ECOLOGICAL APPROACH ON SANITATION: COMPOSTING OF HUMAN EXCRETA USING BIOTOILET WITH LIGNOCELLULOSES WASTE MATERIAL AS MATRIX

on

Jovita Tri Astuti, dkk. : Ecological Approach On Sanitation : Composting Of Human Excreta

ECOLOGICAL APPROACH ON SANITATION:

COMPOSTING OF HUMAN EXCRETA USING BIOTOILET WITH LIGNOCELLULOSES WASTE MATERIAL AS MATRIX

Jovita Tri Astuti1)*, Dewi Nilawati1), Neni Sintawardani1)

1Environmental Working Group, Research Center for Chemistry Indonesian Institute of Sciences (LIPI), Jalan Cisitu-Sangkuriang, Bandung 40135 *Email: jtri001@lipi.go.id

Abstract

This study was aimed to evaluate the characteristic and prospect of lignocelluloses waste material, i.e. mixtured wood sawdust as matrix in composting human excreta using Biotoilet. Initially, 26.4 kg mixtured wood sawdust (+4/-32 mesh) moisture 11.84% was filled into Biotoilet chamber, and added with 20L tap water to achieve ±50% moisture. Mixer in Biotoilet was adjusted to run-on intermittently with interval 15 min, each for 2 min, i.e. 1 min to clockwise and counter-clockwise, respectively. Exhaust fan with flow rate of 0.04m3.sec-1 was operated continuously to ensure proper aeration. Human excreta were loaded daily to Biotoilet chamber for 90 days which would be composted. Data showed that temperature of composting system was 25.70-43.67oC. Moisture was 22.27-53.20% and pH 6.20-7.00. C/N ratio composted residual sawdust was 25:1. Ash, N, P, and K content were 11.78; 1.78; 0.85; and 0.95%, respectively. Bad odor was not created during composting. It was concluded mixtured wood sawdust could be used as matrix for composting human excreta. The compost could be categorized into Class-A that safe for food and non-food plant. Application of mixture wood sawdust as matrix in Biotoilet for composting human excreta could improve sanitation, prevent water degradation, at once increase soil quality for agricultural.

Keywords: biotoilet, composting, human excreta, lignocelluloses waste, matrix, sanitation.

Abstrak

Penelitian bertujuan untuk mengevaluasi karakteristik dan prospek limbah lignoselulosa berupa serbuk gergaji kayu campuran sebagai bahan matrik dalam komposting ekskresi manusia menggunakan Biotoilet. Sebanyak 26.4 kg serbuk kayu (4-32mesh) dengan kadar air 11.84% dimasukkan ke reaktor Biotoilet, lalu ditambahkan 20 L air untuk mencapai kadar air ±50%. Mixer yang ada di reaktor Biotoilet dioperasikan secara berkala dengan interval waktu 15 menit, masing-masing selama 2 menit, yaitu 1 menit searah dan 1 menit berlawanan arah jarum jam. Kipas dengan kecepatan 0.04m3.sec-1 dijalankan kontinyu agar kondisi tetap aerobik. Eksresi manusia dimasukkan setiap hari selama 90 hari untuk dibuat kompos. Data menunjukkan suhu selama proses komposting berkisar 25.70-43.67oC, kadar air 22.27-53.20%, dan pH 6.207.00. Kompos yang dihasilkan memiliki nilai C/N ratio 25:1. Sedangkan kadar abu, N, P dan K masing-masing sebesar 11.78; 1.78; 0.85 dan 0.95%. Tidak ada bau busuk selama komposting. Dapat disimpulkan serbuk kayu campuran dapat digunakan sebagai matrik dalam komposting ekskresi manusia. Kompos yang dihasilkan termasuk kategori klas-A dan aman untuk tanaman non-pangan maupun pangan. Penggunaan serbuk kayu campuran sebagai matrik dalam Biotoilet untuk composting ekskresi manusia dapat memperbaiki sanitasi, mencegah degradasi air dan lahan pertanian.

Kata Kunci: biotoilet, eksresi manusia, komposting, limbah lignoselulosa, matrik, sanitasi.

Urban areas in developing country often lack adequate sanitation services, such as available water, space, and infrastructure due to rapidly population growing. The previous study reported that 45% of Indonesian people are living without easily accessible of private and safe place to urinate and defecate. Data also presented 3.4.106kg.d-1 of feces and 34.103m3.d-1 urine are released to water bodies and caused polluting substances, which covered of 409.103; 74.103; 19.103; and 556.103tons.year-1of BOD; N; P and TSS, respectively (WSP, 2008).

Survey in Kiaracondong sub district, Bandung city, Indonesia showed that water usage for defecation is high, i.e. ± 10L in average, both for cleaning the body and flushing of toilet bowl. For defecation, 68% of people used tap water from Municipal Water Supply and 32% used well water. In some cases, people must buy tap water just for defecation. Morover, due to limited of private toilet ownership, some people defecated at public toilets and discharged human excreta directly into water bodies (Astuti and Sintawardani, 2006). Meanwhile, as described in Millennium Development Goals, indicator of sanitation now is focused on availability of private and safe disposal human excreta. (WHO, 2006).

Ecological Sanitation (Ecosan) concept is promoted to solve the problems of water and sanitation. The basic principle of Ecosan is the loop between sanitation, water resources, and agriculture. It is a new holistic approach to reduce health risk of sanitation, prevent water pollution and improve soil quality. In this concept, new paradigm was introduced that human excreta now is recognized not as a waste, but as a resource that should be recycled and reused (Langergraber and Muellegger, 2005). The statement of the previous researcher should be noticed that environmental biotechnology is to be a key area which has greatly impacted various tecnologies based on the application of biological processes for environmental protection and resources conservation. Its application cover of a wide range of which leading to protect and remediate of the environmental components, including of soil bioremediation, wastewater biotreatment and solid waste biotreatment (Jhamaria and Yadav, 2014).

Biotoilet is a composting toilet. It has been developed and promoted as a new technology of

sanitation. It would be an alternative to solve a sanitation problem in area with inadequate sewage disposal and limit of water. By this new system a sewage infrastructure can be replaced and water usage can be reduced. Biotoilet system consists of composting chamber which is equipped with mixer, heater and exhaust fan. Due to optimize the composting process, the bukly agent is required as artificial soil matrix for Biotoilet. In process, human excreta would be mixed with matrix material in the composting chamber. Then, the organic compounds of human excreta would be degraded by aerobic bacteria resulting carbon dioxide (CO2) and water (H2O) which will be released to atmosphere. Meanwhile, the mineralized products, such as N, P, and K would be remained in sawdust matrix in composting chamber. Similar to solids obtained from traditional wastewater treatment, solid or residual from composting toilet can be used as fertilizer (Funamizu, 2006).

Matrix materials have low moisture content and apparent density, which provide to optimize of free air space and regulate water content of waste that would be composted. C/N ratio of matrix is high that can make substrate to achieve an appropriate of C/N ratio in composting (Iqbal et al., 2010; Banegas et al., 2007). C/N ratio of human excreta generally is low (5:1), meanwhile ideal level for composting is 15:1-30:1 (Eftoda and McCartney, 2004).

Principally, all of lignocelluloses waste from agricultural and agro-forestry could be used as matrix in Biotoilet. Some have been studied as matrix for composting human excreta, i.e. corn stalk (Sheng et al., 2005); Albizzia sawdust (Triastuti et al., 2008); peanut shell and rice husk (Iqbal et al., 2010); and sugar mill wastes (Saranraj and Stella, 2014).

In Indonesia, lignocelluloses waste materials is produced abundantly and have not utilized optimally yet. Once is wood sawdust, a waste from the sawmill industries. Practically, separation of wood sawdust based on its kind of wood is not common in Indonesia. As the result, the sawdust will be obtained in the form of a mixture from some kinds of woods, both of hard and soft wood. This study was aimed to evaluate the characteristic and propsect of lignocelluloses waste material from sawmill industry as matrix for composting of human excreta, simultaneously to introduce Biotoilet to community

as an alternative to solve a problem in area with inadequate sewage disposal and limit of water.

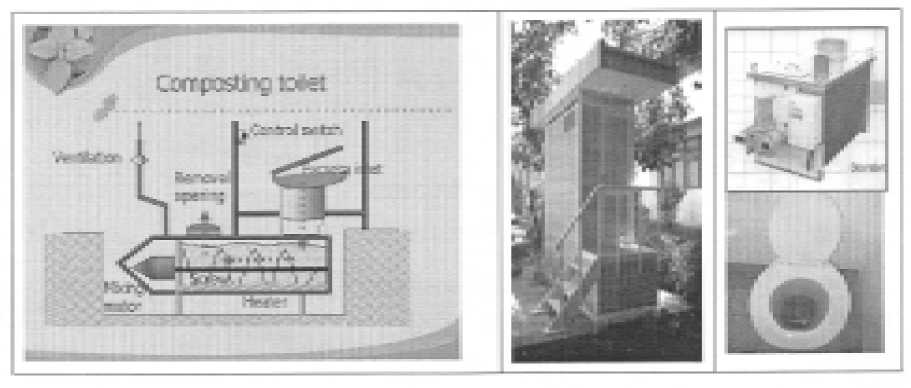

Lignocelluloses waste material, i.e. mixtured wood sawdust from local a sawmill industry was used as matrix in study. Before using, it was air dried and sieved in a series of sieves (32 mesh at bottom and 4 mesh at the upper), to obtain a homogen particle size. Sawdust particles that passed in 4 mesh and retained on 32 mesh sieves (+4/-32) is used in study. Meanwhile, Biotoilet Model Biolux S-15 (Seiwa Denko Co. Ltd, Japan) is used as composter for human excreta (Table 1). The schematic process, composting toilet, room building for defecation and urination with Biotoilet reactor and closet bowl inside that used in study was illustrated in Figure 1.

Experiment

Initially, the composting chamber of Biotoilet was filled with 26.4 kg of mixture wood sawdust (±75% volume). Then, 20.15L of tap water was added to achieve 50% of moisture due to optimize composting process. A mixer that has been installed in Biotoilet system is adjusted to run-on intermittenly with interval 15 min, each 2 min, i.e., 1 min for clockwise and counter-clockwise, respectively. Exhaust fan with flow rate of 0.04m3.sec-1 was

Table 1 Specification of Biotoilet Model Biolux S-15 (Seiwa Denko Co. Ltd, Japan).

|

Parameter |

Value |

|

Dimension: | |

|

Width (cm) |

151 |

|

Depth (cm) |

83 |

|

Height (cm) |

95 |

|

Weight (Kg) |

250 |

|

Power supply (Volt) |

100 |

|

Heater (Watt) |

25x12 |

|

Motor exhaust fan (Watt) |

200 |

|

Use standard (person/day) |

15 |

|

Amount of sawdust matrix (M3) |

0.5 |

operated continuously to ensure the composting system will go on with a proper aeration.

Socialization to the respondents about Biotoilet system and its procedures was conducted before in order to achieve a proper of utilization. Data of user, such as name, date, kind of usage (defecation/ urination or both), and body weight of user at before and after using of Biotoilet are recorded in table that has been available in room building. Body weight of user was measured by using balance that available also in room building.

There are two kind of water usage by respondents, i.e. for flushing closet bowl (if necessary) and for cleaning the body (normal). Water

Figure 1 Schematic diagram of composting toilet system (Nakagawa et al., 2006), room building for defecation and urination with Biotoilet reactor and closet bowl inside.

usage for flushing of toilet bowl is limited (300-500m per usage) due to keep the optimal moisture content of composting process (±50%). This flushing water would be mixed with human excreta and matrix material in Biotoilet chamber. Meanwhile, water for cleaning the body was at the side of toilet bowl which using a separated channel for disposal.

Human excreta, i.e. feces and urine were loaded daily from six persons for 76 days. Afterward, mixing and aeration was still operated in order to maintain the aerobic condition of Biotoilet system until at the 90th day. Residual sawdust that remained in biotolet chamber was harvested, noticed as Harvested Residual Sawdust (HRS), was then allowed for ten days at room temperature with proper aeration to obtain Composted Residual Sawdust (CRS).

Data observation and analysis

Human excreta loading which was consist of feces and/or urine was calculated as a difference body weight of respondents between before and after defecation and/or urination. Data could be obtained from the table form of Biotoilet usage. In this experiment, Biotoilet was not equiped with urine deverted. Therefore, both of feces and urine was mixed together in the composting chamber of Biotoilet.

Temperature at six points of sawdust pile, i.e. bottom, middle, and upper, both at inlet and outlet side of composter chamber was measured using a soil thermometer. Atmospheric temperature and humidity was measured with hygrometer. The samples that proportionally obtained from six points above were mixed properly and checked its moisture content and ash content. Moisture content was determined gravimetrically by heating of sample in oven at 105oC for 16 h (until achieve a constant weight). Meanwhile, pH value was measured by using the soil pH meter.

Nutrient content of sawdust that covering of N, P, and K was analyzed at Indonesian Vegetable Research Institute (IVEGRI) at Bandung. Ash content was determined by heating sample in furnace at 550oC for 16 h (modified SNI method) and calculated gravimetrically. Identification of the existing microorganisms of composted residual sawdust was carried out at the Medical Laboratory in Bandung, which covered of the Most Probable Number (MPN), bacteria, fungus, and worm ova. The characteristic of CRS that obtained in study was then compared to

EPA Standard part 503 according to the bio solid rule.

During study, Biotoilet was used 447 times, which covered of 328 times for urination and 119 times for both of defecation and urination. There is no usage by respondent just for defecation only. This fact could be undertood because in defecation is commonly accompanied with urination. Based on data obtained, 25.6kg fresh urine and 99.65kg of feces was loaded into composting chamber of Biotoilet (Table 2). Fresh urine production rate was in the range of 100-450g at one urinating, with the average was 215±97g. Considered to assumption that human have 6-8times urination per day, the average of urine production rate could be defined of 1,290-1,720 g.p-1.d-1. The previous studies reported that urine production rate was 1500g.p-1.d-1 (Jonsson et al., 2005); 1.42L.p-1.d-1 (Rose et al., 2015).

Data presented that the production rate of feces in study was variety, which in the range of 100-550g. If defecation of respondents is accounted one per day, production rate defecate material (feces-urine) could be defined of 304±124g.p-1.d-1 (Table 3). This result agreed with the earlier reports. Lower production was investigated in developed countries, i.e. 80-140g.p-1.d-1of fresh feces (Vinneras et al., 2006). Meanwhile, another research (Rose et al., 2015) reported the faecal wet mass production was 128g.p-1.d-1. In fact, feces quantity and quality depend on health condition, amount and type of food and liquid consumed. Food with high content of fiber result smaller amounts of feces than foods with low of fiber.

Temperature during composting

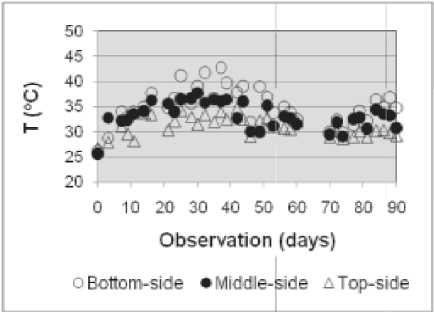

Data showed temperature of the bottom was higher than its middle and top-side of compost pile, with average of 35.00±3.71; 33.12±2.69; and 30.90±2.01, respectively (Figure 2-left). During study, temperature of atmospheric was in 22.50-29.00oC, or 26.34±1.53oC in average. While, temperature of composting system was in range of 26.00-37.45oC, or 32.93±2.57oC averagely (Figure 2-right). To expose sawdust in low-temperature zones to achieve higher temperature, compost pile should be mixed more sufficiently and repeatedly. In addition, to attain and keep high temperatures in entire pile,

Table 2 Input of human excreta in the composting process during study.

|

Code of User |

Frequency (times) Total input (g) Urinate Defecate+Urinate Urine Feces+Urine |

|

1 2 3 4 5 6 |

4 136 900 37,350 1 53 200 19,350 79 41 17,900 13,050 - 60 - 19,500 27 23 5,550 6,800 8 15 1,050 3,600 |

|

Total |

119 328 25,600 99,650 |

Table 3 The production rate of fresh feces and urine of respondents in study.

|

Code of User |

Production rate of urine(g.p-1) Production rate of feces+urine (g.p-1) Min Max Average Min Max Average |

|

1 2 3 4 5 6 |

150 300 225 100 600 275 200 200 200 100 600 365 100 450 227 150 500 318 - - - 100 600 325 100 450 206 150 550 296 100 200 131 150 400 240 |

|

Average |

- - 215±97 - - 304±124 |

Figure 2 Temperature during composting of human excreta: bottom, middle, and top side of pile (left); atmospheric air and Biotoilet system (right).

insulation should be provided to prevent heat loss, mainly for small compost heaps. Nevertheless, even insulation is provided, there will be parts of compost going on low temperature, mainly near inlet (closet bowl).

Compared to atmosphere, temperature of composting pile increased only 25%. It might be caused by the under loading of Biotoilet. Durting study, the Biotoilet usage is under capacity, i.e. only 6p.d-1 or equal with 40% of standard usage (15p.d-1). It was investigated that the under loading of organic material, both of feces and urine could be as an inhibiting factor in composting transition from mesophilic to thermophilic phase due to limited of self heating capability (Eftoda and McCartney, 2004).

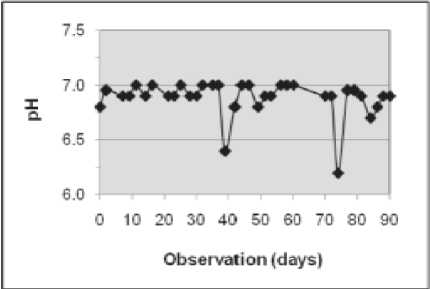

Moisture content and pH level of sawdust matrix

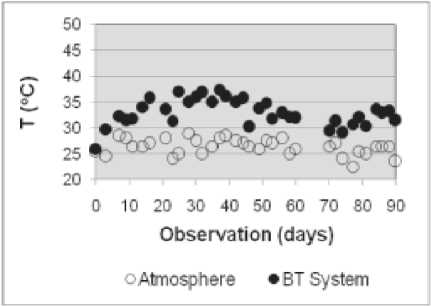

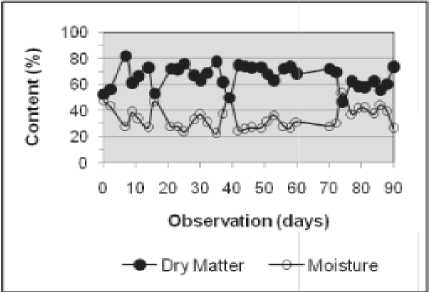

Naturally, moisture content of local wood sawdust was 11.84%. This moisture level was adjusted to optimal moisture for composting (± 50%) by added water. In fact, bad odor was not detectable during the composting process in study. It might be supported by the level of moisture content of sawdust pile, which could be kept in the range of 22.27-53.20% with the average of 33.46% (Figure 3-left). In general, when moisture content of compost pile was low (<40%), unpleasant odors would be significantly less noticeable (Banegas et al., 2007).

Ahn et al (2008) reported the optimum moisture for composting is 25-80%. A wide range of optimum moisture for composting reflects the different structural properties of substrates. Highly structure substrates, such as wood chips, can be composted at high moisture contents, whereas poorly

substrates, such as food waste, require lower moisture content to compost. Most substrates with moisture content more than 60% may produce anaerobic conditions due to water-logging. This condition inhibits aerobic degradation and resulting acid substances and smell. Odour associated with toilets is a primary concern of users.

Composting is a microbiological degradation of organic material to a humus-like product under aerobic, moist and self heating conditions (Banegas et al., 2007). The microorganisms involved in aerobic composting should be supplied with oxygen, such as by mechanical aeration and physical turning of the compost pile. In this study, oxygen was supplied by combining of the using of mechanical mixing, exhausting, and an appropriate of matrix. Sawmill industry waste material has some benefit characteristic as matrix due to its high porosity that make it possible to store oxygen, low in bulk density, high of water holding capacity, and high durability (Funamizu, 2006).

In initial phases of composting, pH usually declines due to the formation of organic acids that are produced through fermentation of easily degradable organic matter. Finally, pH rises due to the acids are consumed by microorganism and ammonia is produced. During process, pH level was fluctuated in the range of 6.20-7.00, with the average of 6.88±0.17 (Figure 3-right). The pH level of composted residual sawdust (CRS) is 6.9 and suitable for most commmodity of agricultural. This level is near with Lembang soil that has pH 7.0, and higher than Jatinangor soil pH 6.0. In fact, pH level of sawdust matrix at the 39th and 74th day was

Figure 3 Moisture content (left) and pH (right) of matrix during composting human excreta.

significantly dropped to 6.40 and 6.20, respectively. The decreasing of pH might be caused by the high moisture content of sawdust during composting. Data presented that moisture content of sawdust at the 39th and 74th day was more than 50%.

C/N ratio and nutrient content

The C/N ratio is considered among the factors affecting the compost process and quality. In growing, microorganisms require digestible carbon for energy and nitrogen for cell synthesis. It was reported that the ideal of C/N ratio for composting toilets is 15-30. It was investigated that if the C/N ratio of substrate is low (<15), the excess nitrogen content would be lost via ammonia volatilization that mainly occur at a high pH and temperature. As the result, value of compost as fertilizer would decrease due to loosing of N content. In contrast, if initial C/ N ratio is greater than 35, microorganisms must go through many lifecycles, including of oxidizing off excess carbon until suitable of C/N is reached (Eklind et al., 2007).

In study, C/N ratio of sawdust matrix decreased significantly, i.e. from 566 to 25 (Table 4), near with soil, both of andosol and latosol that has C/N ratio are 23 and 20, respectively. It could be concluded that sawdust from local sawmill industry could be used as matrix in composting of human excreta and resulting compost with appropriate of C/N ratio level. In composting, organic compounds in sawdust matrix, mainly feces and urine would be degraded by aerobic bacteria resulting carbon dioxide (CO2) and water (H2O) which then be released to atmosphere. The microbial cells undergo progressive autooxidation of the cell mass. Nutrient elements such as N, P, and K would be accumulated in sawdust that can be used as fertilizer (Banegas et al., 2007).

Ash content of composted residual sawdust in study is 11.78%, increased significantly compared

to its initial (4.30%). Ash content of sawdust compost in study is higher than albizzia sawdust (7.11%) as reported by Triastuti et al (2008). Data showed that composted residual sawdust have high content of N, P and K. Compared to the nutrient content of soil, both of Lembang and Jatinangor soil, CRS has higher concentration in all macro nutrients content, i.e. N 1.78%, P 0.85%, and K 0.95% as presented in Table 4 above. This high content of mineral could be made the CRS more benefit for agricultural.

The existing of microorganism in compost

Table 5 presented MPN faecal coliform of sawdust matrix was decreased significantly during composting, i.e. from 2.4x106 (the 14th day) to 9.3x104 in harvested residual sawdust (HRS), and finally dropped to 23cells.g-1 in composted residual sawdust (CRS). Bacteria Proteus mirabilis, Enterobacter aglomerans, Enterobacter aerogenes, and Staphylococcus saprophyticus were not detected, both in HRS and CRS. Fungus, such as Penicillium sp and Aspergillus sp was not occurred, but Klebsiella pneumonia and Escherichia coli were still detected in the CRS although only in small quantity. Worm ova were undetected in CRS.

Similar to solids obtained from traditional wastewater treatment, the solid from composting toilet can be used as fertilizer (Anand and Apul, 2014). Nevertheless, its utilization must consider to the health safety regulation, including of microbiological aspect. Based on MPN fecal coliform, there are three classes of compost, i.e. class A, B, and C with classification as presented in Table 6 (EPA standard, 1994). By referred to the EPA standard, compost that obtained in study could be categorized into class A, that safe level and acceptable of the pathogen and safe soil amendment for cultivation both of non-food and food plants commodity.

Table 4 Nutrient elements of sawdust compared with soil.

|

Material |

pH |

C/N ratio |

N (%) |

P (%) |

K (%) |

|

Natural sawdust |

6.8 |

566 |

0.08 |

0.27 |

0.50 |

|

Composted Residual Sawdust |

6.9 |

25 |

1.78 |

0.85 |

0.95 |

|

Lembang soil (Andosol) |

7.0 |

23 |

0.15 |

0.39 |

0.11 |

|

Jatinangor soil (Latosol) |

6.0 |

20 |

0.05 |

0.17 |

0.11 |

Table 5 The existence of microorganisms in sawdust matrix during composting.

|

Microorganisms |

Composting period | ||

|

14th day (Initial) |

90th day (HRS) |

100th day (CRS) | |

|

MPN Coliform (cell.g-1) |

2.4x106 |

2.4x105 |

23 |

|

MPN Faecal Coliform (cell.g-1) |

2.4x106 |

9.3x104 |

23 |

|

Klebsiella pneumonia |

+ |

+ |

+ |

|

Escherichia coli |

+ |

+ |

+ |

|

Proteus mirabilis |

+ |

- |

- |

|

Enterobacter aglomerans |

+ |

- |

- |

|

Enterobacter aerogenes |

+ |

- |

- |

|

Staphylococcus saprophyticus |

+ |

- |

- |

|

Penicillium sp |

+ |

- |

- |

|

Aspergillus sp |

+ |

- |

- |

|

Worm ova |

+ |

- |

- |

Note : + (detected) - (undetected)

Table 6 Classification of compost (EPA Standard, 1994).

Class MPN Fecal Coliform (cells.g-1) Recommendation

|

A |

N ≤ 1.103 |

|

|

B |

1.103 < N d” 2.106 |

|

|

C |

N > 2.106 |

|

Prospect of lignocelluloses waste material for composting human excreta using Biotoilet

Biotoilet is a dry toilet, which is not require of flushing water. Implementation of this technology would be an alternative to solve a sanitation problem in area with inadequate sewage disposal and limit of water. By this new system a sewage infrastructure can be replaced and water usage can be reduced. In addition, residual sawdust could be used as a soil conditioner that able to improve the soil quality (Funamizu, 2006).

West Nusa Tenggara province of Indonesia has a long of dry season and low of rainfall. The period of dry season usually is in April to November (8 months), while the rainy season is in December to

March (4 months). The rainfall in rainy season is only 421-526mm. the rainfall in another month is commonly less than 290mm, and even sometimes less than 100mm. The condition of East Nusa Tenggara province is similar with West Nusa Tenggara province. Considered to the natural condition of West Nusa Tenggara province, implementation of Biotoilet with using sawdust matrix for composting human excreta is suggested have a good prospect. In addition, Biotoilet might be also suitable to improve sanitation in a slum urban area, such in Kiaracondong sub district, Bandung city due to its limited of open space area and unappropriate of sewages disposal.

The characteristics of matrix material, durability,

and its availability should be considered related with its utilization for Biotoilet in future. Data showed that wood sawdust is continuously available in Nusa Tenggara Barat province. It was reported that the forestry area in Nusa Tenggara Barat province achieved 50.69% of total area with production of wood in year 2012 was 22,306 m3 (BPS, 2013). From this material, about 1,896 m3 of mixture wood sawdust would be resulted. The implementation of sawdust as matrix could be also saved in West Java province due to its continuous availability. Data presented wood production of West Java province in year 2013 was 247.155m3(BPS, 2014). Mixture wood sawdust would be resulted, i.e. 8.5% wood production, or approximately 21,008 m3.

Beside of wood sawdust, some agricultural residues could be used also as matrix, such as rice straw, rice husk, corn stalk, coconut shell etc. The utilization of each material as matrix must be synchronized with its availability in place to maintain the continuity in supply and sustainability in application of Biotoilet system.

Nevertheless, implementation of composting of human excreta should be integrated with the utilization of compost product for agricultural. However, the value, perception and management of water and sanitation depend on the root culture, religion beliefs and taboos about human excreta. The choice of sustainable sanitation concept have not been investigated yet sufficiently, mainly in Muslim community (Nawab et al., 2006). It was reported that 85.2% of human excreta in China is utilized as manure for agriculture, 3.6% as biogas, and 11.2% discharged to water body, septic tank, and soil (Liu et al., 2014).

In Indonesia, compost of human excreta for agriculture might be not acceptable yet due to social-cultural barrier. In contrast, sustainable sanitation cannot be realized unless a fundamentally different way of thinking about sanitation has been adopted, which is including of the major changes in personal beliefs, values, and life styles. Therefore, the appropriate approach is required to motivate people to adopt the Ecosan concept for sanitation improvement, water pollution and soil degradation prevention. Firstly, utilization of composted human excreta for cultivation of non-food commodity, such as forestry and ornamental plant might be cultural acceptable. This step is one of strategy how to replace partly of chemical fertilizer for agricultural.

Compared to atmospheric, the average temperature of composting system was 25% higher, i.e. 32.93±2.57oC. Moisture content of matrix was in the range of 22.27-53.20%, and pH level 6.20-7.00. Bad odor was not detectable during composting. CRS with C/N ratio 25:1 is suitable for compost. Ash, N, P, and K content of CRS were 11.78; 1.78; 0.85; and 0.95%, respectively. It could be concluded mixture wood sawdust could be used as matrix in composting of human excreta using Biotoilet. Based on EPA standard, the compost could be categorized into class A and safe for cultivation, both of nonfood and food plants. Application of this compost in agricultural should be considered to evaluate its characteristics as fertilizer and its compatibility for plant.

Acknowledgement

This study was funded by Indonesian Institute of Sciences (LIPI) and supported by Japan Science and Technology Agency (JST) in sustainable sanitation joint research. Thanks to Dr. Mitsuteru Irie and Dr. Ken Ushijima for guidance and Ibu Mimin for good assistance.

References

Ahn, H.K., Richard, T.L. and Glanville, T.D. 2008.

“Optimum moisture levels for biodegradation of mortality composting envelope materials”. Waste Manag, 28. 1411-1416.

Anand, C.K, and Apul, D.S. 2014. “Composting Toilet as a sustainable alternative to urban sanitation”. Waste Manag. 34: 329-343.

Banegas, V., Moreno, J.L., Garcia, C., Leon, G., and Hernandez, T. 2007. “Composting anaerobic and aerobic sewage sludge using two proportions of sawdust”. Waste Manag. 27, 1317-1327.

BPS Nusa Tenggara Province. 2013. Production of wood in Nusa Tenggara Barat 2012. Nusa Tenggara Barat in Figure 2013. p. 312.

BPS.Jawa Barat Province. 2014. Wood production in Jawa Barat 2013. Jawa Barat in Figure 2014. pp. 257-258.

Eftoda, G. and McCartney, D. 2004. “Determining the critical bulking requirement for municipal solid

biosolids composting”. Compost Sci. Util. 12 (3). 208-218.

Eklind, Y., Sundberg, C., Smars, S., Steger, K., Sundh, I., Kirchmann, H. and Jonsson, H. 2007. “Carbon turnover and ammonia emission during composting of biowaste at different temperature”. J. Environ, Qual., 36. 1512-1520.

EPA., 1994. A plain English guide to the EPA part 503 bio solid rule. Office of Wastewater Management. US-EPA.

Funamizu, N., 2006. Function of composting toilet and its design. Proceedings of The 4th International symposium on Sustainable Sanitation. Bandung, Indonesia, 4-6 September 2008. 1-10.

Iqbal, M.K., Shafiq, T., and Ahmed. K. 2010. “Characterization of matrix and its effect on physical properties of compost”. Proceedings of The 4th International symposium on Sustainable Sanitation. Bandung, Indonesia, 4-6 September 2008. Bioresour. Technol., 101. 1913-1919.

Jhamaria, C., and Yadav, R.K. 2014. “Environmental Biotechnology: Achievements, perception and prospects: A Review”. Res. J. Chem. Env. Sci. 2 (1). 01-13.

Jonsson, H., Baky, A., Jeppsson, U., Hellstrom, D., and Karrman, E. 2005. “Composition of urine, feces, grey water and bio-waste for utilization in the URWARE”. Model. Report, Urban Water, Chalmers, Sweden.

Langergraber, G., and Muellegger, E. 2005. “Ecological Sanitation-a way to solve global sanitation problems” Elsevier. Environment International. 31. 433-444.

Liu, T., Huang, J.K. and Zikhali, P. 2014. “Use of Human Excreta as Manure in Rural China”. Journal of Integrative Agriculture. 13 (2). 434442.

Nakagawa, N., Otaki, M. and Ishizaki, K. 2006. Application of microbial risk assesment on SUSSAN System in Miyako island. Proceedings of The 4th International symposium on Sustainable Sanitation. Bandung, Indonesia, 4-6 September 2008. 86-94.

Nawab, B., Nyborg, I.L.P., Esser, K.B. and Jenssen, P.D. 2006. “Cultural preference in designing ecological sanitation systems in North West Frontier Province, Pakistan”. Journal of Environmental Psychology, 26 (3). 236-246.

Rose, C., Parker, A., Jefferson, B., and Cartmell, E. 2015. “The cahacterization of feces and urine: A review of the literature to inform advanced treatment technology”. Critical Review in Environmentyal Science and Technology. 45. 1827-1879.

Saranraj, P. and Stella, D. 2014. “Composting of sugar mill wastes: A Review”. World Applied Sciences Journal. 34 (12). 2029-2044.

Sheng, L., Sun, S., Gao, L., and Duan, L. 2005. Study on the feasibility of using corn stem as a matrix in Biotoilet. Proceeding of International Water Association (IWA) Conference: Future of Urban wastewater system. Decentralization and Reuse. Changchun, China. 29 September 2008-1 October 2008. 225-234.

Astuti, J.T. and Neni Sintawardani. 2006. The present situation of public toilet in Kiaracondong, Bandung city, Indonesia: A preliminary study of Biotoilet application. Proceedings of The 4th International symposium on Sustainable Sanitation. Bandung, Indonesia, 4-6 September 2008. 53-60

Triastuti, J., Sintawardani, N., and Irie, M. 2008. “Physical and chemical characteristic of Albizzia sawdust as matrix in the decomposition of human excreta using Biotoilet”. Journal of Tropical Wood Science and Technology, 6 (1). 26-32.

Vinneras, B., Palmquist, H., Balmer, P., and Jonsson, H. 2006. “The composition of household wastewater and biodegradable solid wasteproposal for new norms for the flow of nutrients and heavy metals”. Urban Water J. 3. 3-11.

WHO, 2006. WHO-guideline for save reuse of wastewater, excreta and grey water. Vol. 1.

WSP, 2008. Economic Impacts of sanitation in Indonesia. Research Report August 2008. Water and Sanitation Program (WSP) East Asia & Pacific. World Bank, Jakarta.

48

Discussion and feedback