IDENTIFICATION OF AGARWOOD SAPWOOD CHEMICAL COMPONENTS FROM FUNGAL INOCULATION RESULTS ON Gyrinops versteegii (Gilg.) DOMKE PLANTS

on

INTERNATIONAL JOURNAL OF BIOSCIENCES AND BIOTECHNOLOGY • Vol. 8 No. 1 • September 2020

eISSN: 2655-9994

pISSN: 2303-3371

https://doi.org/10.24843/IJBB.2020.v08.i01.p05

IDENTIFICATION OF AGARWOOD SAPWOOD CHEMICAL COMPONENTS FROM FUNGAL INOCULATION RESULTS ON Gyrinops versteegii (Gilg.) DOMKE PLANTS

I M. Mega* and N.L. Kartini

Agroecotechnology Study Program, Faculty of Agriculture, Udayana University Jl. PB. Sudirman, Denpasar, Bali 80232, Indonesia *Corresponding author: mega_made@yahoo.com

ABSTRACT

Agarwood is one of non-timber forest product comodites (NTFPs) which has high economic value and as an export commodity. Agarwood produce an aromatic resin substance in the form of lumps that located between the wood cells in various shapes and colors. According to Indonesian National Standards, the category of agarwood is classified into several levels such as agarwood sapwood, kemedangan, and agarwood powder. The classification system is based on color, weight, and aroma. This classification method shows that the current quality of agarwood welding systems is still subjective. Therefore, more objective welding system is needed which is related to the chemical composition and resin content. This study objective is to identify the chemical components of agarwood sapwood from the results of fungal inoculation in agarwood-producing plants of gyrinops versteegii. The research conducted by extracting agarwood sapwood sample using acetone. This agarwood sapwood sample collected from the result of Fusarium, Rhizopus and Trichoderma fungi inoculation for 1 year. Furthermore, the agarwood acetone extract fractionated with a gradient column chromatography with hexane-ethyl acetate eluent. The method to identify the compounds/component is using chromatography gas-spectro-photometer mass (GC-MS). The results showed that the chemical components contained in agarwood from fungal inoculation were mostly in the form of ester compounds. The highest types compounds and the highest density compound were found in agarwood produced by Trichoderma fungi inoculant, namely Hexanedioic acid, dioctyl ester; 11-octadecanoic acid, methyl ester; Cyclopropanedodecanoic acid, 2-octyl-, methyl ester; 9-octadecanoic acid, methyl ester; Octadecanoic acid, 9.10-dihydroxy-, methyl ester; Cyclopropanepentanoic acid, 2-undecyl-, methyl ester; Pentadecanoic acid, 14-methyl-, methyl ester; and non-ester compounds, namely: 2-tridecen-I-ol; 2- (2 ’, 4’, 4 ’, 6’, 6 ’, 8’, 8’Heptamethyltetrasiloxan -2 ’; 3-Hydroxybutanamide. 8-methoxy-2- (2.

Keywords: agarwood sapwood, extraction, chemical components, GC-MS

INTRODUCTION

Agarwood sapwood is a solid lump product with brownish-black color or black color that has a nice fragrance and produced on the wood or roots of the host tree (for example Aquilaria sp.). The wood part

underwent a process of physical and chemical changes due to the infection of fungi (Faizal and Esyanti, 2018).

Agarwood is one of the non-timber forest product commodities (NTFPs) that has high economic value, as an export

commodity, and a good source of income for the community (Pasaribu et al., 2013). Besides, the government has declared agarwood as a national non-timber forest product commodity that needs to be developed on a broader scale (Santosa, 2009). The great number of agarwood sapwood demands abroad because of the benefits of agarwood such as perfume, cosmetics, medicines, and religious ritual purposes (Akter et al., 2013).

The formation of agarwood sapwood is influenced by various factors such as the genetics of agarwood-producing trees, inducing microbes, the environment, and the length of the process of sapwood formation. Agarwood sapwood can occur when specific pathogens infecting the agarwood-producing trees. The response of agarwood to the pathogen attack is by producing secondary metabolites or resin compounds that cause aromatic fragrance when burned (Sitepu et al., 2011). In the formation of agarwood sapwood induced by microbes such as fungi, it qualitatively produces chemical components such as acetylacetone, benzaldehyde, benzyl acetone, guanine, palustrol, and chromone derivatives. These compounds have a similar composition with agarwood natural chemical compounds (Faizal and Esyanti, 2018). Zhang et al. (2017) showed that chromone compounds and their derivatives are important

components in agarwood sapwood. Isolation of compounds from the solid culture of B. rhodina A13 endophytic fungi in A. Sinensis showed that these fungi were able to produce seven analog compounds 2- (2 phenylethyl) chromoneThe compounds that have been identified based on spectral data of chemical physical characteristics are: 6-hydroxy-7-methoxy-2- (2 phenylethyl) chromone (1), 6,7-dimethoxy-2- (2-phenylethyl) chromone (2) , (5S, 6R, 7S, 8R) -2- (2-phenylethyl) -5,6,7,8-tetrahydrchromone (3), 6-hydroxy-2-(2-phenylethyl) chromone (4), 4 ′ -hydroxy-2- (2-phenylethyl) chromone (5), 6-

methoxy-2-phenethyl-4H-chromen-4-one (6), and 6-methoxy-2- (4′-methoxy-phenethyl) - 4H-chromen-4-one (7).

According to Mega and Phabiola's (2010) research result, the fungus species Fusarium sp and Rhizopus sp. causes the formation of agarwood sapwood in the Gyrinops versteegii plant. Putri et al. (2016) showed that agarwood-producing plants inoculated with mushrooms produced 1.1% higher resin content than non-inoculated plants. Liquid inoculant mixture from Fusarium solani and Rhizopus spp. successfully inoculated Gyrinops versteegi for 16 months which produced agarwood with a resin content of 13.58%. (Mega et al., 2015).

Traditionally in China, the quality of agarwood is determined by resin content,

immersion, odor, method of inoculation, duration of sapwood formed, and the location of sapwood formed (Liu et al., 2017). Furthermore, Nor Azah et al. (2013) said that the usage parameters of color, specific gravity, agarwood formation, and odor are very subjective when classifying the quality of agarwood, the resin content can be used as a guidance in classifying agarwood quality. In Indonesia, agarwood quality classification systems are based on color, weight, and aroma. This method indicates that the current quality of the agarwood welding system is still subjective. Therefore, more objective welding parameters are needed, such as those related to chemical composition and resin content (Pasaribu et al., 2013).

Information about chemical compounds contained in agarwood is important to utilize this product. The utilization of this information is to create product standards based on the chemical composition it contains so the practice of determining the quality of agarwood products more constant, the development of other uses by opening up a possibility of identifying new compounds with new benefits, information on biosynthetic pathways for the possibility of another synthetic compound, the development of compounds in agarwood with biotechnology, and other broad possible developments.

Information and benefits of agarwood sapwood chemical composition could increase community interest in cultivating agarwood-producing trees, so agarwood production will continue to be abundant and bring prosperity to the people who produce it, able to maintain environment security and the diversity of natural resources.

Based on the problem that the chemical components of agarwood from the fungus inoculation not revealed in the Gyrinops versteegii plant, which can create an objective parameter of agarwood quality, the research should be conducted.

MATERIALS AND METHODS

Material (samples) in the form of agarwood (sapwood) from 4 treatments, namely: A (control or wood without fungal inoculation), B (sapwood resulting from inoculation of Fusarium fungus), C (sapwood resulting from Rhizopus fungal inoculation), and D (sapwood resulting from Trichoderma fungal inoculation). The sapwood samples were produced by agarwood-producing trees (Gyrinops versteegii) that had been inoculated for 1 year (12 months) in farmland at Marga Dauhpuri Village, Marga District, Tabanan Regency. The chemicals used are acetone, silica gel (Merck, 60-120 mesh), 60 F silica gel plate (Merck), hexane, and others. The tools used in this study are slep (tools for

making agarwood powder), chisels, hammers, soxhlet flasks, column chromatography, Gas ChromatographyMass Spectrometry (GCMS), rotary evaporators, and others

The method used in this study are extraction, fractionation, and identification is GCMS.

-

1. Manufacture of agarwood powder

The sample of agarwood (sapwood) from each treatment are A (agarwood sample without fungal inoculation (control), B (agarwood sample with Fusarium fungal inoculation), C (agarwood sample with Rhizopus fungal inoculation), D (agarwood sample with Trichoderma fungal inoculation). The four samples were cut to the smallest to ease the grinding process. The four samples should be ground to a 40-60 mesh.

-

2. Extraction and fractionation

A total of 10 g of agarwood powder that has been mashed is extracted using a soxhlet flask. Extraction is carried out with the help of 150 mL of acetone for 3 hours or until the extract in the soxhlet flask has no color. The extraction roots then heated with the help of a water heater at 100 ° C. Next, the extraction results were concentrated with the help of a rotary evaporator until all the solvents have evaporated. The concentrated extract obtained is agarwood resin which has blackish-brown color.

After that, the resin obtained weighed and fractionated by column chromatography. The chromatography column packaged with 20 g silica gel and a hexane solvent. Around 0.5 g of agarwood resin is dissolved by adding a few drops of acetone until all resins have been completely dissolved. Agarwood resin samples were put into the chromatography column, eluted with n-hexane solvent and hexane-EtOAc (ethyl acetate) mixture with variation ratio (9: 1-1: 9) which was the best eluent. After all the solvents are used, the column is eluted with methanol to clean the remaining samples because methanol has a very high polarity. Every 5 ml fraction is collected in a test tube and labeled. Fractionation samples were tested by thin-layer chromatography (TLC) to group the fractions based on their retention rate.

-

3. Identification

The fraction which has the largest weight is used for chemical component analysis using GCMS. The analysis process with GCMS uses the electron attack ionization (EI) method on GC-17A (Shimadzu) gas chromatography which is quenched with MS QP 5050A mass spectrometer; DB-5 ms (J&W) capillary column (silica 30m × 250 μm × 0.25 μm); at column temperature of 50° C (0 minutes) to 290 ° C with temperature rate is increased of

15 ° C / minute; the carrier gas is helium at a fixed pressure of 7.6411 psi.

RESULTS AND DISCUSSION Morphological analysis

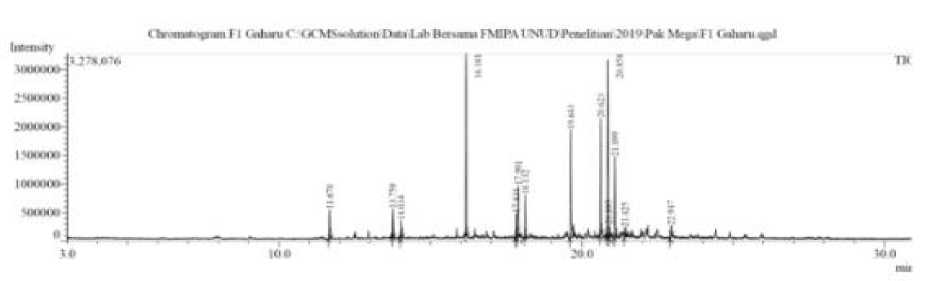

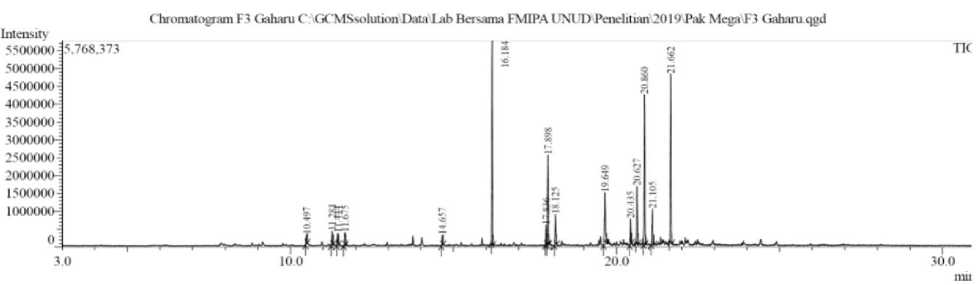

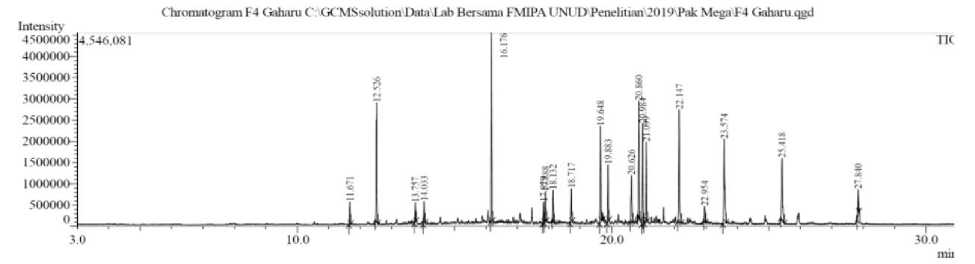

The results of chemical components identification contained in agarwood sapwood from fungi inoculation are presented in Figure 1. Based on the data area in the chromatogram image on the four samples of agarwood sapwood in Figure 1, the abundance of chemical compounds interpreted is presented in Table 1.

The results of the GCMS analysis on four agarwood sapwood samples resulted in the presence of terpene compounds. Terpenoids are compounds composed of isoprene (C5) structure, which are five-carbon chains with branched methyl at carbon number 2 or multiples (Saifudin, 2002). Mastuti (2016) said the terpene compounds are classified based on the number of isoprene units: Monoterpene contains 2 units of C5, Sesquiterpene contains 3 units of C5, Diterpene contains 4 units of C5, triterpene contains 6 units of C5, tetraterpene contains 8 units of C5, and poly terpene contains n C5 units (N> 8 C5 units).

In this study, the variation of a monoterpene, sesquiterpene, and diterpene is obtained. These compounds were found in the retention time range (RT) of 11.67 to 21.43 (Figure 1). Dominant sesquiterpene

found in sapwood with Trichoderma sp. inoculation (D), followed by treatments B and C. Details of the identified sesquiterpene compounds showed in Table 1.

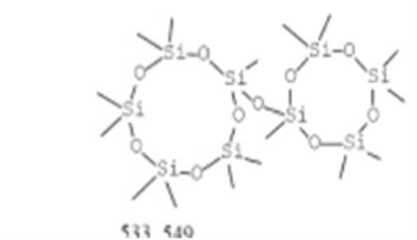

Based on table 1, all agarwood sapwood samples (control and fungi inoculation) have ester chemical components that give aromatic fragrance. These compounds consist of Pentadecanoic acid, 14-methyl-, methyl ester (C17H34O2); Cyclopropane pentanoic acid, 2-undecyl-, methyl ester (C20H38O2); Cyclopropane dodecanoic acid, 2-octyl-, methyl ester (C24H46O2); 9-octadecanoic acid, methyl ester (C19H36O2); Octadecanoic acid, 9.10-dihydroxy-, methyl ester (C19H38O4); Hexanedioic acid, dioctyl ester (C22H42O4). The chemical component of agarwood contains furan compounds and other ester groups that cause fragrance (Pasaribu et al., 2013). There was a difference in abundance on each treatment (Table 1). Also, new compounds discovered namely 2- (2 ', 4', 4 ', 6', 6 ', 8', 8 'Heptamethyltetrasiloxan -2' in sapwood from Trichoderma sp. inoculation with the molecular formula (C16H48O10Si9) and the structure is in the form of a C5 circle with methyl (Fig. 2). Furthermore, Pasaribu et al. (2015) suggested that the presence of a sesquiterpene group in the agarwood quality of kemedangan C, Teri C, kacangan C, and super AB. The aromadendrene compounds found in all quality of agarwood, this

chemical compound suspected as a sign of agarwood. The higher the aromadendrene level, the better the quality of the agarwood.

The most abundant compounds and various compounds found in agarwood from Trichoderma fungi inoculation (12 compounds). It also contains secondary metabolites compound in the form of an ester and non-ester. The ester compound is Hexanedioic acid, dioctyl ester; 11-octadecanoic acid, methyl ester; Cyclopropanedodecanoic acid, 2-octyl-, methyl ester; 9-octadecanoic acid, methyl ester; Octadecanoic acid, 9.10-dihydroxy-, methyl ester; Cyclopropanepentanoic acid, 2-undecyl-, methyl ester; Pentadecanoic acid, 14-methyl-, methyl ester. The non-ester compounds, namely 2-tridecen-I-ol; 2- (2 ', 4', 4 ', 6', 6 ', 8', 8'Heptamethyltetrasiloxan -2 '; 3-Hydroxybutanamide. 8-methoxy-2- (2-. Research results by Nasution et al. (2019) shows that the presence of phenylethyl) chromen-4-one and 7- (benzyloxy) -5-hydroxy-2-methylchromone compounds in agarwood from Gyrinops versteegii in addition to sesquiterpene compounds.

(A)

(B)

(C)

(D)

Fig. 1. Chromatogram of agarwood chemical components from fungal inoculation {F1 (A), F2 (B), F3 (C), F4 (D)}

Table 1. Chemical compounds in agarwood sapwood resulted from fungal inoculation in the Gyrinops versteegii plant

|

Treatment (% area relative) | ||||||

|

No |

Chemical Name |

Retention Time (RT) |

Contro l (A) (%) |

Fusari um (B) (%) |

Rhizo pus © (%) |

Trichod erma (D) (%) |

|

1 |

Dodecanoic acid, methyl ester |

11.67 |

5.37 | |||

|

2 |

2-tridecen-I-ol |

13.76 |

3.01 |

1.54 |

0.66 | |

|

3 |

Pentadecanoic acid, 14-methyl-, methyl ester |

14.04-16,. 8 |

36.3 |

32.11 |

10.08 | |

|

4 |

Cyclopropanepentanoic acid, 2-undecyl-, methyl ester |

17.83-17.90 |

9.82 |

3.65 |

5.68 |

1.68 |

|

5 |

Oktadecanoic acid, methyl ester |

20.63 |

1.59 | |||

|

6 |

9-oktadecanoic acid, methyl ester |

19.64 |

27.65 |

31.36 |

16.7 |

2.29 |

|

7 |

11-oktadecanoic acid, methyl ester |

3.09 | ||||

|

8 |

Oktadekanoic acid, 9.10-dihydroxy-, methyl ester |

20.62 |

8.03 |

2.75 |

4.23 |

1.38 |

|

9 |

Dodecyl acrylate |

20.89 |

1.42 | |||

|

10 |

Cyclopropanedodekanoic acid, 2-octyl-, methyl ester |

21.1 |

6.74 |

4.19 | ||

|

11 |

Cyclohexane, 2-ethyl-4methoxy- |

21.43 |

0.77 | |||

|

12 |

Eicosanoic acid, methyl ester |

16.19 |

47.71 | |||

|

13 |

9,12 octadecadienoic acid, methyl ester |

17.89 |

4.35 |

2.07 | ||

|

14 |

Hexanedioic acid, dioctyl ester |

20.44 |

2.67 |

2.38 |

5.42 | |

|

15 |

Trans-caryophyllene |

10.49 |

1.98 | |||

|

16 |

Germacrene D |

11.28 |

1.47 | |||

|

17 |

Farnesol |

11.45 |

1.72 | |||

|

18 |

Benzyl benzoate |

14.66 |

1.48 | |||

|

19 |

Di-n-octyl phthalate |

21.66 |

22.41 | |||

|

20 |

3-Hydroxybutanamide |

22.96 |

1.79 | |||

|

21 |

2-(2’,4’,4’,6’,6’,8’,8’Heptamethyl tetrasiloxan -2’ |

18.72-19.88 |

12.2 | |||

Fig. 2. Molecular formulas C16H48O10Si9 ) and chemical structures 2- (2 ’, 4’, 4 ’, 6’, 6 ’, 8’, 8 ’

Heptamethyltetrasiloxan -2 ’

CONCLUSION

Chemical components contained in agarwood from inoculation results mainly in the form of ester compounds.

The highest types of compounds and abundance found in agarwood with Trichoderma fungus inoculation in the form of esters, namely Hexanedioic acid, dioctyl ester; 11-octadecanoic acid, methyl ester; Cyclopropanedodecanoic acid, 2-octyl-, methyl ester; 9-octadecanoic acid, methyl ester; Octadecanoic acid, 9.10-dihydroxy-, methyl ester; Cyclopropanepentanoic acid, 2-undecyl-, methyl ester; Pentadecanoic acid, 14-methyl-, methyl ester; and non-ester compounds, namely 2-tridecen-I-ol; 2- (2 ', 4', 4 ', 6', 6 ', 8', 8 'Heptamethyltetrasiloxan -2'; 3-Hydroxybutanamide. 8-methoxy-2- (2.

ACKNOWLAGEMENTS

Thank you very much to Rector of Udayana University for the financial

assistance and the permits, so this research finished.

REFERENCES

Akter, S., Tanvir Islam, Md., Mohd Zulkefeli, and Islam Khan, S. 2013.. Agarwood Production- A Multidisciplinary Field to be Explored in Bangladesh. International Journal of

Pharmaceutical and Life Sciences. P. 22-32.

Faizal, A. dan Esyanti, R.R. 2018. Interaksi Mikroba dengan Pohon Penghasil Gaharu Genus Aquilaria. Dalam Budi, S.W; Hidayat, A dan Turjaman, M. Bioprospek Mikroba Hutan Tropis Indonesia. Penerbit IPB Press, Bogor, Indonesia.

Liu Y.Y, J.h Wei, Z.-h Gao, Z.Z., J-c Lyu. 2017. A Review of Quality Assessment and Grading for Agarwood. Chinese Herbal Medicines, 2017, 9(1): 22-30.

Mastuti, R. 2016. Metabolit Sekunder dan Pertahanan Tumbuhan. Modul 3 Fisiologi Tumbuhan. Jurrusan Biologi, FMIPA. Unibraw. Malang. 17 hal.

Mega, I M. dan Phabiola, T. A. 2010. Isolasi Jamur Pembentuk Gubal Gaharu Pada Tanaman Gyrinops Versteegii di Kecamatan Pupuan Kabupaten Tabanan. Agritrop Vol. 29, No. 4, Desember 2010. Denpasar. Hal. 189198.

Mega, I M., Suanda, D.K., Kasniari, D.N. and Susrama, I G.K. 2015. Agarwood Producing

Fungal Inoculant Formulation in Ketimunan Tree (Gyrinops versteegii DOMKE). International Journal of Bioscience and Biotechnology, Vol. III No. 1, September 2015. p. 22-27.

Nasution, A.A; Siregar, U.J.; Miftahudin; and Turjaman, M. 2019. Identification of chemical

compounds in agarwood-producing species Aquilaria malaccensis and Gyrinops

versteegii. J. For. Res.

https://doi.org/10.1007/s11676-018-00875-9.

Nor Azah, MA., Saidatul Husni, Mailina,S., J., Sahrim, I. J., Abdul Majid, J., and Mohd Faridz, Z. 2013. Classificatin of Agarwood (Gaharu) by Resin Content. Journal of Tropical Forest Science. Vol. 25 No. 2. Pp. 213-219.

Pasaribu, G., Waluyo, T.K. & Pari, G. 2013. Analisis Komponen Kimia Beberapa Kualitas Gaharu dengan Kromatografi Gas Spektrometri Massa. J. Penelitian Hasil Hutan, Vol. 31, No.3. hal. 181185.

Pasaribu , G., T. K.Waluyo and G. Pari. 2015. Analysis Of Chemical Compounds Distinguisher For Agarwood Qualities. Indonesian Journal of Forestry Research Vol. 2, No. 1, April 2015, 17.

Putri, N., Karlinasar, L., M. Turjaman, M., Wahyudi, I. and Nandika, D. 2017. Evaluation of incense-resinous wood formation in agarwood (Aquilaria malacensis Lam) using sonic tomography. Agriculture and Natural Resources 51 (2017): 84-90.

Saifudin, A. 2014. Senyawa Alam Metabolisme Sekunder Teori, Konsep dan Teknik Pemurnian. Penerbit Deepublish. Yogyakarta. 546 hal.

Santosa, H. 2009. Konservasi dan Pemanfaatan Gaharu. Disampaikan dalam Seminar Nasional I Gaharu. Bogor.

Sen, S., Dehingia, M., Talukdar N.C., dan Khan, M. 2017. Chemometric analysis reveals links in the formation of fragrant biomolecules during

agarwood (Aquilaria malaccensis) and fungal interactions. Scientific Reports. 7: 44406.

Sitepu, I. R., Santoso, E., & Turjaman, M. 2011. Identification of Eaglewood (Gaharu) Tree

Species Susceptibility. Technical Report No.

1. R & D Centre for Forest Conservation and Rehabilitation

Forestry Research and Development Agency (FORDA) Ministry of Forestry Indonesia

Waluyo, T.K dan F. Anwar. 2012. Identifikasi Komponen Kimia Empat Kelas Mutu Gaharu (Kacangan A, Teri B, Kamedangan A Dan Kamedangan B). Jurnal Penelitian Hasil Hutan Vol. 30 No. 4, Desember 2012: 291-300.

FACULTY OF AGRICULTURE, UDAYANA UNIVERSITY • 49

Discussion and feedback