Preliminary Study of Swiftlet House Transition for the Cultivation of Grey Oyster Mushrooms

on

INTERNATIONAL JOURNAL OF BIOSCIENCES AND BIOTECHNOLOGY eISSN: 2655-9994 pISSN: 2303-3371

Vol. 11 No. 1 September 2023

Preliminary Study of Swiftlet House Transition for the

Cultivation of Grey Oyster Mushrooms in Malaysia

Muhammad Fariz Hidayat1, Aisar Novita1*, Khairul Asfamawi Khulidin2, Kamarul Zaman Ahmad3, Nurasmaliza Mohd Akhir3, Nurhidayah Fazil3, Mohd Afif Shahbuddin3, Nur Hafizoh Halim4 and Hadriman Khair1

1Faculty of Agriculture, Universitas Medan Area, Jalan Kolam Nomor 1 Medan Estate / Jalan Gedung PBSI, Medan, Sumatera Utara, 20223, Indonesia

-

2Soil Science, Water and Fertilizer Research Center, MARDI Headquarters, Persiaran MARDI-UPM, 43400

Serdang, Selangor, Malaysia

-

3Technology Transfer and Entrepreneur Development, MARDI Kedah Office, Jalan Kuala Kedah, 05710 Alor

Setar, Kedah, Malaysia

-

4Technology Transfer and Entrepreneur Development, MARDI Pendang, Pendang Post Office, 06707 Pendang, Kedah, Malaysia

-

*Correspondence email: aisarnovita@umsu.ac.id

Received: 07-23-2023 Revised: 11-30-2023 Accepted: 12-29-2023

Citation: Hidayat, M.F. Novita, A., Khulidin, K.A., Ahmad, K.Z., Akhir, N.M., Fazil, N. et al. (2023). Preliminary Study of Swiftlet House Transition for the Cultivation of Grey Oyster Mushrooms. International Journal of Biosciences and Biotechnology, 11 (1): 62-70. https://doi.org/10.24843/IJBB.2023.v11.i01.p09.

Abstract. A variety of design and sizes of mushroom houses are used for the cultivation of grey oyster mushrooms (Pleurotus pulmonaris). A few improvements and a little expense given a good value of impact on mushrooms yield. The method of implementing this activity includes several comparisons regarding the efficiency of farmers' mushroom houses, mushroom houses from swallow houses and mushroom houses managed by Malaysian Agricultural Research and Development Institute (MARDI). This research was located in Kedah dan Serdang, Selangor, Malaysia. Research activities include (1) field survey, (2) making requirements for mushroom cultivation and installation of the tools for mushroom cultivation, (3) field observation, (4) data collection and analysis of capital, effectiveness and best profits. A total of 119.3 g per bag of grey oyster media produced in the swiftlet house, Sg. Petani, Kedah compared to 149.1 g per media bag in the Control Environmental Mushroom House (CEMH) MARDI Headquater, Serdang, Selangor. Although, mushroom yield is higher CEMH than swiftlet house but CEMH operating cost is bigger do the high electricity consumption However, there was no significant difference in the yield of mushrooms in the swiftlet house (119.3 g per media bag) with the DANA project mushroom house, MARDI Kedah Office, Alor Setar, Kedah (115.9 g per media bag).

Keywords: Swiftlet house, grey oyster mushroom cultivation, growth, parameter, mushroom grower.

A variety of design and sizes of mushroom houses are used for the cultivation of grey oyster mushrooms (Pleurotus pulmonaris). No specific design of the mushroom house as well as the building materials used. Bamboo houses (bamboo), mushroom cabins (metal deck), mushroom houses (wood) and canopy mushroom houses, RCK

Central Laboratory for Genetic Resource and Molecular Biology

Faculty of Agriculture Udayana University

https://ojs.unud.ac.id/index.php/jbb/index

(canvas) are commonly used among local mushroom growers. The use of black netting (70%) as a mushroom house wall is strongly encouraged instead of brick or metal deck. This is due to enable the movement of air in and out to maintain an appropriate temperature and relative humidity or mushroom growth. Figure 1 shows types of mushroom houses used among local grey oyster mushroom grower.

Figure 1. Types of Mushroom Houses Used Among Local Grey Oyster Mushroom Grower

The growth parameters of grey oyster mushrooms are highly dependent on temperature, 28 ± 2°C and relative humidity, 80 ± 10% RH (relative humidity). In addition, other parameters such as air flow, 5-40 cm/s carbon dioxide concentration, 800-1500 ppm and light intensity, 500-2000 lux are also influence mushroom growth. Due to high maintenance costs, only temperature and relative humidity parameters are used as a reference among local grower.

The CEMH is an IoT (Internet of Things) integrated building that can regulate environmental factors for mushroom growth. Furthermore, CEMH can control and manipulate environmental parameters to suit the growth of mushrooms. Button mushroom (Agaricus bisporus) and King oyster mushroom (Pleurotus erygnii) are among the mushrooms that require a controlled agro-climate environment for their growth. Figure 2 shows CEMH and control of temperature and relative humidity by automatic water sprinkle.

Figure 2. Control Environmental Mushroom House (CEMH) (left) and Control of Temperature and Relative Humidity by Automatic Water Sprinkle (right)

The decline in cave yields (harvesting of swiftlet nests from caves) led to initiatives to provide artificial premises through the construction of buildings devoted to attracting nesting swiftlets. A furthermore study should also be carried out to identify the factors that can attract swiftlets to nest in the houses built. However, one of the swiftlet houses in Sungai Petani, Kedah found the absence of swiftlet nests for a long time of period. As result, this swiftlet house become unmanaged and abandoned. Thus, cultivation of grey oyster mushrooms seems as the potential economic activity that used the swiftlet house as mushroom growth house.

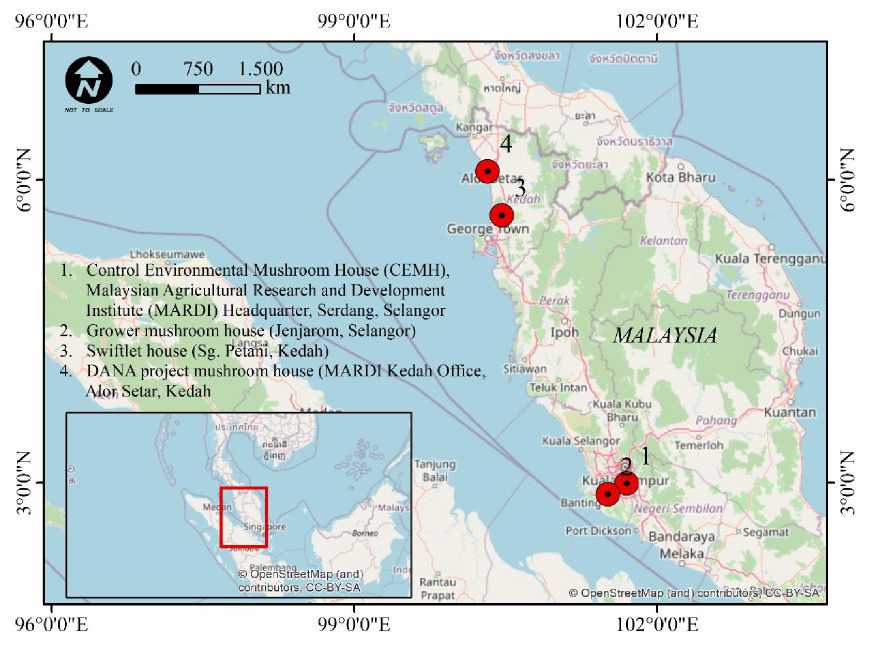

This research was conducted in Selangor dan Kedah, Malaysia. The locations, as shown in Figure 3, are:

-

1. Control Environmental Mushroom House (CEMH), Malaysian Agricultural Research and Development

Institute (MARDI) Headquarter, Serdang, Selangor

-

2. Grower mushroom house (Jenjarom, Selangor)

-

3. Swiftlet house (Sg. Petani, Kedah)

-

4. DANA project mushroom house (MARDI Kedah Office, Alor Setar, Kedah)

Hialrtru

iaκ5oacia

Kangar

Kdta Bharu

George

Rerak

Ipoh

AdALAYSlA

Chukai

Kuantan

Pahang'

Kuala Selangbr

' BarninJ

Negeri Sembilan

Terenggonu \

Oungun

Sitiawan

Teluk Intan

^‰~ Kuala Kubu

Bharu

Kelontan \

Kuala Terenggani

96o0,0"E

99o0'0"E

102o0'0"E

96o0,0"E

99o0'0"E

102o0,0"E

io KioOocnu

1.

Temerloh

Malay's

Sing; lore

© OpenStreetMap (and) contributors.1'CC-BY-SA

2.

3.

4.

Tanjung Ba Iai

© O,pe∩⅛tr%etMap (and) contributors. CC-BY-SA

Rantau Prapat

750 1.500

■ i km

IiaEiS . fi>∏O

PortD1Cksonc Bancfaraya » Segamat Melaka.

Lhokseumawe

Control Environmental Mushroom House (CEMH), Malaysian Agricultural Research and Development Institute (MARDl) Headquarter, Serdang, Selangor Growermushroom house (Jenjarom, Selangor) Swiftlet house (Sg. Pelani, Kedah)

DANA project mushroom house (MARD! Kedah Office, Alor Setar, Kedah

Figure 3. Research Location

In this research, the tools and materials used include literature on oyster mushroom cultivation businesses, oyster mushroom isolation equipment and initial oyster mushroom seeds. Apart from that, sterilization equipment is needed, both tools and media sterilization, baglog, and oyster mushroom cultivation areas. The technique used to foster an entrepreneurial spirit in this unit is Entrepreneurship Capacity Building (ECB) to initiate and improve entrepreneurial abilities through empowerment and mentoring. The technical method used in this activity is to observe/compare which is best in terms of capital, effectiveness and profits in cultivating oyster mushrooms with different cultivation sites in terms of management from the community, entrepreneurs and Malaysian Agricultural Research and Development Institute (MARDI).

The method of implementing this activity includes several comparisons regarding the efficiency of farmers' mushroom houses, mushroom houses from swallow houses and mushroom houses managed by MARDI. Everything is carried out in stages consisting of preparation, implementation and mentoring stages. Preparatory activities include (1) field survey, (2) making requirements for mushroom cultivation and installing the tools needed for mushroom cultivation in accordance with the SOP, (3) observation by directly inspecting the field, (4) data collection and drawing conclusions in terms of capital, effectiveness and best profits.

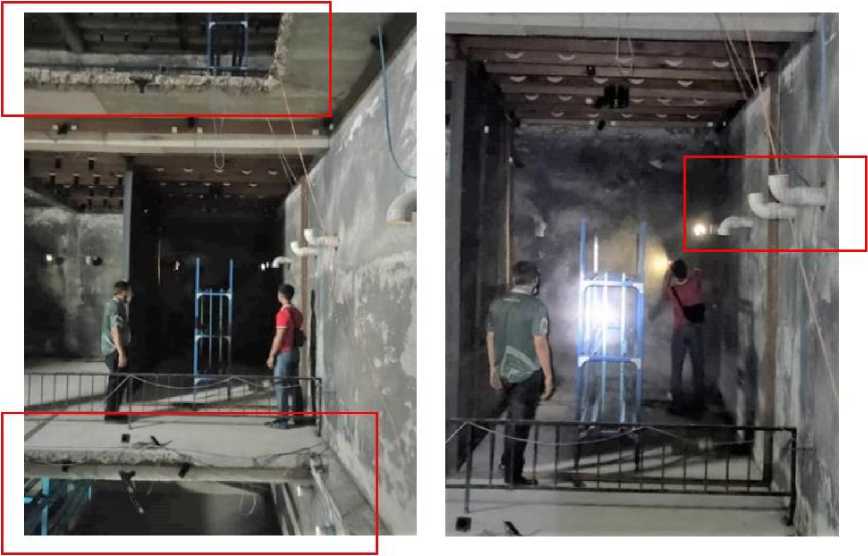

Planting mushrooms only needs to meet the growth criteria for mushrooms, namely temperature and humidity. The requirements of using swiftlet houses for the cultivation of grey oyster mushrooms, as shown in Figure 4 and Figure 5, are:

-

1. Has good airflow as there are large openings for the passage of swiftlets and air ducts in the walls

-

2. Has recorded temperature between 27 - 30°C and relative humidity percentage, (RH) 70% and above

-

3. Has protected from direct sunlight and rain (building)

-

4. Has protected from the threat of pests and small animals (building)

Figure 4. Large Opening in Certain Floor (passage of swiftlets) (left) and Air Ducts (right)

The internal of the swiftlet house needs to be examined in the aspect of hygiene. Fungal growth on wall surfaces and animal faeces should be removed or washed (sanitised) with a solution of chlorine or disinfectant (Dettol). The presence of small animals is also monitored especially rats, squirrels or birds by imposing a livetraps. This measure is intended to prevent contamination or damage to the media bags and fresh mushrooms. Shelves for placing media bags are provided according to the size and quantity of media bags. The use of ‘c-channel’ (0.75mm) blue iron material to make media bag racks is highly recommended to prevent decay and fungal growth. Figure 6 shows ‘c-channel blue’ iron (0.75mm) was used to make the media bag placement rack.

Figure 5. Consistent Temperature and Humidity Readings in the Morning (left) and Afternoon (right)

Figure 6: ‘C-channel Blue’ iron (0.75mm) was Used to Make the Media Bag Placement Rack.

The sterile media bags are arranged horizontally on a rack for an incubation period. After 60 days of incubation, the lid of the media bag is opened to encourage mushroom growth. A humidifier is used to increase the percentage of relative humidity. There is various tool to control the temperature of the mushroom house either using water spray (sprinkle) or water vapor spray (mist). The position of the tool is important to ensure an appropriate temperature surrounding obtained. To prevent deteriorate of mushroom and contamination of media bag, avoid from direct water spray. Figure 7 shows humidifier optimised the temperature and humidity on the surrounding area. Oyster mushrooms are a type of wood mushroom that has a higher nutritional content compared to other types of wood mushrooms. every 100 grams of oyster mushrooms contains 19-35% protein with 9 kinds of amino acids; 1.7-2.2% fat consists of 72% unsaturated fatty acids. Meanwhile, mushroom carbohydrates consist of thiamine, riboflavin and niacin, which are the main B vitamins in oyster mushrooms, apart from vitamins D and C, the minerals consist of K, P, Na, Ca, Mg, Zn, Fe, Mn, Co and Pb.

Figure 8 shows water sprinkle and water vapor spray in a mushroom house. Drought tolerance is the ability of plant tissue to maintain plant physiological and metabolic activities if water potential decreases. The benefits of water for plants as a solvent and medium for transporting plant nutrients and forming new compounds. If there is a lack of water, it will inhibit plant growth such as roots and leaves so that the plants become stunted. For plants, water is a very important factor for survival because it accounts for approximately 50% of the weight of the stem, 50-70% of the weight of the leaves and 70-90% of the weight of the flowers.

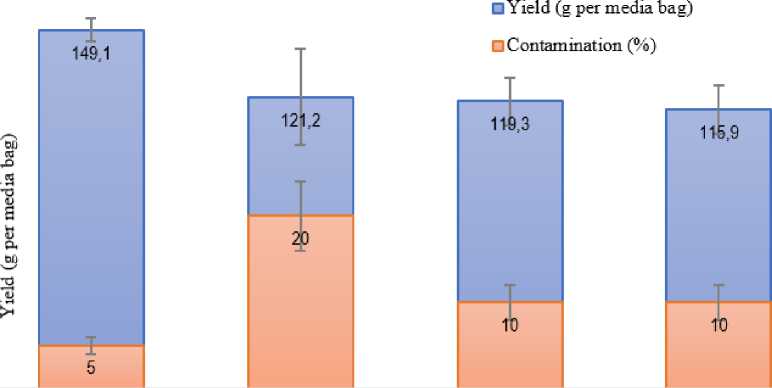

Planting mushrooms only needs to meet the growth criteria for mushrooms, namely temperature and humidity. Although various types of mushroom houses were built. Cultivating oyster mushrooms requires special treatment because oyster mushrooms are easily attacked by disease. Fungal growth will be hampered if temperature and humidity are not controlled properly because temperature and inertia can affect fungal growth. Oyster mushroom growth is usually optimal at a temperature of around 22-28°C and humidity of around 70-90%. We often encounter this problem in oyster mushroom cultivation. Therefore, it is very important to control the temperature and humidity of the oyster mushroom cultivation room. Figure 9 shows comparison of yield (g per media bag) by type of mushroom house.

Figure 7. Humidifier Optimised The Temperature and Humidity in Tthe Surrounding Area.

Figure 8. Water Sprinkle (top) and Water Vapor Spray (bottom) in a Mushroom House.

Figure 9 shows a total of 119.3 g per bag of grey oyster media produced in the swiftlet house compared to 149.1 g per media bag in the CEMH. Although, mushroom yield is higher CEMH than swiftlet house but CEMH high in operating cost (high electricity consumption). However, there was no significant difference in the yield of mushrooms in the swiftlet house (119.3 g per media bag) with the DANA project mushroom house (115.9 g per media bag). In practice, the swiftlet houses to grey oyster mushroom growth can be implemented with minor modification.

The transition of buildings or spaces must involve the needs of mushroom growth before the modification is carried out. This is due to avoid excessive modification, increased costs and time. The guideline for ensure the needs of mushroom growth are:

-

1. Ensure that the premises / building / space meets the requirement of mushroom growth parameters such as temperature (°C) and relative humidity (%RH)

-

2. Ensure that the premises / building / space meet hygiene standards – to avoid contamination / damage to media bags.

-

3. Ensure that the premises / building / space meet work standards – to facilitate work to be carried out.

-

4. Once each guideline is identified, the modifications or changes need to be planned to avoid wastage in

terms of cost, manpower and time.

Green fungus (Trichoderma spp.) and orange or orange fungus (Neurospora spp.) are among the fungi that often attack the mushroom medium bag. The presence of green fungus is caused by the use of contaminated or damaged seeds while the presence of orange or orange fungus is due to the incomplete steaming time of the medium bag. Both of these fungal pests can be avoided by practicing the standard procedure that has been established for the preparation of mushroom medium bags. Figure 10 shows attack of green fungus (Tricoderma spp.) and orange fungus (Neurospora spp.) on medium bags

IBD

UD 120

100

ao

60

40

20

O

EtiviroiimentCoiitrol Growerniushrootiihousez SwiftletHousezSg. DANAprojecttnushrooiii MushroomHouse JetijaromzSelaiisor PetanizKedah housez MARDI Kedah

(CEMH)z MARDI Officez Alor Setarz Kedah

Headquarterz Serdangz

Selangor

Figure 9. Comparison of Yield (g per media bag) by Type of Mushroom House.

Figure 10. Attack of Green Fungus (Tricoderma spp.) (left) and Orange Fungus (Neurospora spp.) on Medium Bags (right)

Standard operating procedures for the conversion of premises, buildings or spaces to be used as gray oyster mushroom cultivation houses need to be developed to help mushroom entrepreneurs. In addition, the use of SOPs can avoid excessive use and increases in capital. However, each use must take into account the following fungus growth requirements:

-

1. Ensure that premises, buildings or spaces meet mushroom growth parameter standards by conducting

relative humidity and temperature tests at certain times.

-

2. Ensure that the premise, building or space complies with cleanliness aspects to avoid contamination or

damage to the media bag.

-

3. Ensure that premises, buildings or spaces comply with work standards to facilitate work execution (work

movement).

A total of 119.3 g per bag of grey oyster media produced in the swiftlet house, Sg. Petani, Kedah compared to 149.1 g per media bag in the CEMH, MARDI Headquater, Serdang, Selangor. Although, mushroom yield is higher CEMH than swiftlet house but CEMH operating cost is bigger do the high electricity consumption However, there was no significant difference in the yield of mushrooms in the swiftlet house (119.3 g per media bag) with the DANA project mushroom house, MARDI Kedah Office, Alor Setar, Kedah (115.9 g per media bag).

No significant different yield of grey oyster mushroom compared either on swiftlet house or DANA project mushroom house. Minor modification of swiftlet house should be done to ensure meet the parameter of mushroom growth. Indirectly, transition of swiftlet house into mushroom house gives a hope to transform the activity from loss to gain.

Author Contributions

Conceptualization, MH, AN.; methodology, KK, KA.; validation, NA.; formal analysis, NF, MS.; investigation, NH, HK.; resources, MH, AN.; data curation, NA.; writing—original draft preparation, MH, AN.; writing—review and editing, MH, AN; visualization, HK.; supervision, AN..; project administration AN.; funding acquisition. All authors have read and agreed to the published version of the manuscript.

Informed Consent Statement

Not applicable.

Data Availability

Not applicable.

Acknowledgements

Conflicts of Interest

The authors declare no conflict of interest

References

Alridiwirsah, A., Risnawati, R dan Novita, A. (2019). Pemanfaatan Lahan Sempit Dengan Budidaya Jamur Tiram Untuk Memenuhi Kebutuhan Sayuran Panti Asuhan Putera Muhammadiyah Cabang Medan. Jurnal Prodikmas Hasil Pengabdian Kepada Masyarakat, 3(2), 52-58.

Khairul Asfamawi, K (2020). Huluan ke hiliran cendawan jana pendapatan berantai. Agromedia Bil. 58: 84 – 85.

Khairul Asfamawi, K., Ganisan, K., Mohd Hafiz Fikri, H., Ahmad Fuad, B., Mohd Hafiz, M. A. T., Mohd Azmirredzuan, S. dan Syaliyana, K. (2020). Benih cendawan cecair: Kaedah pengkulturan baharu untuk industri cendawan tempatan. Buletin Teknologi MARDI 18: 65 – 73

Khairul Asfamawi, K., Ganisan, K., Rosli, M. A. dan Syaliyana, K. (2020). Benih cendawan pelet kayu: Kaedah alternatif penginokulasian cendawan. Buletin Teknologi MARDI 18: 57 – 63.

Khairul Asfamawi, K., Ganisan, K., Rosli, M.A. dan Syaliyana, K. (2019). Comparative study of ‘stick and stay’ pellet spawn on selected edible mushroom. Southeast Asia Vegetable Symposium, Hatten Hotel, Melaka. 9 – 11th July

Khairul Asfamawi, K., Ganisan, K., Ten, S. T dan Ahmad Fuad, B (2020). Teknologi MARDI berasaskan cendawan : Impak terhadap pengusaha cendawan tempatan. Agromedia Bil. 58: 80 – 82.

Khairul, A.K., Aminuddin, H., Yaseer Suhaimi, M., Mohamad, A.M. dan Hassan, W. (2012). Manual teknologi penanaman cendawan tiram kelabu. MARDI. ISBN 978-967-936-607-5.

Mohd. Rashid Rabu, Ahmad Zairy Zainol Abidin dan Mohd Syauqi Nazmi (2013). Prospek dan cabaran industri sarang burung walit negara. Buletin Teknologi MARDI, Bil. 3: 57 – 69

Parlindungan, Abdul Karim. (2003). Karakteristik pertumbuhan dan produksi jamur tiram (Pleorotus ostreatus) dan jamur tiram kelabu (Pleurotus sajor Caju) pada baglog alang-alang. Jurnal Natur Indonesia, 5(2): 152-156.

Risnawati, R., Alridiwirsah, A dan Yusuf, M. (2021). Penggunaan Teknologi Mantis Terhadap Pertumbuhan dan Produksi Jamur Tiram Di Desa Hamparan Perak. Jurnal Prodikmas Hasil Pengabdian Kepada Masyarakat, 4(1), 82-88.

Ten Seng Teik, Ganisan Krishnen, Khairul Asfamawi Khulidin, Muhd Akhtar Mohamad Tahir, Mohamad Hafiz Hashim, Syaliyana Khairudin (2021). Automated controlled environment mushroom house. Advance in Agricultural and Food Research Journal. Vol. 2 (2): 1 – 13.

Wan Khairy, W. I., Munirah, A. R., Nur Fatihah Nabilah, A. J and Mohd Rafi, Y (2021). Pest disturbance in edible bird nest swiflet house. Annals of the Romanian Society for Cell Biology. Vol. 25 (1): 3081 - 3085.

70

Discussion and feedback