Expanding Supply Chain Performance in Logistic and Forwarder Companies: How Collaboration Enhance Capabilities and Innovation Performance

on

I Wayan Edi Arsawan, Expanding Supply Chain… 61

P-ISSN: 1978-2853

E-ISSN: 2302-8890

MATRIK: JURNAL MANAJEMEN, STRATEGI BISNIS DAN KEWIRAUSAHAAN

Homepage: https://ojs.unud.ac.id/index.php/jmbk/index

Vol. 17 No. 1, Februari (2023), 61-72

Expanding Supply Chain Performance in Logistic and Forwarder Companies: How Collaboration Enhance Capabilities and Innovation Performance

SINTA 2

I Wayan Edi Arsawan

Department of Business Administration

Politeknik Negeri Bali

Email: wayanediarsawan@pnb.ac.id

DOI : https://doi.org/10.24843/MATRIK:JMBK.2023.v17.i01.p05

ABSTRACT

The changes in the business landscape between supply chains and the lack of literature on supply chains encourage scholars to investigate the relevant topic. The study aims to investigate the linkage between supply chain collaboration, capabilities, and innovation performance on supply chain performance in emerging country Indonesia. This study distributed questionnaires to 358 logistics managers and forwarders as research samples using a quantitative approach in Bali, Indonesia. The study’s results showed that supply chain collaboration significantly affected innovation performance, supply chain capabilities, and supply chain performance. In addition, innovation performance insignificant effected supply chain performance. Another crucial finding was supply chain capabilities partially mediate relationship between supply chain collaboration and supply chain performance. This result enhanced logistic and forwarder companies manager to strengthen their collaboration among partners. Theoretical and managerial implications were also discussed in this paper.

Keywords: Innovation Performance, Supply Chain Capabilities, Supply Chain Collaboration, Supply Chain Performance.

INTRODUCTION

The current business landscape is transforming from intercompany competition to supply chainbased competition (Baah, Acquah, et al., 2021; Baah, Opoku Agyeman, et al., 2021 . Given the critical function of the supply chain in improving operational performance (Truong et al., 2017 and other essential aspects of organizational agility (Arsawan, Hariyanti, et al., 2022 and sustainability performance (Salam et al., 2017 . Thus, organizations must collaborate intensely with stakeholders involved in the supply chain mechanism, i.e., producers, entrepreneurs, governments, and logistics companies (Y. Huang et al., 2020 . Given the vital function of the supply chain and all parties involved, developing a collaboration structure will improve performance and minimize multiple disruptions that may occur (L. Huang et al., 2020 . In the existing literature, the supply chain is a dynamic construct influenced by various determinants and viewpoints. For example, a study conducted by Rajaguru & Matanda (2019 found out how the role of collaboration forms a network that strengthens supply chain capability. Furthermore, collaboration improves coordination which has implications for increasing capabilities, innovation (Asree et al., 2018 , and performance (Liu et al., 2020; Mandal, 2017 .

The present study bridges the gaps in studies as follows. First, a previous study reveals that supply chain capabilities’ roles as a predictor of supply chain performance have yet to be extensively

explored (Hsin Chang et al., 2019 . At the same time, supply chain capabilities provide a strong foundation for building supply chain performance (S. H. Liao & Kuo, 2014 and holistic organizational performance (Aslam et al., 2020 . Second, in the literature regarding the supply chain, the role of innovation performance needs to be investigated and explored adequately (Hong, Liao, et al., 2019 because innovation performance has not been considered an essential trigger in building sustainable performance and competitiveness (Arsawan, Koval, et al., 2022 . Third, considering that Indonesia has a low ranking in terms of supply chain performance with very high logistics costs, strategic efforts are needed to improve this circumstance.

Fourth, there is a significant gap in supply chain management. Although the researchers can explain the effect of supply chain management activities on the operational performance of companies, they have yet to explore how supply chain management activities affect innovation performance to build competitive advantage. Cooperation between supply chain members can also generate a higher rate of transaction costs due to weak networking flexibility (Schmidt & Wagner, 2019 and make collaborative innovation and knowledge sharing in the supply chain more complex. They were constructed to reduce transactional costs and unpredictability, and the relationship quality between supply chain members is essential for collaborative innovation and knowledge sharing (Jean et al., 2014 . Related studies addressed the linkage between the quality of supply chain linkages and supply chain performance (Schmidt & Wagner, 2019; Tigga et al., 2021; Tsai & Hung, 2016 . Nevertheless, insights into the baseline mechanisms by which relationship quality affects firm innovation performance and the role of mediation are lagging. (Rungsithong et al., 2017 .

Thus, investigating the determinants of supply chain performance in Indonesia is based on three main reasons. First, having 17,000 islands requires Indonesia to build solid logistics and supply chain collaborations because it impacts operational costs, coordination costs, and performance. The ability to manage coordination and collaboration between supply chain partners will have a positive effect on strengthening cooperation and strengthening collaboration that it is inline with stakeholder theory (Freeman, 1998 . Second, logistics companies are the backbone of the distribution of goods and services in archipelagic countries. It occurs because only logistics companies can do good inter-regional cooperation through networking and collaboration (Paula et al., 2019; Pomponi et al., 2015 . Third, Indonesia needs infrastructure and comprehensive studies to build a supply chain to increase the global competitiveness index while reducing logistics costs (WEF, 2019 .

The existing literature reveals that supply chain collaboration aims to identify, use, and assimilate resources internally and externally and information to promote activities of the entire supply chain (S. H. Liao & Kuo, 2014 . Furthermore, collaboration is a mechanism for combining and testing capabilities that affect organizational operations (do Canto et al., 2020 . Interaction and collaboration between supply chain partners form a network that can help increase capability, effectiveness, and efficiency throughout the supply chain (Rajaguru & Matanda, 2019 . Intense cross-organizational collaboration, collaborative, and coordinating efforts enable organizations to build resources that enhance organizational capabilities, processes, and performance (Soosay & Hyland, 2015 . Furthermore, collaboration with stakeholders helps achieve the required supply chain coordination (Mandal, 2017 to enhance supply chain performance (Liu et al., 2020 . It aligns with previous findings (I. Wu et al., 2014 that the critical role of collaboration determines supply chain performance.

For logistics and forwarder companies, supply chain collaboration’s vital role is to enhance innovation performance sustainably (Cheng et al., 2014 . Organizations with solid collaboration with supply chain associates tend to have high innovation performance (Nguyen et al., 2019a . It occurs because of the diffusion and transfer of knowledge information, which has implications for collaborative innovation (Shin et al., 2019 . The quality of collaboration is an essential trigger for innovation performance because it involves collaboration, commitment, and communication (Li, 2020 ; thus, by supporting a collaborative relationship in the long term, innovation performance will be accomplished (Asree et al., 2018 . Therefore, these are the formulated hypotheses:

-

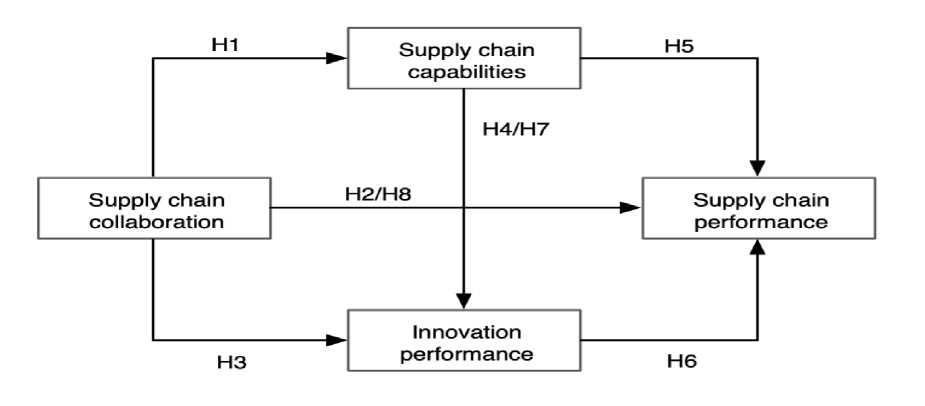

H1: Supply chain collaboration positively affects supply chain capabilities

-

H2: Supply chain collaboration positively affects supply chain performance H3: Supply chain collaboration positively affects innovation performance

Organizations develop their capabilities to meet the dynamic market to allow effective resource configuration (J. B. Barney, 2001 . Supply chain capability identifies, utilizes, and assimilates resources internally and externally to encourage these activities (S.-H. Liao et al., 2021 . Supply chain capabilities will improve operational capabilities and enable organizations to coordinate comprehensive resources to improve innovation performance (Y. Liao & Li, 2019 . Furthermore, previous studies found that supply chain capabilities considerably affect supply chain performance and organizational performance (Yu et al., 2018 . On the other hand, organizations with more outstanding SCM capabilities in flexibility, integration, and responsiveness have a significant supply chain performance (Flöthmann et al., 2018 . Thus, supply chain capabilities assist organizations’ accomplishment by increasing product availability, on-time shipments, and reducing inventory positions to boost supply chain performance (Asamoah et al., 2020 . The discussion leads to the formulated hypotheses:

-

H4: Supply chain capabilities positively affect innovation performance

-

H5: Supply chain capabilities positively affect supply chain performance

Innovation performance is an organization’s capability to enhance its products and services’ significance, usability, and performance (Hong, Liao, et al., 2019 . Improved supply chain performance can be acquired by encouraging relational exchange and innovation and collaborating with associates to detect areas needed for enhancement (Seo et al., 2014 . Innovation can affect interactions between producers, suppliers, and customers. Although there is extensive supply chain management literature, researchers seem to overlook the linkage between innovation performance and supply chain performance. To the authors’ knowledge, innovation performance will positively impact supply chain performance, especially in logistics. Eventually, the formulated hypothesis is: H6: Innovation performance positively affected supply chain performance

Supply chain collaboration with stakeholders (i.e., producers, suppliers, competitors, and other organizational units will improve innovation performance (Cheng et al., 2014 in building a competitive advantage for the members of the supply chain (Lim et al., 2017 . Enhancement of the quality of collaboration through networking, commitment, and building effective communication to reduce uncertainty is required to build sustainable innovation performance (Li, 2020 . Thus, it enhances supply chain capabilities and forms an effective and efficient network throughout the supply chain (Rajaguru & Matanda, 2019 . Finally, intense and robust collaboration improves the supply chain enabling organizations to increase innovation (Y. Liao & Li, 2019 . Hence, this is the formulated hypothesis: H7: Supply chain capabilities partially mediate the linkage between supply chain collaboration and innovation performance

Collaboration in the supply chain system will increase incremental and radical continuous innovation (Nguyen et al., 2019b; Yunus, 2018 , which improves supply chain performance (Asamoah et al., 2020 . The role of supply chain collaboration in this mediation framework is to improve innovation performance in building supply chain performance. Cooperation with supply chain associates will provide insight and experience to create innovation (Paula et al., 2019 to build sustainability among partners (Chen et al., 2017 , which generate supply chain performance (Baah, Opoku Agyeman, et al., 2021; Cheng et al., 2014 . Based on the description, the formulated hypothesis is:

-

H8: Innovation performance partially mediates the linkage between supply chain collaboration and supply chain performance.

Therefore, the study examines logistics and forwarder companies’ supply chain performance determinant model. Figure 1. depicts the research model.

Figure 1. Supply chain performance model

METHODS

The population was 179 companies affiliated with the Indonesian logistics and forwarder association. The sampling was a saturated sample, with the respondents being operational managers and chief directors. A total of 358 respondents were assumed to know strategic policies regarding the supply chain. Research variables measurement adopted previous research using a 1-7 Likert scale (“1-strongly disagreed – 7-strongly agreed” . Questionnaires were distributed online via Google Forms and collected for 3 months (October-December 2022 .

To measure the variables, we used the outputs of several empirical studies. Supply chain collaboration measurement was 4 dimensions and 16 indicators, i.e., 1 internal collaboration (3 indicators , 2 collaboration with suppliers (6 indicators , 3 collaboration with customers (4 indicators , and 4 collaboration with competitors and others (3 indicators was adapted from Chen et al. (2017 . Supply chain capabilities measurement was 4 dimensions with 17 indicators, i.e., 1 information exchange (4 indicators , 2 integration (4 indicators , 3 coordination (5 indicators , and 4 responsiveness (4 indicators adapted from the study Asamoah et al. (2020 and F. Wu et al. (2006 . Innovation performance measurement 3 dimensions and 9 indicators, i.e., 1 product innovation (3 indicators , 2 process innovation (3 indicators , and 3 management innovation (3 indicators adapted from Hong et al. (2019 . Supply chain performance measurement was 3 dimensions and 14 indicators, i.e., 1 reliability (5 indicators , 2 efficiency (4 indicators , and 3 flexibility (5 indicators adapted from previous studies (Asamoah et al., 2020; Koçoğlu et al., 2011; Lee et al., 2007 .

Furthermore, the data were analyzed using SEM-PLS (Hair Jr et al., 2017 and was predictive to test the model proposed in this study. In addition, with its soft assumptions, PLS provides strength power to explain research models (Hair et al., 2019 .

RESULTS AND DISCUSSION

This study involved 358 respondents from 179 companies engaged in logistics and forwarders in Bali Province by distributing questionnaires to operational managers and chief directors regarding strategic policies regarding supply chain management. The results of descriptive statistics revealed <5 years (5% , 6-10 years (32.7% , 11-15 years (15.3% , 16-20 years (30.4% , and >20 years (20.3% based on experience. When viewed from the age, the statistics indicated <25 years (5.7% , 25-30 years

(29.2% , 31-35 years (30.2% , 36-40 years (26.3% , and 41- 45 years (8.8% . The statistics showed males (66.7% and females (33.3% based on gender. Further, from educational level, the statistics denoted bachelor (81.6% , master (17.7% , and doctoral (0.7% .

Furthermore, to achieve the objectives of this research, we initially carried out the outer model measurement. Table 1. illustrates that the 69 items of the four key variables were the base of the present research model. This research model’s reliability was evaluated by Cronbach’s alpha (Hair Jr et al., 2016 . Table 1. reveals that Cronbach’s alpha values exceeded 0.7. Furthermore, the research model’s convergent validity was examined using average variance extract, composite reliability, and item reliability variable, respectively. According to experts’ suggestions (Hair Jr et al., 2017 , CR and AVE values must exceed 0.7. Thus, AVE and CR values met the criteria. The loading factors of the individuallevel items exceeded 0.7.

Table 1. Instrument reliability test

|

Second order constructs |

Items* |

Cronbach’s Alpha |

Rho_A |

Composite Reliability |

Average Variance Extracted (AVE) | ||

|

Supply chain |

Collaboration |

1.000 | |||||

|

collaboration |

IC |

0.766 |

0.847 |

0.876 |

0.710 | ||

|

CWS |

0.889 |

0.921 |

0.934 |

0.681 | |||

|

CWC |

0.857 |

0.868 |

0.897 |

0.678 | |||

|

CWCO |

0.847 |

0.851 |

0.912 |

0.765 | |||

|

Capabilities |

1.000 | ||||||

|

Supply chain |

IC |

0.842 |

0.966 |

0.894 |

0.724 | ||

|

capabilities |

INTEG |

0.843 |

0.877 |

0.883 |

0.693 | ||

|

COOR |

0.856 |

0.879 |

0.877 |

0.632 | |||

|

RESP |

0.861 |

0.887 |

0.921 |

0.735 | |||

|

Innovation P |

1.000 | ||||||

|

Innovation |

PROD |

0.855 |

0.874 |

0.922 |

0.786 | ||

|

performance |

PROC |

0.875 |

0.892 |

0.939 |

0.823 | ||

|

MAN |

0.898 |

0.879 |

0.932 |

0.836 | |||

|

Performance |

1.000 | ||||||

|

Supply chain |

REL |

0.821 |

0.825 |

0.869 |

0.633 | ||

|

performance |

EFFIC |

0.880 |

0.887 |

0.924 |

0.733 | ||

|

FLEX |

0.865 |

0.872 |

0.921 |

0.667 | |||

|

Table 2. Perbandingan √AVE dengan Korelasi Antar Variabel | |||||||

|

√AVE |

Coeficient of Correlation* | ||||||

|

Variables |

AVE |

SCCo |

SCCs |

IP |

SCP | ||

|

Supply chain collaboration |

0.541 |

0.736 |

1.000 | ||||

|

Supply chain capabilities |

0.591 |

0.769 |

0.417 |

1.000 | |||

|

Innovation performance |

0.532 |

0.729 |

0.387 |

0.564 |

1.000 | ||

|

Supply chain performance |

0.549 |

0.741 |

0.268 |

0.532 |

0.323 |

1.000 | |

Furthermore, according to experts’ criteria (Fornell & Larcker, 1981 , upon evaluating the square root of the AVE of each variable, when the first value of the upper side of the respective column

is the highest, it indicated the formation of discriminant validity (Fornell & Larcker, 1981; Hair et al., 2016 . Table 2. depicts correlation analysis based on the criteria.

The next step was to investigate the structural model to test the accuracy of the predictions and the associations between the variables, following the experts’ advice (Tenenhaus et al., 2005 using the goodness of fit with a value of 0.486 which signified high fitness. Furthermore, using R2 showed that the supply chain performance model was fit (27.6% . Meanwhile, the Q2 score was positive (0.913 , and all components have good predictive power (Chin et al., 2020 . After testing the outer and inner models, the next step was testing the research hypotheses. Table 3. presents information on the coefficient of the direct linkage between variables through the original sample and t statistics> 1.96 .

The data analysis showed that 5 of the 6 direct linkages supported the hypotheses (see Table 3. The linkage between supply chain collaboration and supply chain capabilities was significant (β=0.462, t-statistic 12.538 ; thus, hypothesis 1 was accepted. These results supported previous studies (Baah, Opoku Agyeman, et al., 2021; S. H. Liao & Kuo, 2014 that effective and efficient collaboration will improve supply chain capabilities through the integrity of resources to achieve supply chain capabilities (Rajaguru & Matanda, 2019 in planning, procurement, and sales targets (Chand et al., 2020 . The linkage between supply chain performance and supply chain collaboration (β=0.239, t statistics 6.160 was significant; hence, hypothesis 2 was accepted. The research results aligned with previous studies (Mandal, 2017; Mandal & Saravanan, 2019 that explained collaboration is a competitive area to improve performance by expanding mutually beneficial resources (Um & Kim, 2019 .

Table 3. Path coefficients

|

Constructs |

Original Sample (O) |

Sample Mean (M) |

Standard Deviation (STDEV) |

T Statistics (|O/STDEV|) |

P Values |

Decisions |

|

Supply Chain Collaboration -> Supply Chain Capabilities (H1) |

0.462 |

0.463 |

0.037 |

12.538 |

0.000 |

Supported |

|

Supply Chain Collaboration -> Supply Chain Performance (H2) |

0.239 |

0.238 |

0.039 |

6.160 |

0.000 |

Supported |

|

Supply Chain Collaboration -> Innovation Performance (H3) |

0.304 |

0.298 |

0.048 |

6.300 |

0.000 |

Supported |

|

Supply Chain Capabilities-> Innovation Performance (H4) |

0.252 |

0.256 |

0.047 |

5.345 |

0.000 |

Supported |

|

Supply Chain Capabilities -> Supply Chain Performance (H5) |

0.454 |

0.450 |

0.055 |

8.298 |

0.000 |

Supported |

|

Innovation Performance -> Supply Chain Performance (H6) |

0.006 |

0.004 |

0.039 |

0.165 |

0.876 |

Not Supported |

Furthermore, the linkage between innovation performance and supply chain collaboration (β=0.304, t-statistic 6.300 was significant; thus, hypothesis 3 was accepted. It reinforced the finding that collaboration is the basis for continuous innovation (Nguyen et al., 2019b . Collaborative relationships with key partners enabled innovation performance to be created due to creation (Asree et al., 2018 . The establishment of innovation performance through partner relationships enhanced the competitive advantage of the supply chain (Cheng et al., 2014 . Supply chain capabilities and innovation performance (β=0.252, t-statistics 5.354 had a significant linkage; thus, hypothesis 4 was accepted. It

supported the findings (Hong, Liao, et al., 2019 , which explained that supply chain capabilities increased value creation and innovation acceleration.

The linkage between supply chain capabilities and supply chain performance (β=0.454, t statistics 8.298 was significant; hence, hypothesis 5 was accepted. These results supported the findings (Asamoah et al., 2020; Rajaguru & Matanda, 2019 that supply chain capabilities helped organizations assimilate, identify, and use internal and external resources to facilitate all activities to achieve performance. Further, innovation and supply chain performance (β=0.006, t statistic 0.165 was insignificant; therefore, hypothesis 6 was rejected. It signified that innovation performance did not affect supply chain performance in logistics and forwarder companies. The result of the present study was contrary to previous studies (Seo et al., 2014; Singhry, 2015 that innovation was a vital predictor in building supply chain performance.

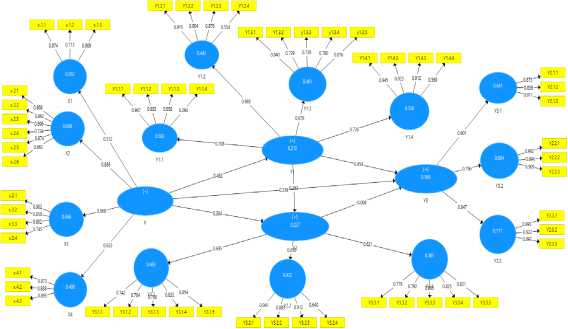

Furthermore, to evaluate mediation with the variance accounted for (VAF (Hair Jr et al., 2016 . (referensi method. There were two mediation pathways evaluated in this study. First, supply chain capabilities in the linkage between innovation performance and supply chain collaboration (0.116/0.420 . The VAF value was 0.276 (27.6% , which indicated a partial mediation; thus, hypothesis 7 was accepted. If the collaboration between supply chains goes well, it will increase capability, increasing innovation performance (Hong, Zheng, et al., 2019; Maldonado-Guzmán et al., 2019 . Second, we concluded that innovation performance did not mediate the linkage between supply chain performance and supply chain collaboration (0.001/0.240 . With the VAF value = 0.007 (7% , hypothesis 8 was rejected. The calculation results are illustrated in Table 4. and Figure 2.

Table 4. Mediation effects

|

Link* |

Mediator |

Independent Variable^ Mediator |

Mediator÷ Dependent Variable |

Direct |

Indirect |

Total effect |

VAF (%) |

Decisions |

|

SCCol-IP |

SCCap |

0.462 |

0.252 |

0.304 |

0.116 |

0.420 |

0.276 |

H7=Partial mediation |

|

SCCol- |

Innov |

0.304 |

0.006 |

0.239 |

0.001 |

0.240 |

0.007 |

H8= No mediation |

SCP

The analysis denoted that this study enriched the insight into supply chain management in five aspects. First, the results of this study revealed that collaboration develops supply chain capabilities (Biotto et al., 2012; Shin et al., 2019 and innovation performance (Ferraris et al., 2021; Hong, Zheng, et al., 2019 . Consequently, this study contributed to a comprehensive understanding of improving supply chain performance (Baah, Opoku Agyeman, et al., 2021; Cheng et al., 2014; S. H. Liao & Kuo, 2014 . Second, the study showed that innovation performance was affected by supply chain collaboration and supply chain capabilities, which answered the gaps in the literature from Y. Liao & Li (2019 . To the authors’ knowledge, there has yet to be a study that attempts to initiate an evident linkage between different types of collaboration and capabilities to achieve innovative performance and eventually gain a more comprehensive understanding (Bravo et al., 2017; Zimmermann et al., 2016 . An integrated perspective was required to understand how collaboration and capabilities mutually reinforced innovation performance in the supply chain context (Asree et al., 2018 .

Figure 2. SmartPLS Output analysis

Third, unexpectedly, the innovation performance effect was insignificant on supply chain performance. It implied that innovation performance did not affect supply chain performance in logistics and forwarder companies. The results contradicted previous studies, which stated that innovation is a primary predictor in establishing supply chain performance (Seo et al., 2014; Singhry, 2015 . The possible explanation was that logistics and forwarder companies focused more on distributing products and services. Subsequently, they only required innovation occasionally.

Fourth, supply chain capabilities partially mediated the linkage between supply chain collaboration and innovation performance. If the collaboration between supply chains goes well, it will increase capability, increasing innovation performance (Hong, Zheng, et al., 2019; Maldonado-Guzmán et al., 2019 . Fifth, in the aspect of the theory, this study enhanced stakeholder theory (Freeman, 1998 through mutually beneficial collaboration configurations between associates. The strength of collaboration provides superiority in knowledge and dynamic capabilities to generate a sustainable competitive advantage (J. Barney, 1991 .

CONCLUSIONS

Three crucial conclusions were yielded from this study. First, collaboration is the foundation for building supply chain capability, innovation, and performance. Second, innovation performance insignificantly affects supply chain performance. Third, supply chain capabilities partially mediate the linkage between supply chain collaboration and innovation performance. Although this study offers theoretical and managerial significance, there are limitations to be addressed. First, supply chain collaboration has several dimensions, such as customer integration, internal integration, and supplier integration have yet to be explored in this study. Hence, we recommend re-examining the above model by splitting these dimensions into key variables for further research. Second, this study is based on 358 responses from 179 logistics and forwarder companies in Bali, Indonesia to evaluate the hypotheses. Thus, the forthcoming study must consider acquiring diverse data from different countries to increase generalizability.

REFERENCES

Arsawan, I. W. E., Hariyanti, N. K. D., Atmaja, I. M. A. D. S., Suhartanto, D., & Koval, V. (2022 . Developing Organizational Agility in SMEs: An Investigation of Innovation’s Roles and Strategic Flexibility. Journal of Open Innovation: Technology, Market, and Complexity, 8(3 , 149. https://doi.org/10.3390/joitmc8030149

Arsawan, I. W. E., Koval, V., Rajiani, I., Rustiarini, N. W., Supartha, W. G., & Suryantini, N. P. S. (2022 . Leveraging knowledge sharing and innovation culture into SMEs sustainable competitive

advantage. International Journal of Productivity and Performance Management, 71(2 , 405–428. https://doi.org/10.1108/IJPPM-04-2020-0192

Asamoah, D., Agyei-Owusu, B., Andoh-Baidoo, F. K., & Ayaburi, E. (2020 . Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. International Journal of Information Management, June, 102195.

https://doi.org/10.1016/j.ijinfomgt.2020.102195

Aslam, H., Blome, C., Roscoe, S., & Azhar, T. M. (2020 . Determining the antecedents of dynamic supply chain capabilities. Supply Chain Management, 25(4 , 427–442.

https://doi.org/10.1108/SCM-02-2019-0074

Asree, S., Cherikh, M., & Gopalan, S. (2018 . The impact of supply chain responsiveness and strategic supply chain collaboration on innovation performance. International Journal of Business Performance and Supply Chain Modelling, 10(2 , 131–145.

Baah, C., Acquah, I. S. K., & Ofori, D. (2021 . Exploring the influence of supply chain collaboration on supply chain visibility, stakeholder trust, environmental and financial performances: a partial least square approach. Benchmarking: An International Journal.

Baah, C., Opoku Agyeman, D., Acquah, I. S. K., Agyabeng-Mensah, Y., Afum, E., Issau, K., Ofori, D., & Faibil, D. (2021 . Effect of information sharing in supply chains: understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmarking: An International Journal, ahead-of-p(ahead-of-print . https://doi.org/10.1108/BIJ-08-2020-0453

Barney, J. (1991 . Firm Resources and Sustained Competitive Advantage. Journal of Management, 17(1 , 99–120. https://doi.org/10.1177/014920639101700108

Barney, J. B. (2001 . Resource-based theories of competitive advantage: A ten-year retrospective on the resource-based view. Journal of Management, 27(6 , 643–650.

Biotto, M., de Toni, A. F., & Nonino, F. (2012 . Knowledge and cultural diffusion along the supply chain as drivers of product quality improvement. The International Journal of Logistics Management.

Bravo, M. I. R., Montes, F. J. L., & Moreno, A. R. (2017 . Open innovation in supply networks: an expectation disconfirmation theory perspective. Journal of Business & Industrial Marketing.

Chand, P., Thakkar, J. J., & Ghosh, K. K. (2020 . Analysis of supply chain performance metrics for Indian mining & earthmoving equipment manufacturing companies using hybrid MCDM model. Resources Policy, 68(April , 101742. https://doi.org/10.1016/j.resourpol.2020.101742

Chen, L., Zhao, X., Tang, O., Price, L., Zhang, S., & Zhu, W. (2017 . Supply chain collaboration for sustainability: A literature review and future research agenda. International Journal of Production Economics, 194(April , 73–87. https://doi.org/10.1016/j.ijpe.2017.04.005

Cheng, J. H., Chen, M. C., & Huang, C. M. (2014 . Assessing inter-organizational innovation performance through relational governance and dynamic capabilities in supply chains. Supply Chain Management, 19(2 , 173–186. https://doi.org/10.1108/SCM-05-2013-0162

Chin, W., Cheah, J. H., Liu, Y., Ting, H., Lim, X. J., & Cham, T. H. (2020 . Demystifying the role of causal-predictive modeling using partial least squares structural equation modeling in information systems research. Industrial Management and Data Systems, 120(12 .

https://doi.org/10.1108/IMDS-10-2019-0529

do Canto, N. R., Bossle, M. B., Marques, L., & Dutra, M. (2020 . Supply chain collaboration for sustainability: a qualitative investigation of food supply chains in Brazil. Management of Environmental Quality: An International Journal. https://doi.org/10.1108/MEQ-12-2019-0275

Ferraris, A., Giachino, C., Ciampi, F., & Couturier, J. (2021 . R&D internationalization in mediumsized firms: The moderating role of knowledge management in enhancing innovation performances. Journal of Business Research, 128(November 2019 , 711–718.

https://doi.org/10.1016/j.jbusres.2019.11.003

Flöthmann, C., Hoberg, K., & Gammelgaard, B. (2018 . Disentangling supply chain management competencies and their impact on performance: A knowledge-based view. International Journal

of Physical Distribution and Logistics Management, 48(6 , 630–655.

https://doi.org/10.1108/IJPDLM-02-2017-0120

Fornell, C., & Larcker, D. F. (1981 . Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research, 18(1 , 39–50.

https://doi.org/10.1177/002224378101800104

Freeman, E. R. (1998 . A Stakeholder Theory of Modern Corporation In Hartman. Perspectives in Business.

Hair, J. F., Hult, G., Tomas, M., Ringle, C. M., & Sarstedt, M. (2016 . A primer on partial least squares structural equation modeling (PLS-SEM). Sage publications.

Hair, J. F., Risher, J. J., Sarstedt, M., & Ringle, C. M. (2019 . When to use and how to report the results of PLS-SEM. In European Business Review (Vol. 31, Issue 1 . https://doi.org/10.1108/EBR-11-2018-0203

Hair Jr, J. F., Matthews, L. M., Matthews, R. L., & Sarstedt, M. (2017 . PLS-SEM or CB-SEM: updated guidelines on which method to use. International Journal of Multivariate Data Analysis, 1(2 , 107–123.

Hair Jr, J. F., Sarstedt, M., Matthews, L. M., & Ringle, C. M. (2016 . Identifying and treating unobserved heterogeneity with FIMIX-PLS: part I–method. European Business Review, 28(1 , 63–76. https://doi.org/10.1108/EBR-09-2015-0094

Hong, J., Liao, Y., Zhang, Y., & Yu, Z. (2019 . The effect of supply chain quality management practices and capabilities on operational and innovation performance: Evidence from Chinese manufacturers. International Journal of Production Economics, 212(August 2018 , 227–235. https://doi.org/10.1016/j.ijpe.2019.01.036

Hong, J., Zheng, R., Deng, H., & Zhou, Y. (2019 . Green supply chain collaborative innovation, absorptive capacity and innovation performance: Evidence from China. Journal of Cleaner Production, 241, 118377. https://doi.org/10.1016/j.jclepro.2019.118377

Hsin Chang, H., Hong Wong, K., & Sheng Chiu, W. (2019 . The effects of business systems leveraging on supply chain performance: Process innovation and uncertainty as moderators. Information and Management, 56(6 , 103140. https://doi.org/10.1016/j.im.2019.01.002

Huang, L., Murong, L., & Wang, W. (2020 . Green closed-loop supply chain network design considering cost control and CO2 emission. Modern Supply Chain Research and Applications.

Huang, Y., Han, W., & Macbeth, D. K. (2020 . The complexity of collaboration in supply chain networks. Supply Chain Management, 25(3 , 393–410. https://doi.org/10.1108/SCM-11-2018-0382

Jean, R. “Bryan,” Sinkovics, R. R., & Hiebaum, T. P. (2014 . The Effects of Supplier Involvement and Knowledge Protection on Product Innovation in Customer–Supplier Relationships: A Study of Global Automotive Suppliers in C hina. Journal of Product Innovation Management, 31(1 , 98– 113.

Koçoğlu, İ., İmamoğlu, S. Z., İnce, H., & Keskin, H. (2011 . The effect of supply chain integration on information sharing: Enhancing the supply chain performance. Procedia-Social and Behavioral Sciences, 24, 1630–1649.

Lee, C. W., Kwon, I. G., & Severance, D. (2007 . Relationship between supply chain performance and degree of linkage among supplier, internal integration, and customer. Supply Chain Management: An International Journal.

Li, G. (2020 . The impact of supply chain relationship quality on knowledge sharing and innovation performance: evidence from Chinese manufacturing industry. Journal of Business and Industrial Marketing, June. https://doi.org/10.1108/JBIM-02-2020-0109

Liao, S. H., & Kuo, F. I. (2014 . The study of relationships between the collaboration for supply chain, supply chain capabilities and firm performance: A case of the Taiwans TFT-LCD industry. International Journal of Production Economics, 156, 295–304.

https://doi.org/10.1016/j.ijpe.2014.06.020

Liao, S.-H., Hu, D.-C., & Chen, S.-T. (2021 . Supply chain integration, capability and performance – a business-to-business network cooperation. Journal of Business & Industrial Marketing, ahead-of-p(ahead-of-print . https://doi.org/10.1108/JBIM-10-2020-0467

Liao, Y., & Li, Y. (2019 . Complementarity effect of supply chain competencies on innovation capability. Business Process Management Journal, 25(6 , 1251–1272.

https://doi.org/10.1108/BPMJ-04-2018-0115

Lim, J.-S., Darley, W. K., & Marion, D. (2017 . Market orientation, innovation commercialization capability and firm performance relationships: the moderating role of supply chain influence. Journal of Business & Industrial Marketing.

Liu, W., Liang, Y., Wei, S., & Wu, P. (2020 . The organizational collaboration framework of smart logistics ecological chain: a multi-case study in China. Industrial Management and Data Systems. https://doi.org/10.1108/IMDS-02-2020-0082

Maldonado-Guzmán, G., Garza-Reyes, J. A., Pinzón-Castro, S. Y., & Kumar, V. (2019 . Innovation capabilities and performance: are they truly linked in SMEs? International Journal of Innovation Science, 11(1 . https://doi.org/10.1108/IJIS-12-2017-0139

Mandal, S. (2017 . The influence of dynamic capabilities on hospital-supplier collaboration and hospital supply chain performance. International Journal of Operations and Production Management, 37(5 , 664–684. https://doi.org/10.1108/IJOPM-05-2016-0249

Mandal, S., & Saravanan, D. (2019 . Exploring the Influence of Strategic Orientations on Tourism Supply Chain Agility and Resilience: An Empirical Investigation. Tourism Planning & Development, 16(6 , 612–636. https://doi.org/doi: 10.1080/21568316.2018.1561506

Nguyen, M. A. T., Lei, H., Vu, K. D., & Le, P. B. (2019a . The role of cognitive proximity on supply chain collaboration for radical and incremental innovation: a study of a transition economy. Journal of Business and Industrial Marketing, 34(3 , 591–604. https://doi.org/10.1108/JBIM-07-2017-0163

Nguyen, M. A. T., Lei, H., Vu, K. D., & Le, P. B. (2019b . The role of cognitive proximity on supply chain collaboration for radical and incremental innovation: a study of a transition economy. Journal of Business & Industrial Marketing.

Paula, I. C. de, Campos, E. A. R. de, Pagani, R. N., Guarnieri, P., & Kaviani, M. A. (2019 . Are collaboration and trust sources for innovation in the reverse logistics? Insights from a systematic literature review. Supply Chain Management, 25(2 , 176–222. https://doi.org/10.1108/SCM-03-2018-0129

Pomponi, P., Fratocchi, L., & Tafuri, S. R. (2015 . Trust development and horizontal collaboration in logistics: a theory based evolutionary framework. Supply Chain Management: An International Journal, 20(1 , 83–97.

Rajaguru, R., & Matanda, M. J. (2019 . Role of compatibility and supply chain process integration in facilitating supply chain capabilities and organizational performance. Supply Chain Management, 24(2 , 315–330. https://doi.org/10.1108/SCM-05-2017-0187

Rungsithong, R., Meyer, K. E., & Roath, A. S. (2017 . Relational capabilities in Thai buyer-supplier relationships. Journal of Business & Industrial Marketing.

Salam, M. A., Ali, M., & Seny Kan, K. A. (2017 . Analyzing supply chain uncertainty to deliver sustainable operational performance: Symmetrical and asymmetrical modeling approaches. In Sustainability (Vol. 9, Issue 12, pp. 1–17 . https://doi.org/10.3390/su9122217

Schmidt, C. G., & Wagner, S. M. (2019 . Blockchain and supply chain relations: A transaction cost theory perspective. Journal of Purchasing and Supply Management, 25(4 , 100552.

Seo, Y. J., Dinwoodie, J., & Kwak, D. W. (2014 . The impact of innovativeness on supply chain performance: is supply chain integration a missing link? Supply Chain Management, 19, 733–746. https://doi.org/10.1108/SCM-02-2014-0058

Shin, N., Park, S. H., & Park, S. (2019 . Partnership-based supply chain collaboration: Impact on commitment, innovation, and firm performance. In Sustainability (Vol. 11, Issue 2, pp. 1–19 . https://doi.org/10.3390/su11020449

Singhry, H. B. (2015 . Effect of Supply Chain Technology, Supply Chain Collaboration and Innovation Capability on Supply Chain Performance of Manufacturing Companies. Journal of Business Studies Quarterly, 7(2 , 258–273.

http://ezproxy.library.usyd.edu.au/login?url=https://search.proquest.com/docview/1755024806?a ccountid=14757%0Ahttp://dd8gh5yx7k.search.serialssolutions.com?ctx_ver=Z39.88-2004&ctx_enc=info:ofi/enc:UTF-8&rfr_id=info:sid/ProQ%3Acentral&rft_val_fmt=info:ofi/

Soosay, C. A., & Hyland, P. (2015 . A decade of supply chain collaboration and directions for future research. Supply Chain Management, 20(6 , 613–630. https://doi.org/10.1108/SCM-06-2015-0217

Tenenhaus, M., Vinzi, V. E., Chatelin, Y.-M., & Lauro, C. (2005 . PLS path modeling. Computational Statistics & Data Analysis, 48(1 , 159–205.

Tigga, G. A., Kannabiran, G., & Arumugam, V. (2021 . Exploring relationships among IT advancement, IT assimilation, supply chain capabilities and supply chain performance. Journal of Decision Systems, 1–25.

Truong, H. Q., Sameiro, M., Fernandes, A. C., Sampaio, P., Duong, B. A. T., Duong, H. H., & Vilhenac, E. (2017 . Supply chain management practices and firms’ operational performance. International Journal of Quality & Reliability Management, 34(2 , 176–193. https://doi.org/10.1108/IJQRM-05-2015-0072

Tsai, J.-M., & Hung, S.-W. (2016 . Supply chain relationship quality and performance in technological turbulence: an artificial neural network approach. International Journal of Production Research, 54(9 , 2757–2770.

Um, K.-H., & Kim, S.-M. (2019 . The effects of supply chain collaboration on performance and transaction cost advantage: The moderation and nonlinear effects of governance mechanisms. International Journal of Production Economics, 217, 97–111.

WEF. (2019 . The Global Competitiveness Report.

Wu, F., Yeniyurt, S., Kim, D., & Cavusgil, S. T. (2006 . The impact of information technology on supply chain capabilities and firm performance: A resource-based view. Industrial Marketing Management, 35(4 , 493–504. https://doi.org/10.1016/j.indmarman.2005.05.003

Wu, I., Chuang, C., & Hsu, C. (2014 . Int . J . Production Economics Information sharing and collaborative behaviors in enabling supply chain performance : A social exchange perspective. Intern. Journal of Production Economics, 148, 122–132.

https://doi.org/10.1016/j.ijpe.2013.09.016

Yu, W., Chavez, R., Jacobs, M. A., & Feng, M. (2018 . Data-driven supply chain capabilities and performance: A resource-based view. Transportation Research Part E: Logistics and

Transportation Review, 114, 371–385. https://doi.org/10.1016/j.tre.2017.04.002

Yunus, E. N. (2018 . Leveraging supply chain collaboration in pursuing radical innovation. International Journal of Innovation Science, 10(3 , 350–370. https://doi.org/10.1108/IJIS-05-2017-0039

Zimmermann, R., Ferreira, L. M. D. F., & Moreira, A. C. (2016 . The influence of supply chain on the innovation process: a systematic literature review. Supply Chain Management: An International Journal.

Discussion and feedback