVA at a significance level of α = 5%. Then the physicochemical properties were tested, so that the best instant baby porridge formula was obtained. Based on the results of the study, the addition of brown rice flour can increase the nutritional content of the resulting porridge. The sensory test results showed that the sample with the addition of 10% brown rice flour was better than the control according to the panelists. The best formula in terms of sensory, physical and chemical properties is baby porridge with the addition of 10% brown rice.

METHODS

This study used a quantitative approach. Specifically, this research was conducted using the principles of the experimental method which is laboratory research. This experimental research method was chosen based on the formulation and research objectives. This research was conducted in two places, namely Jatiluwih Village and the Politeknik Internasional Bali campus. Raw materials in the form of brown rice tea dregs were taken from Jati-luwih Village. Formula or recipe trials were carried out at the Politeknik Internasional Bali campus.

This study usedquantitative data in the form of recipe formulas and the results of sensory tests and organoleptic tests. The formula or recipe was sourced from experimental tests conducted in the laboratory, namely the kitchen of the Bali International Polytechnic. While the organoleptic test data were obtained from research respondents. Experiments were carried out to produce recipes and formulas using two instruments, namely equipment and raw materials. The following is the equipment and raw materials needed. For the organoleptic test, the researcher used an assessment sheet for the respondents. The assessment component on the organoleptic test only contains the respondent's favorite component. The study involved 62 respondents.

Tabel 1. Ingredients

|

No. |

Ingridients |

Kode Eksperimen | ||

|

A (Wheat) |

B (Tapioca) |

C (Brown Rice) | ||

|

1 |

Brown rice tea dreg |

800 gr |

800 gr |

800 gr |

|

2 |

Wheat Flour |

800 gr |

- |

- |

|

3 |

Tapioca Flour |

- |

800 gr |

- |

|

4 |

Brow Rice Flour |

- |

- |

800 gr |

|

5 |

Salt |

40 gr |

40 gr |

40 gr |

|

6 |

Garlic |

40 gr |

40 gr |

40 gr |

|

7 |

Water |

300 gr |

300 gr |

300 gr |

RESULTS AND DISCUSSION

The results obtained in this study are the innovation of crackers made from brown rice tea waste and the results of organoleptic tests on the crackers produced.

Cracker Innovation Made from Red Rice Tea Dregs

In experiments conducted by researchers to produce innovative processed products using brown rice tea waste, researchers produced three types of crackers. The three types of crackers produced in this study were crackers using wheat flour, crackers using tapioca flour, and crackers using brown rice flour. The three types of crackers are produced through the same process but use different flour. The following is a description of the crackers produced in this study.

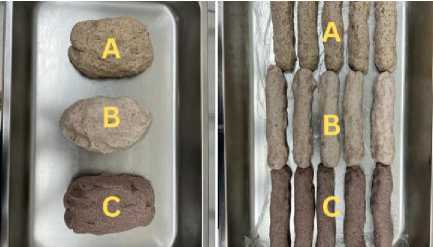

three cracker mixtures.

Figure 1. Differences in Color of Cracker

Dough

-

2. Aroma, Taste, Shape, and Texture of Crackers

The three crackers produced in this study had different aromas, tastes, shapes and textures. This is influenced by the difference in flour used to make the three

crackers. Differences in aroma, taste, shape and texture of crackers can be explained as follows.

-

1. Ingredients and Procedure

The three types of crackers produced in this study used almost the same ingredients with the same dosage. But the flour used to make crackers was different. Crackers A used wheat flour, crackers B used tapioca flour, and crackers C used brown rice flour. The materials used to produce these crackers are shown in Table 1. These materials are processed through the same process. The following is the procedure for making crackers A, crackers B, and crackers C.

-

1) Brown rice tea dregs are first steamed until cooked.

-

2) The dregs of cooked red rice tea are mixed with 100 grams of water until smooth.

-

3) Add all the ingredients to make a dough.

-

4) Divide the dough into 5 and shape into rice cake.

Considering that there were differences in the use of flour for the three crackers, the appearance of the dough for the three crackers is also different. Figure 1 shows the difference in the color of the http://ojs.unud.ac.id/index.php/eot

-

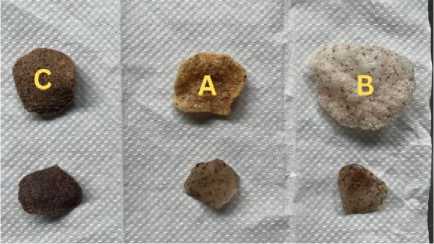

1. Crackers using wheat flour (A)

Crackers prepared using wheat flour do not have a distinctive or specific aroma. The aroma is the same as other crackers in general and also has the same aroma as the other two types of crackers produced in this study. These crackers are light brown in color. Cracker A has the same shape as cracker C which cannot expand when fried. Kerupuk A has a crunchy texture that is more similar to chips than to kerupuk. However, crackers A have a softer texture compared to chips. There was no difference in taste between the three crackers produced in this study.

-

2. Crackers using tapioca flour (B)

The second cracker is processed using tapioca flour. Similar to crackers A, these crackers using tapioca flour do not have a specific aroma. These crackers tend to have the same aroma as other crackers. Kerupuk B is white with red elements. Unlike crackers A and C, crackers B expand when fried in hot oil. Cracker B is a processed brown rice tea waste cracker which has the same texture as crackers in general 179 e-ISSN 2407-392X. p-ISSN 2541-0857

with a larger air cavity. However, crackers B have no difference in taste with crackers A and C.

-

3. Crackers using brown rice flour (C)

Crackers C is processed using brown rice flour. These crackers do not produce a distinctive aroma and have the same taste as crackers A and B. Crackers C also have a crunchy texture and resemble crackers. The texture of cracker C is denser than that of cracker A. Apart from the difference in texture, cracker C also has a difference in terms of color where cracker C has the darkest color among the other two crackers.

The different colors among those three crackers is shown in the Figure 2.

Figure 2. Three Crackers

The Results of Organoleptic Test

The innovation of brown rice tea waste-based crackers developed in the study was then tested to determine the level of public preference for the product being developed. The following are the results of the test of people's preference for the innovation of crackers made from brown rice tea waste.

Crackers using wheat flour (A)

To test the level of people's preference for Crackers A, the study provided a questionnaire containing five components, namely cracker texture and crispness, cracker taste, cracker color, cracker aroma, and cracker shape. Respondents were asked to provide an assessment by choosing the options they don't like, don't like, http://ojs.unud.ac.id/index.php/eot

quite like, like, and really like.

-

a. Cracker texture and crunch

The results of a simple analysis found that there were three respondents who really liked it, 12 respondents who liked it, 27 respondents who liked it moderately, 19 respondents who liked it less, and only 1 respondent who did not like it.

-

b. Cracker taste

Regarding the taste of crackers A, the following are the results of the analysis of the questionnaire. Of the 62 respondents, there were 3 respondents who said they really liked it, 17 respondents said they liked it, 35 respondents said they quite liked it, 7 respondents said they didn't like it very much, and no respondent chose not to like it.

-

c. Cracker color

In addition to looking at the texture and taste aspects, this study also analyzed the level of people's preference for the color of cracker A. Two out of 62 respondents said they really liked the color of cracker A, 16 respondents said they liked it, 25 respondents said they quite liked it, 18 respondents chose not to like it, and 1 respondent chose not to like.

-

d. Cracker aroma

About the aroma of crackers A, the results of the analysis show that 4 respondents said they really liked it, 35 respondents said they liked it, 21 respondents said they quite liked it, 1 respondent said they didn't like it very much, and no one chose not to like it.

-

e. Cracker shape

The last aspect assessed is the shape of the crackers. Based on the results of the analysis, it is known that there are 6 respondents who really like it, 33 respondents say they like it, 17 respondents say they quite like it, 6 respondents say they don't like it, and there are no respondents who don't like cracker A.

Crackers using tapioca flour (B)

The test of people's preference level for crackers B also used five aspects similar to those used to test the level of people's preference for crackers B, namely texture & crunchiness, taste, color, aroma, and shape. The assessment of the level of people's preference for crackers B also involved the same respondents and the responses that were the choices were very like, like, quite like, don't like, and don't like. The following is the result of an analysis of the level of people's preference for B crackers.

-

a. Cracker texture and crunch

Regarding the texture and crispness of crackers B, there were 16 respondents who said they really liked it, 15 respondents said they liked it, 23 respondents said they quite liked it, 8 respondents said they didn't like it very much, and no respondents said they didn't like it.

-

b. Cracker taste

The second assessment component is the aroma of crackers. The results showed that 11 respondents said they really liked it, 34 respondents said they liked it, 11 respondents said they quite liked it, 6 respondents said they didn't like it very much, and no respondents said they didn't like it.

-

c. Cracker color

Cracker color is the third component assessed. The results of the analysis showed that 30 respondents really liked it, 30 respondents liked it, 1 respondent quite liked it, 0 respondents did not like it, and 1 respondent did not like the color of crackers B.

-

d. Cracker aroma

The preference level test was also carried out to see the aroma component of the crackers. Of the 62 respondents involved, it was found that 6 respondents said they really liked it, 37 respondents said they liked it, 16 respondents said they

quite liked it, 1 respondent said they didn't like it very much, and 0 respondents said they didn't like it.

-

e. Cracker shape

The final component in the preference level test is the shape of the crackers. The results of the analysis found that 9 respondents said they really liked it, 47 respondents said they liked it, 6 respondents said they quite liked it, and no respondents said they didn't like it or didn't like it.

Crackers using brown rice flour (C)

Cracker C was also tested by applying five components, namely texture & crispness, taste, color, aroma, and cracker shape. Respondents who were involved in the test of people's preference level for cracker C were the same respondents as respondents for cracker A and cracker B. The following is the result of an analysis of the level of people's preference for cracker C.

-

a. Cracker texture and crunch

The texture and crispness of the crackers is the first aspect to be assessed. The results of the analysis showed that 27 respondents said they really liked it, 25 respondents said they liked it, 7 respondents said they quite liked it, 2 respondents said they didn't like it very much, and 1 person said they didn't like it.

-

b. Cracker taste

The second component is the cracker taste. Of the 62 respondents, there were 36 respondents who really liked it, 21 respondents who liked it, 3 respondents who liked it moderately, 2 respondents who liked it less, and no respondents who did not like it.

-

c. Cracker color

Based on the results of the analysis, the level of preference of respondents for the color of cracker C was 5 respondents said they really liked it, 5 respondents said they liked it, 16 respondents said they quite liked it, 30 respondents said they did not e-ISSN 2407-392X. p-ISSN 2541-0857

like it, and 6 respondents said they did not like it.

-

d. Cracker aroma

The results of the analysis found that out of 62 respondents, there were 12 respondents who really liked it, 36 respondents who liked it, 10 respondents who liked it moderately, 4 respondents who liked it less, and 0 respondents who did not like it.

-

e. Cracker shape

The shape of the crackers is the last component to be assessed. Based on the results of the analysis, it was found that 9 respondents said they really liked it, 39 respondents said they liked it, 8 respondents said they quite liked it, 6 respondents said they didn't like it very much, and 0 respondents said they didn't like it.

The results of the analysis of the respondents' preference level for crackers A, B, and C can be described in Figure 3.

People's Preferences

100%

80%

60%

40%

20%

0%

Texture Taste Color Aroma Shape

-

■A■B■C

Figure 3. The Results of Organoleptic Test

CONCLUSION

Based on the experimental results and data analysis, the following are some conclusions that can be drawn.

-

a. Brown rice tea dregs can be developed into three types of crackers that have different colors, aromas, tastes,

textures & crunchiness, as well as shapes. Crackers are produced using the same method but with the addition of different ingredients; crackers A use wheat flour, crackers B use tapioca flour, and crackers C use brown rice flour.

-

b. Based on the organoleptic test, it can be seen that in terms of texture and crunchiness, people like crackers C the most, in terms of taste the people also like crackers C the most, in terms of color the people like the color of crackers B the most, in terms of smell the people like the aroma of crackers C the most, and in terms of form, the community likes cracker B the most.

ACKNOWLEDGEMENT

The author would like to express his sincere gratitude for the almighty God for all the blessings and health so then the author was able to complete the research. The author would also like to thank Politeknik Internasional Bali for funding the research and providing feedbacks to improve the research and this academic writing. This research could not be possible without the support from the community of Jatiluwih, all colleagues at Politeknik Internasional Bali, and the author’s beloved family.

REFERENCES

Antika, E., Rakhmad, H., & Ishaq, F. N.

(2018). Penentuan Kualitas Mutu Beras Merah Berdasarkan Standart Nasional Indonesia Berbasis Pengolahan Citra Digital. Jurnal Informatika Polinema, 4(2), 125.

Ardhianditto, D., Anandito, R. B. K., Par-nanato, N. H. R., & Rahmawati, D. (2013). Kajian Karakteristik Bubur Bayi Instan Berbahan Dasar Tepung Millet Kuning (Panicum sp) dan Tepung Beras Merah (Orysa nivara) dengan Flavor Alami

Pisang Ambon (Musa X paradisi-aca L) sebagai Makanan Pendamping ASI (MP-ASI). Jurnal Teknosains Pangan, 2(1).

Dewi, R. C., & Hayati, M. (2021). Perilaku Konsumen dalam Keputusan Pembelian Beras Merah Organik.

Agriscience, 2(2), 295–313.

https://doi.org/10.21107/agrisci-ence.v2i2.11412

Harrington, R. J., & Ottenbacher, M. C. (2013). Managing the culinary innovation process: The case of new product development. Journal of Culinary Science and Technology, 11(1), 4–18.

Hernawan, E., & Meylani, V. (2016). Analisis Karakteristik Fisikokimia Beras Putih, Beras Merah, Dan Beras Hitam (Oryza sativa L., Oryza nivara dan Oryza sativa L. indica). Jurnal Kesehatan Bakti Tunas Hu-sada: Jurnal Ilmu-Ilmu Keperawa-tan, Analis Kesehatan Dan Farmasi, 15(1), 79.

https://doi.org/10.36465/jkbth.v15 i1.154

Kusumastuti, K., & Ayustaningwarno, F. (2013). Pengaruh Penambahan Bekatul Beras Merah terhadap Kandungan Gizi, Aktivitas Antioksidan dan Kesukaan Sosis Tempe. Journal of Nutrition College, 2(1), 27–34. http://ejournal-s1.undip.ac.id/index.php/jnc

Maureen, B., Surjoseputro, S., & Epriliati, I. (2016). Pengaruh Proporsi Tapikoka Dan Tepung Beras Merah Terhadap Sifat Fisikokimia Dan Organoleptik Kerupuk Beras Merah (Effect of proportion of tapioca and red rice flour on the physicochemical and organoleptic properties of red rice crackers). Jurnal Teknologi Pangan, 15 (1): 43, 1–10.

Noviyanti, P. L., & Bhegawati, D. A. S. (2019). Pengembangan Usaha Produk Teh Beras Merah Kelompok Wanita Tani Kuntum Sari di Dusun Wongaya Betan, Mengesta, Penebel, Tabanan, Provinsi Bali. Sarwahita: Jurnal Pengabdian Kepada Masyarakat, 16(1), 80–86.

Purwanti, H. (2011). Inovasi pembuatan kerupuk bawang dengan substitusi tepung kentang hitam [Universitas Negeri Semarang]. http://lib.un-nes.ac.id/5826/

Putra, R. P. (2014). Analisis Penetapan Harga Jual Beras Merah Organik di CV Jatiluwih RedRice, Kabupaten Tabanan, Provinsi Bali. Universitas Brawijaya

Rohaendi, D. 2009. Memproduksi Kerupuk Sangrai. Jakarta: PT. Gramedia Pustaka

http://ojs.unud.ac.id/index.php/eot

183

e-ISSN 2407-392X. p-ISSN 2541-0857

Discussion and feedback